High-intensity focused ultrasonic transducer

A technology of focused ultrasound and transducers, which is applied in the field of medical devices, can solve the problems of cumbersome contact reliability of leads, large cumulative assembly errors, and many assembly links, so as to reduce mechanical sensitivity, reduce dimensional errors, and achieve high installation and positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

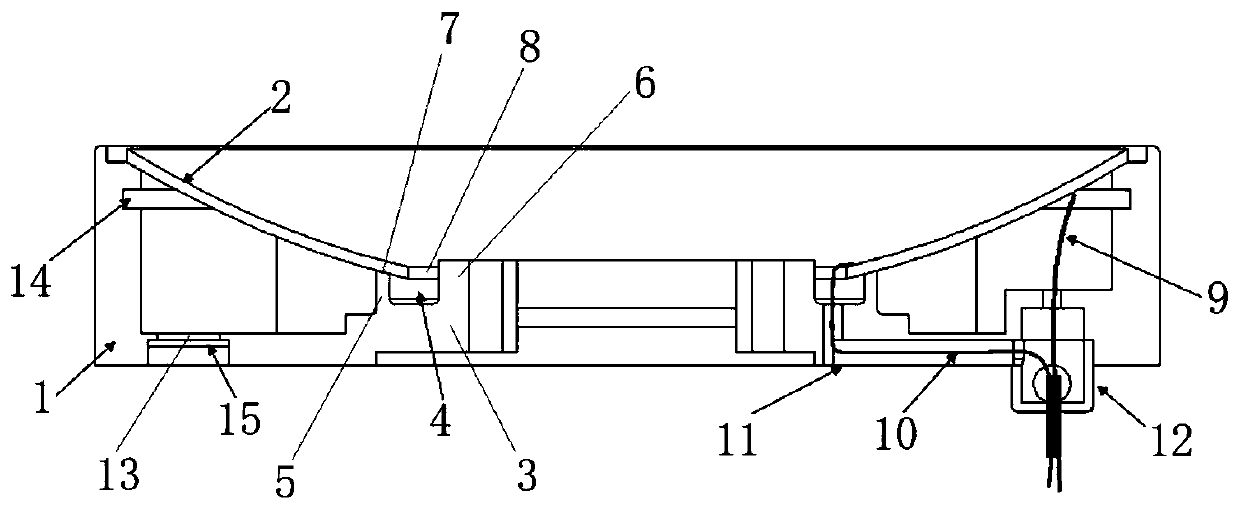

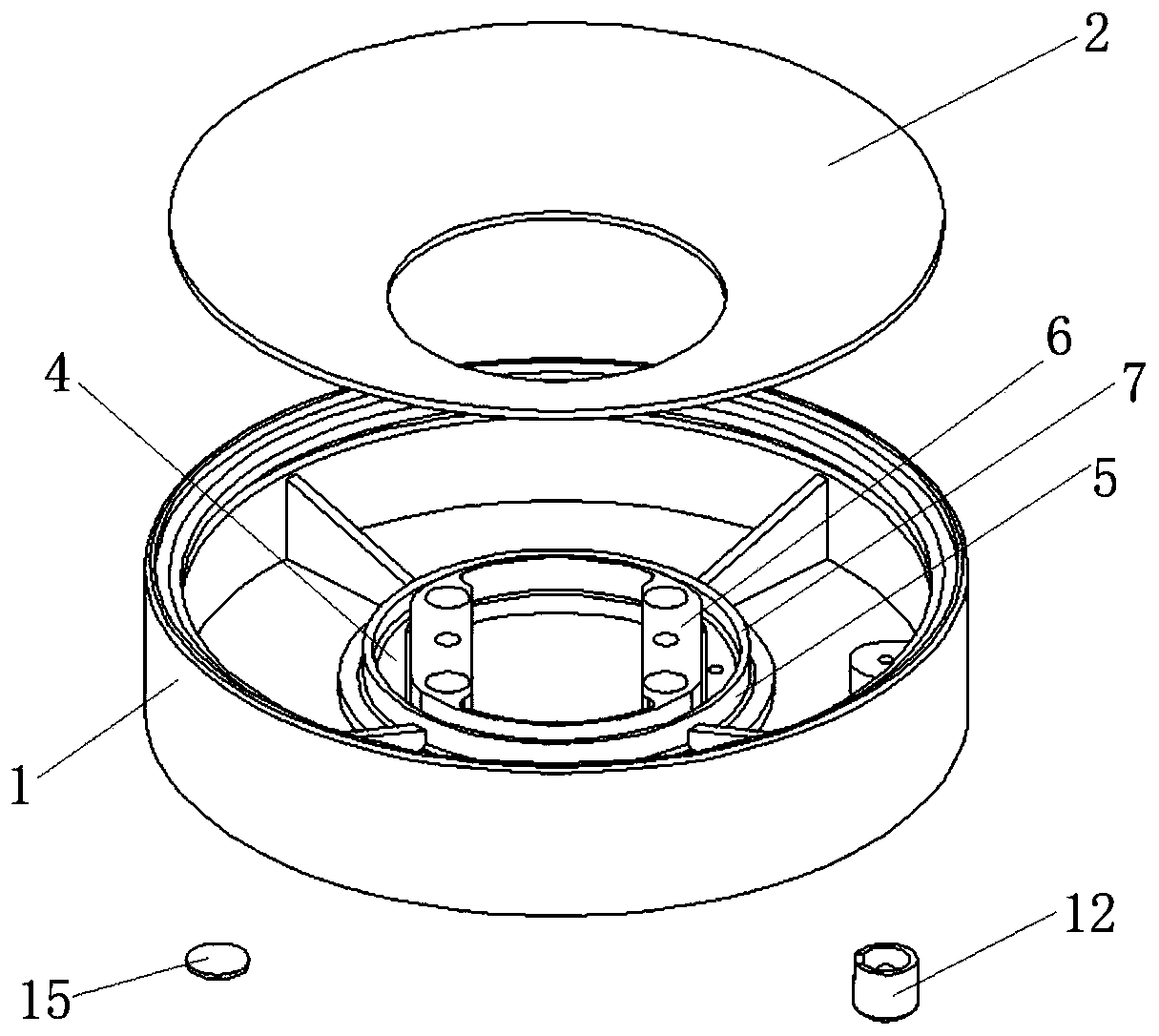

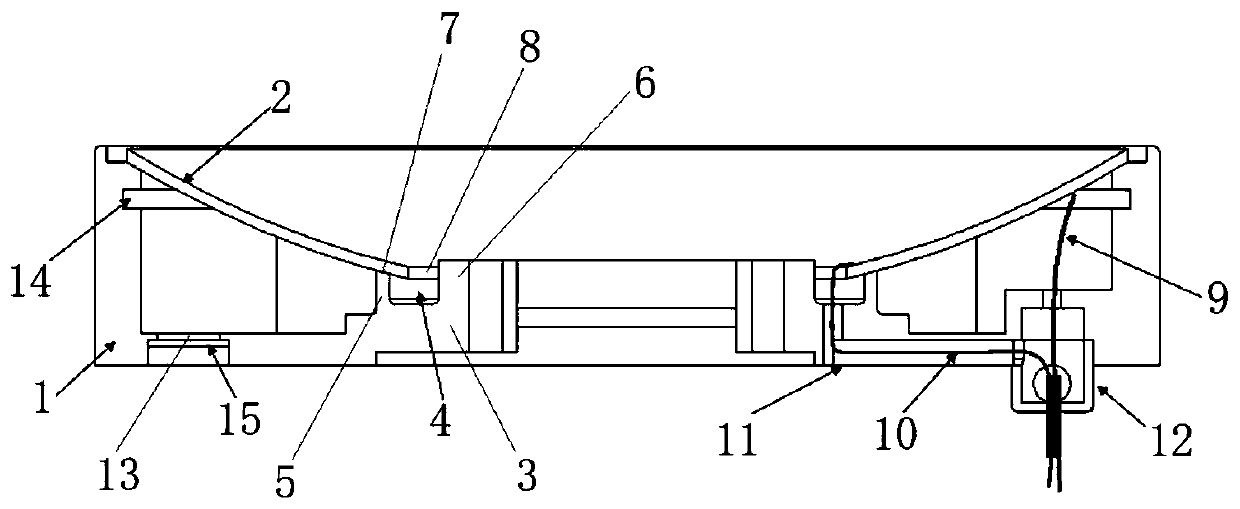

[0022] Such as figure 1 and 2 As shown, a high-intensity focused ultrasound transducer includes a transducer bracket 1 and a focusing piezoelectric sheet 2, the transducer bracket 1 is integrally formed, and the focusing piezoelectric sheet 2 is installed on the Inside the transducer bracket 1, a positioning column 3 is provided inside the transducer bracket 1. The positioning column 3 is provided with a positioning surface 7 and an inner ring rubber groove 4. The positioning surface 7 is used to support the focusing piezoelectric For the inner ring of the sheet 2, an inner ring glue injection port is reserved above the inner ring glue groove 4.

[0023] In this embodiment, the positioning column 3 includes an outer positioning protrusion 5 and an inner positioning protrusion 6, an inner ring rubber groove 4 is formed between the outer posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com