Dynamic modeling method for aircraft high-lift system

A technology of system dynamics and modeling method, which is applied in the field of aircraft high-lift system dynamics modeling, can solve the problems of high-lift system such as poor economy, high price, and high protection threshold, so as to solve the bottleneck problem of development and facilitate the solution , the effect of less model degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

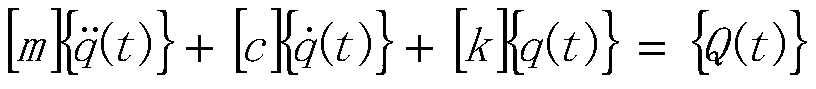

[0024] A method for modeling dynamics of an aircraft high-lift system, comprising the following steps:

[0025] Step 1: Calculate the stiffness k of all torsion tubes between the individual actuators eq , the calculation formula is: in G is the shear modulus of the torque tube material, I i is the moment of inertia of the cross-section of the i-th torsion tube, L i is the length of the i-th torque tube.

[0026] Step 2: Establish a mathematical model of the reducer in the transmission line;

[0027] The mathematical model of the reducer in the transmission line is: In the formula, θ in (t) is the angular displacement of the input end of the reducer, n is the reduction ratio of the reducer, θ out (t) is the angular displacement of the output end of the reducer, is the angular acceleration at the input end of the reducer, is the angular acceleration at the output end of the reducer.

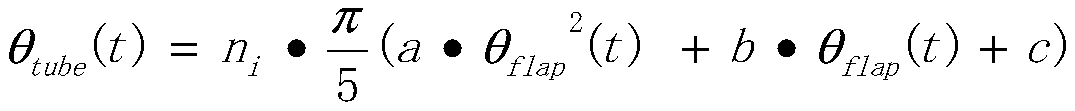

[0028] Step 3: Establish a combined mathematical model of the composite mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com