Continuous deoiling machine for surface of drop pill products

A deoiling machine and product technology, applied in non-progressive dryers, devices that make medicines into special physical or ingestible forms, dryers, etc., can solve the problem of continuous deoiling of the surface of dripping pills With online cleaning function, it is easy to affect the deoiling effect and other problems, so as to achieve the effect of reducing labor intensity, reducing oil content and utilizing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

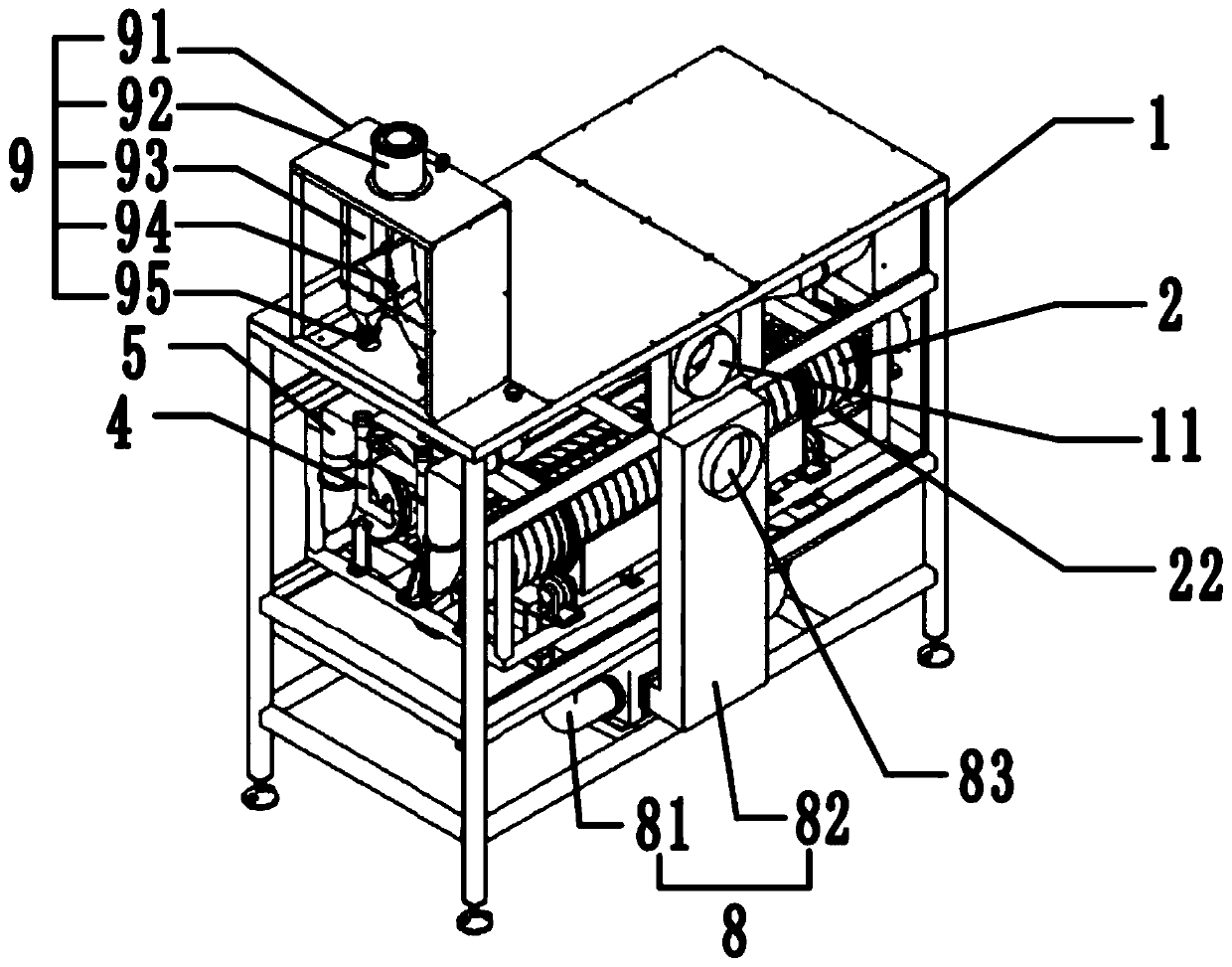

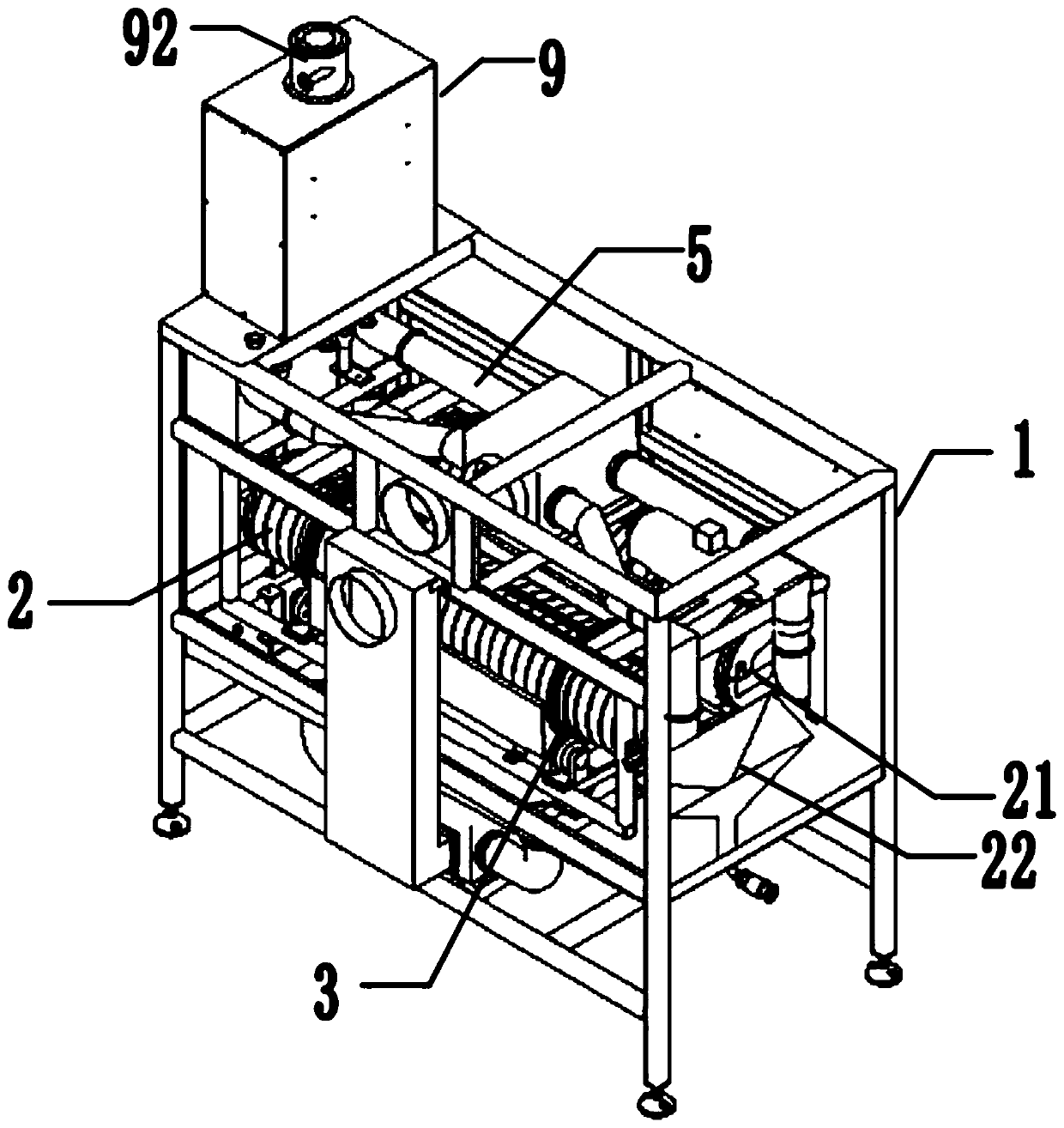

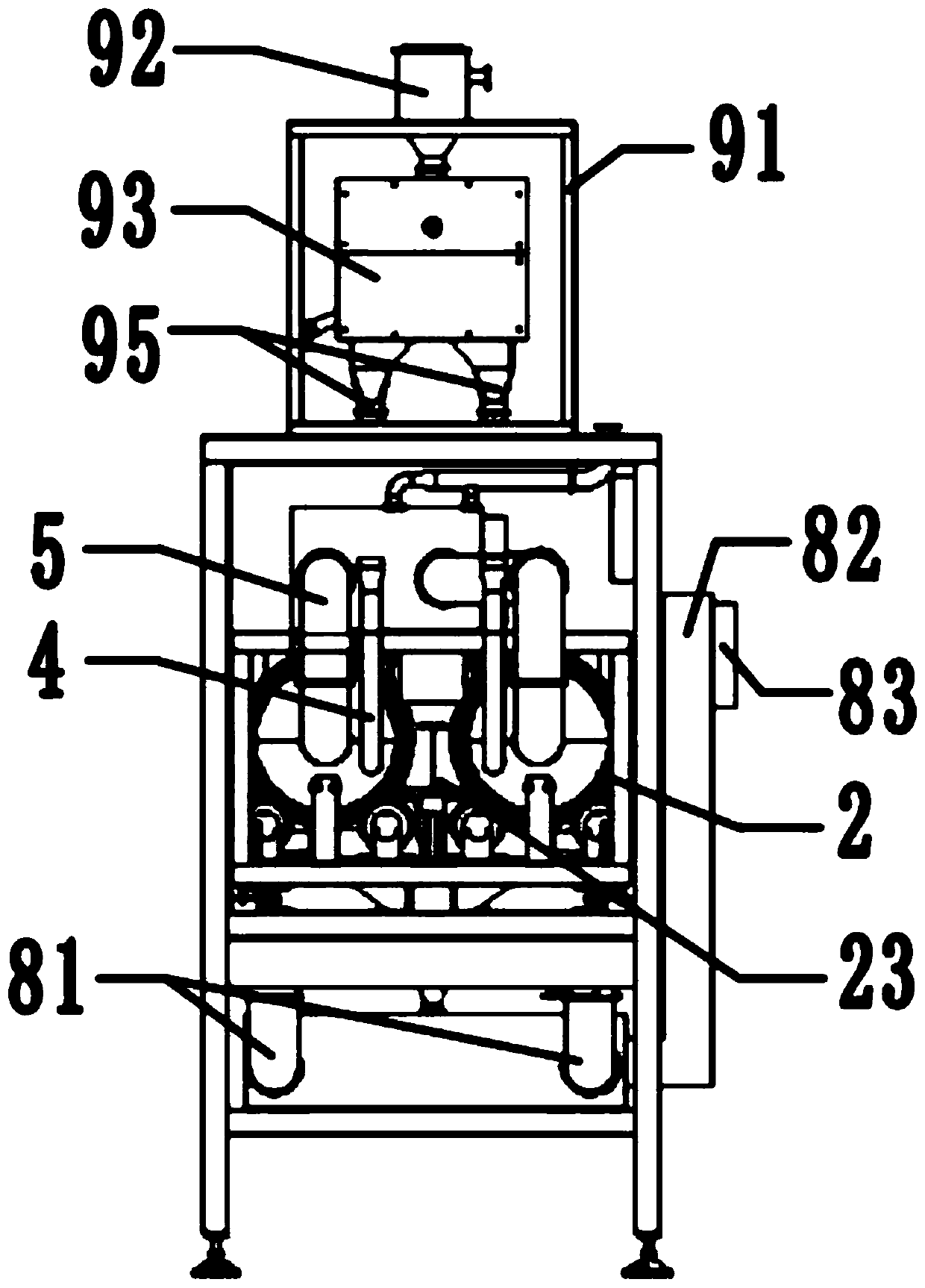

[0041] Such as figure 1 with figure 2 Shown, a kind of dripping pill product surface continuous deoiling machine, comprises casing 1, two groups of drums 2 arranged adjacently in casing 1, and the drive mechanism 3 that drives drum 2 to rotate, two groups of drums One end of the drum 2 is inserted into the feed pipe 4, and the inner cavity of the drum 2 runs through the air inlet pipe 5, which is connected to the treated external clean and dry air source, and the air inlet pipe 5 is evenly distributed along its axis Multiple groups of air holes are used to blow the dripping pills that are transported from the feed port of the drum 2 to the discharge port 21 in the cavity of the drum 2 .

[0042]Specifically, an air inlet 11 is provided on the casing 1, and the air inlet 11 communicates with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com