Particle solid sample parallel double-sample preparation device

A preparation device and solid-state technology, which is applied in the field of solid-state sample shrinkers, can solve the problems of inability to achieve cutting frequency, difficulty in ensuring sample preparation accuracy, and easy suspension in the air, so as to facilitate sample transfer and clean equipment, avoid dust loss and Cross-interference, the effect of increasing the number of effective fills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

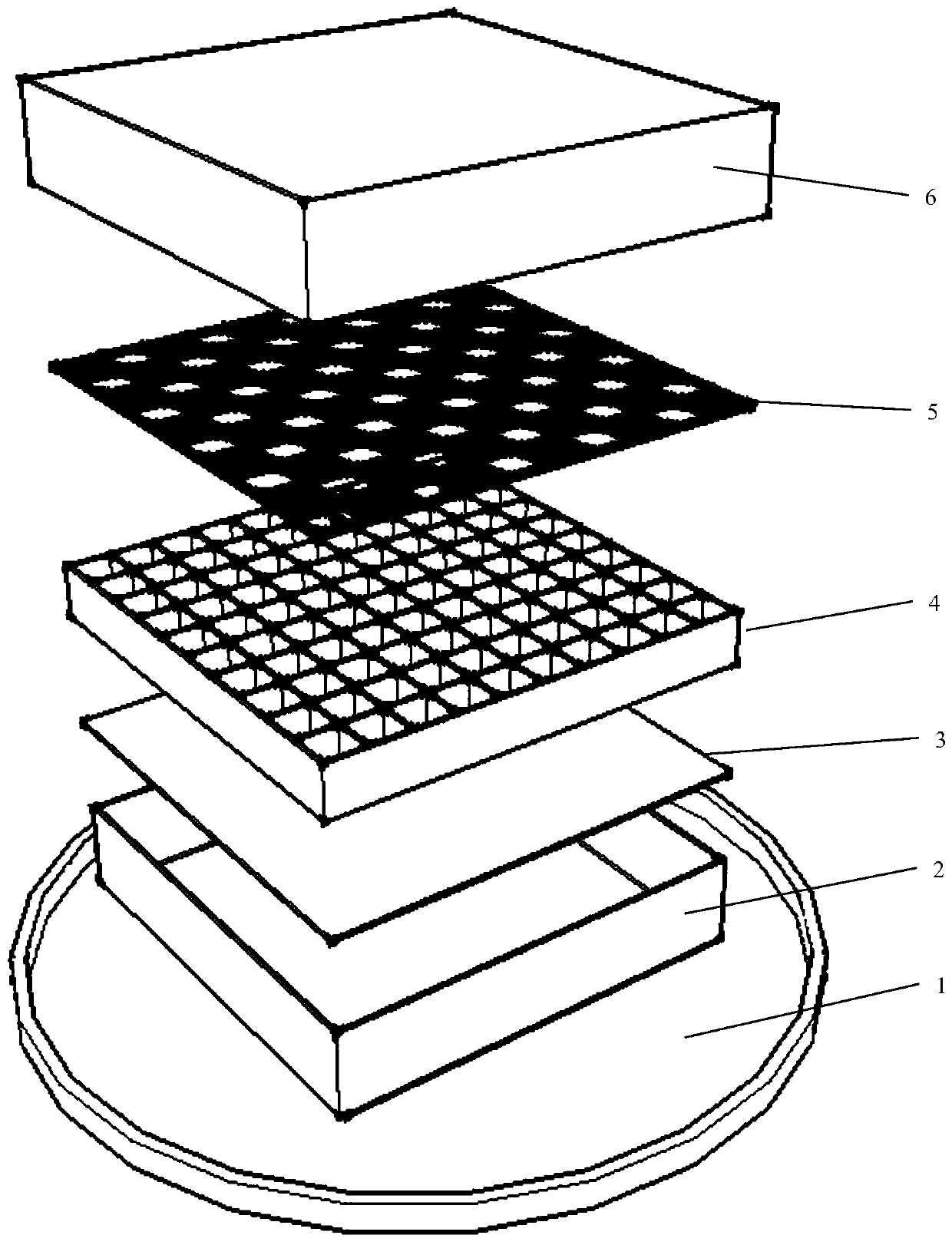

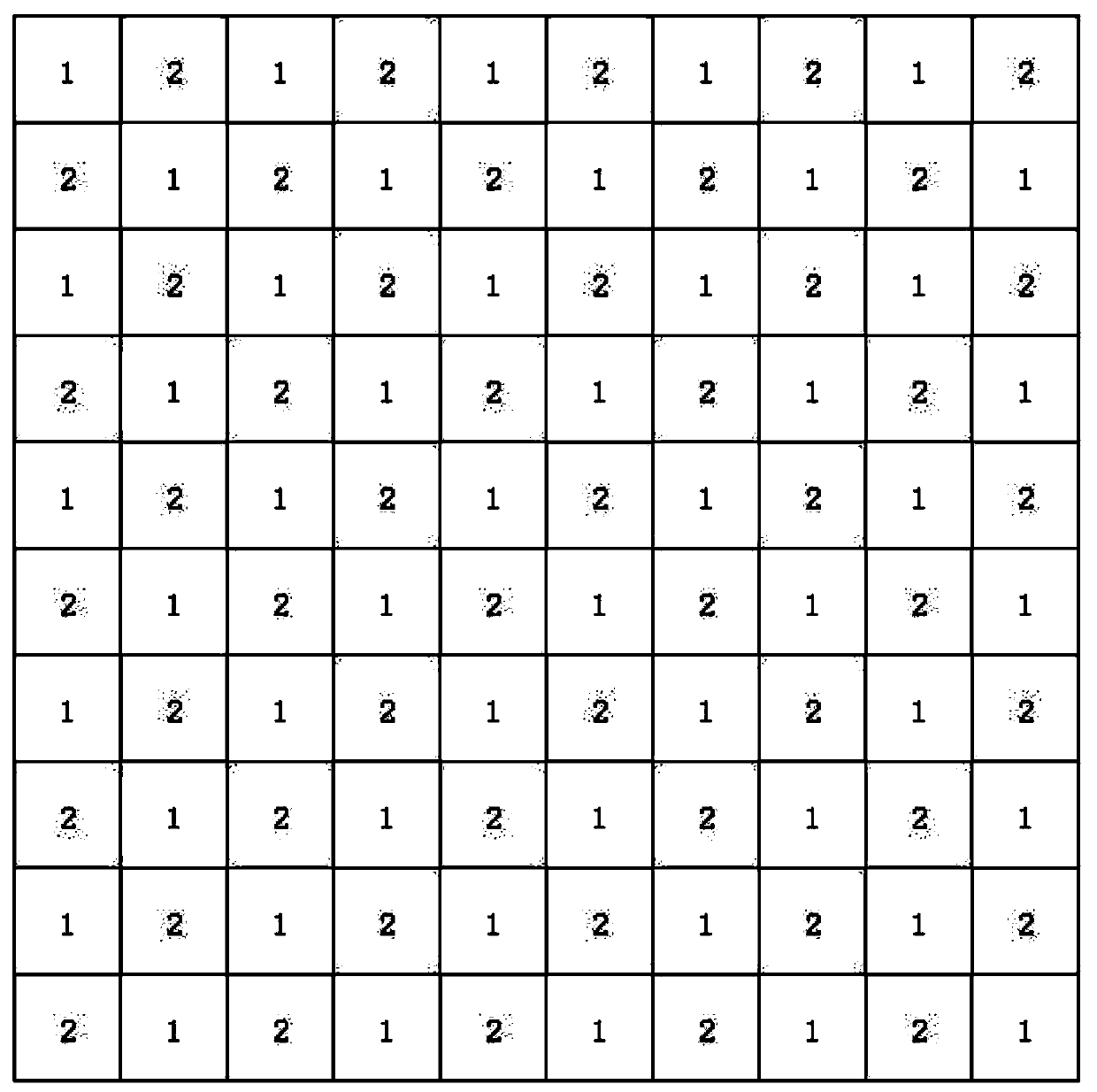

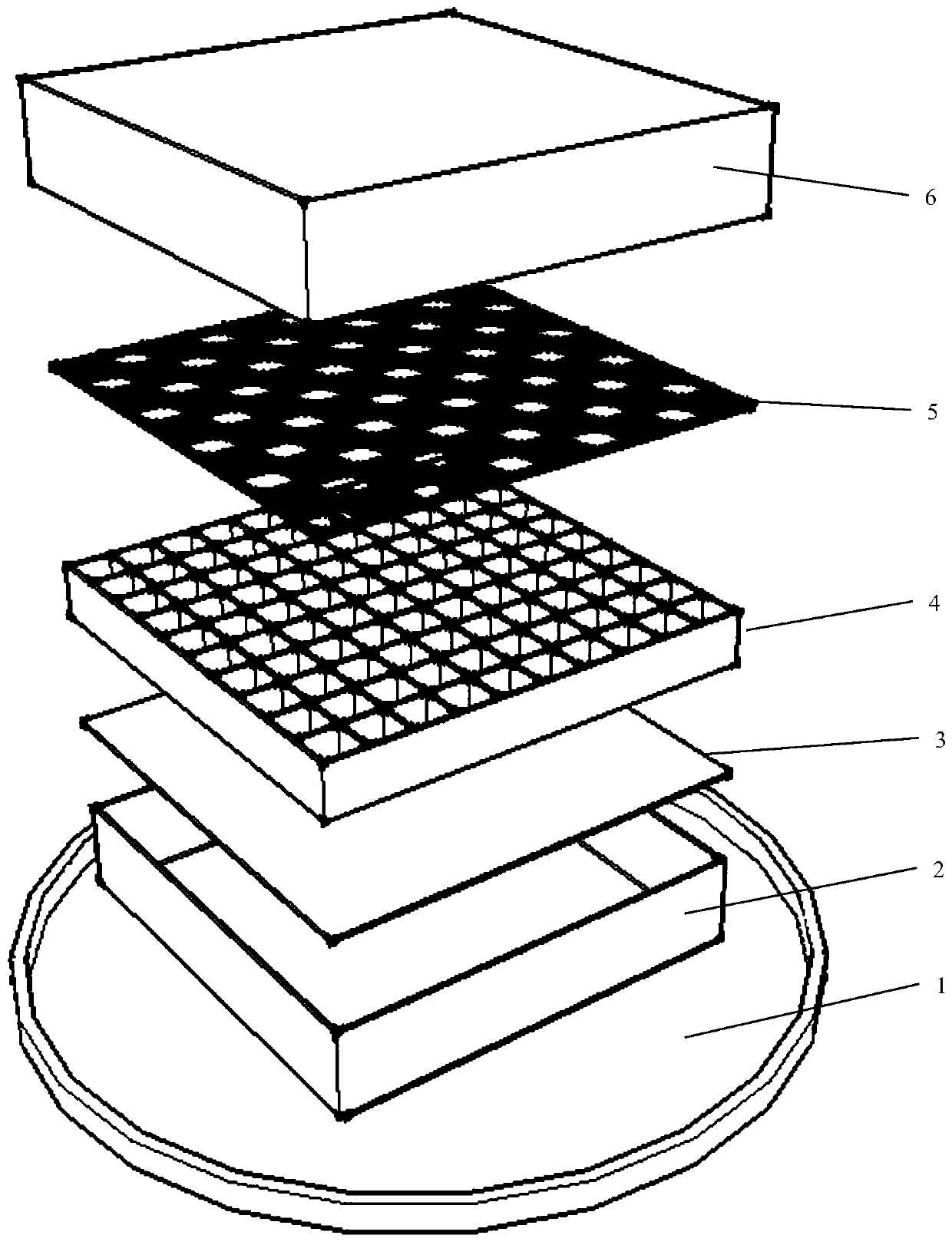

[0021] figure 1 Middle, recovery tray 1, lower sub-sample box 2, lower lining board 3 (with adjustable height feet), checkerboard divider 4, sub-sample plate 5 (corresponding to the size of the checkerboard divider, and the single number grid is hollowed out, See figure 2 ), the upper sub-sample box 6.

[0022] Such as figure 1 As shown, the high-precision parallel double-sample preparation device for fine-grained solid samples below 0.25 mm: the recovery tray 1 is placed at the bottom, and the lower sample box 2 is placed on the recovery tray 1; according to the sample volume, select a checkerboard partition with an appropriate height 4, and after adjusting the height of the feet of the lower liner 3, place the lower liner 3 in the lower sample box 2, and place the checkerboard divider 4 on the lower liner 3. At this time, the checkerboard divider 4 The upper end and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com