Bridge crane system control method based on sliding mode control theory

A technology of control theory and control method, applied in the field of bridge crane system control based on sliding mode control theory, can solve the problems of low efficiency and high requirements of crane drivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

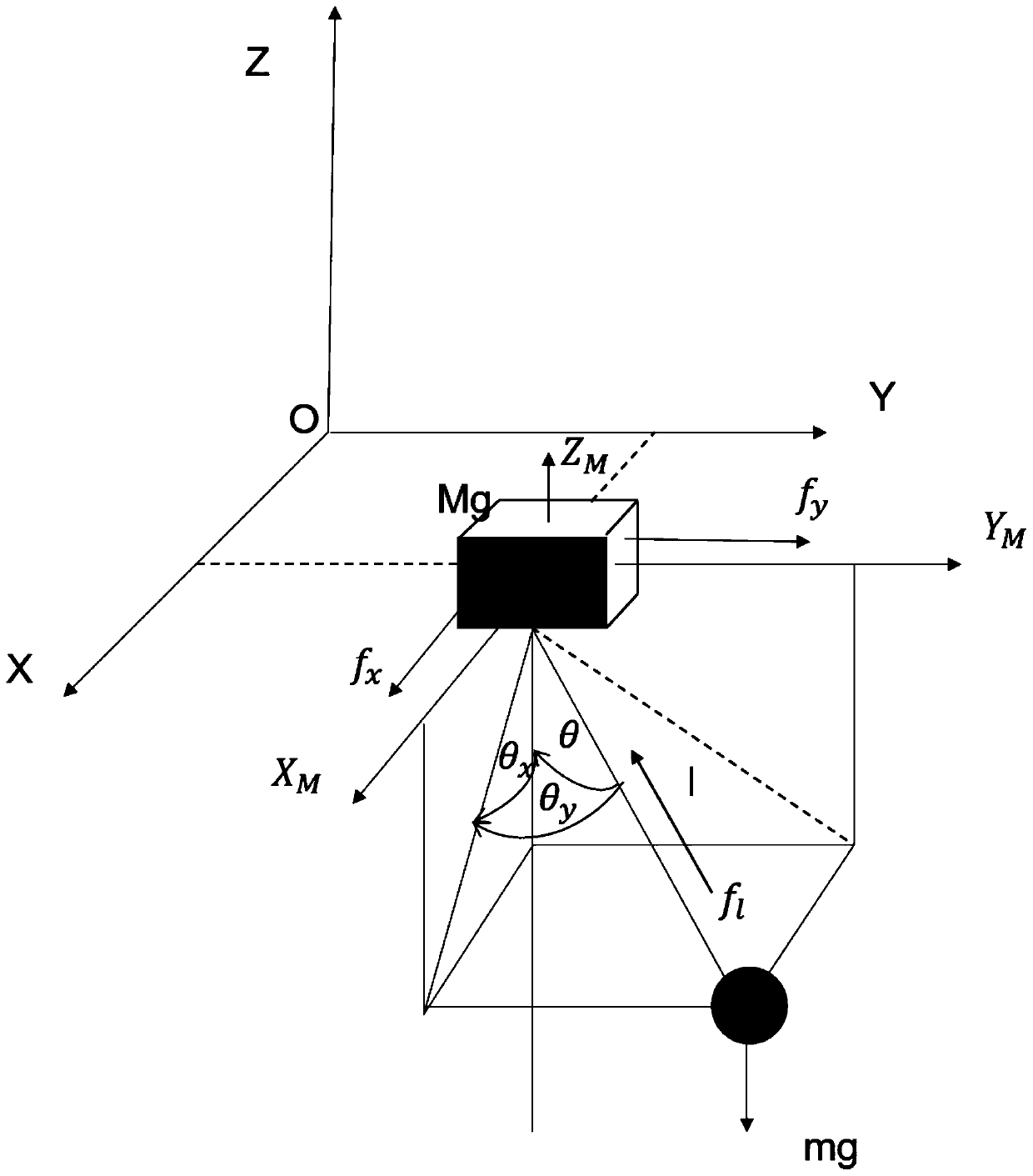

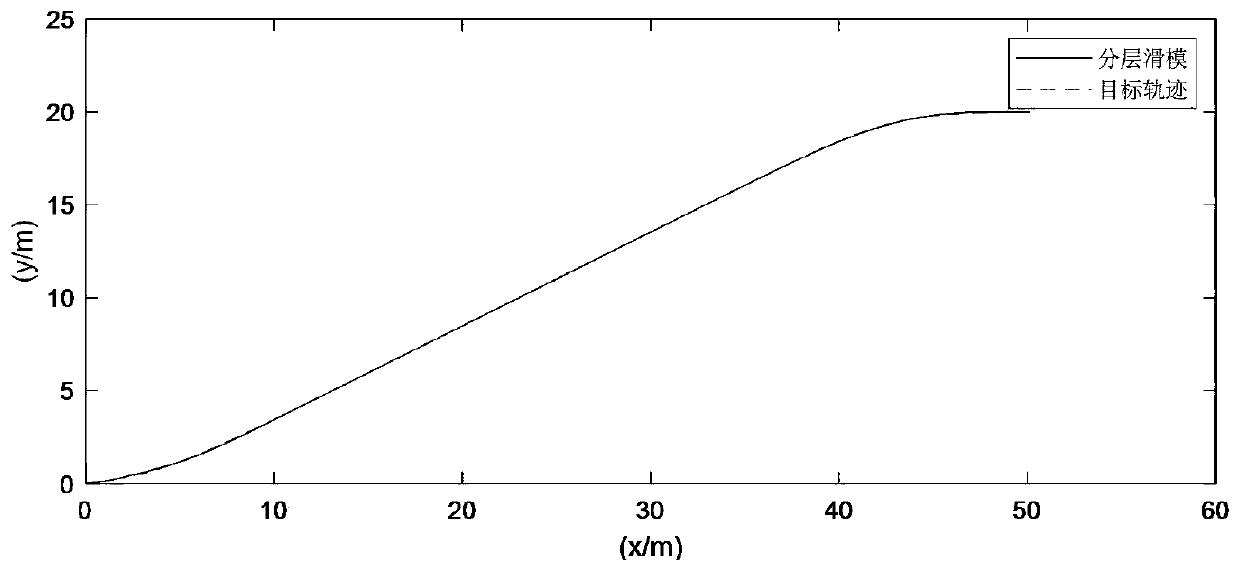

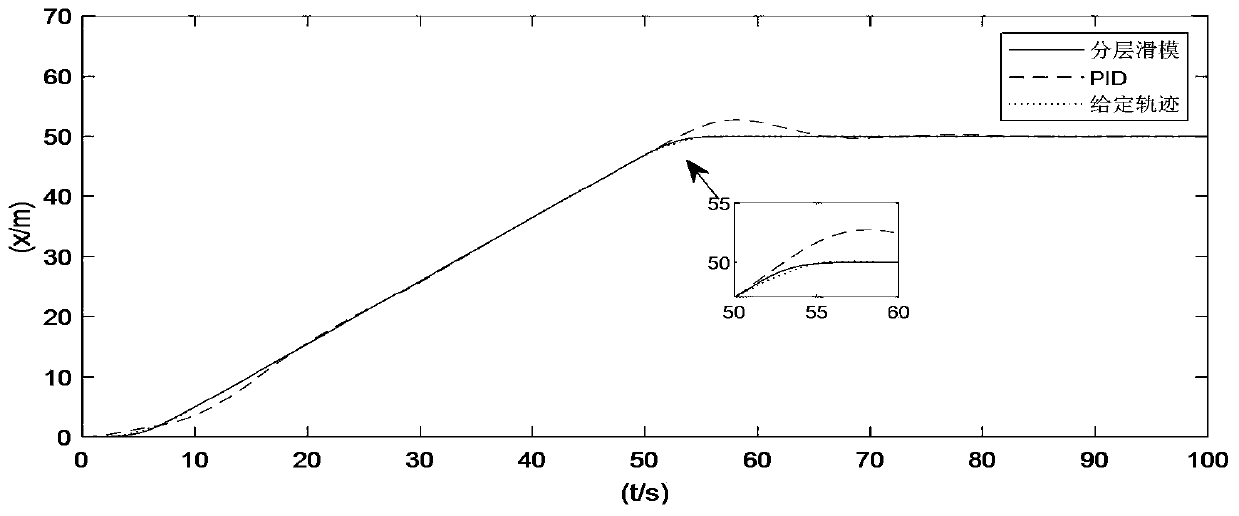

[0026] Sliding mode control is also called variable structure control. Its nonlinear characteristics are manifested as control discontinuity. It can continuously change the structure of the system according to the current state of the system, forcing the system trajectory to gradually stabilize to the equilibrium point according to the predetermined sliding mode. The sliding mode variable structure control problem can be decomposed into a comprehensive problem of two low-dimensional subsystems, that is, designing the variable structure control law to make the system state reach the selected sliding mode within a limited time and selecting an appropriate switching function to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com