Three-phase separation device for water quenching product and water quenching flue gas treatment system and method

A flue gas treatment system and three-phase separation technology, applied in the field of water quenching, can solve the problems of explosion hazards, environmental protection issues, and no efficient and energy-saving treatment technology, etc., to achieve strong practicability, simple structure, and improved water quenching efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

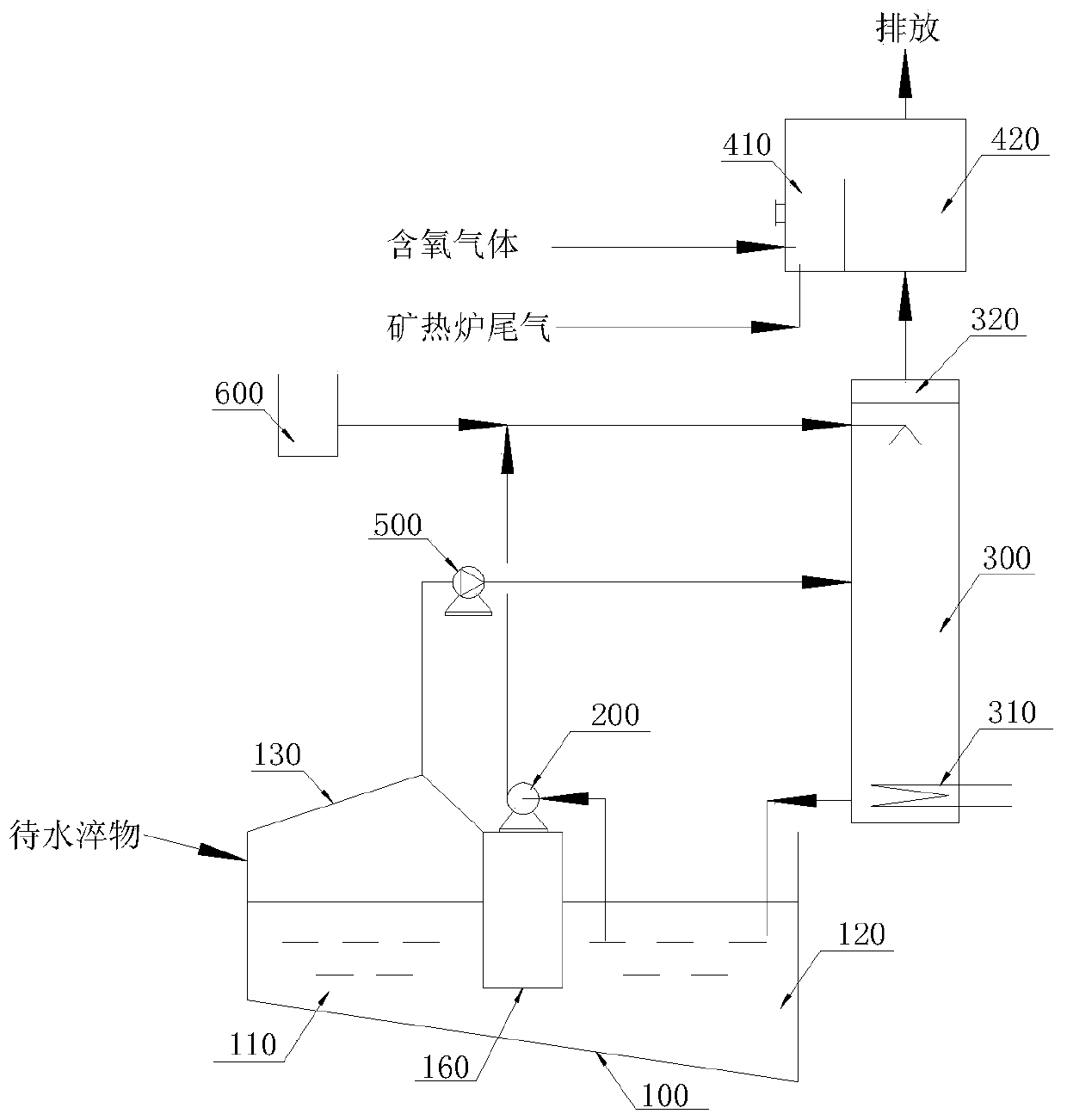

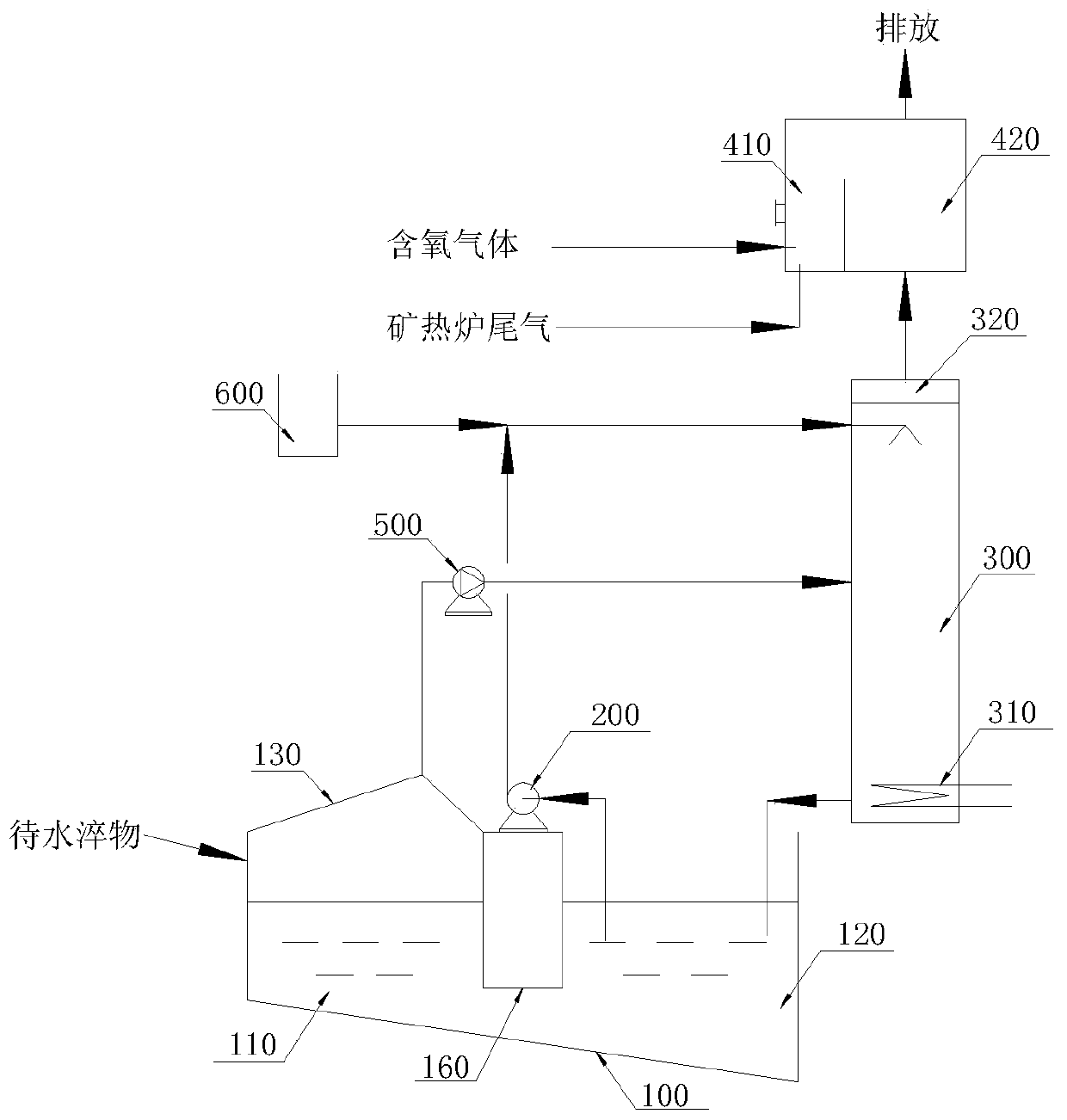

[0045] The three-phase separation device and water quenching flue gas treatment system for water quenching products in this embodiment are as follows: figure 1 shown.

[0046] Such as figure 1 As shown, the three-phase separation device for water-quenched products includes a reaction tank 100, in which a partition wall 160 extending below the liquid surface is provided, and the partition wall 160 divides the reaction tank 100 into The water quenching tank 110 and the sediment tank 120 connected by the flow channel below the partition wall 160, after the water quenching product enters the water quenching tank 110, it is converted into water quenching flue gas and water quenching slag, and the water quenching slag passes through the flow channel It flows into the sediment tank 120, and a gas collecting hood 130 for collecting the water quenching flue gas is provided above the water quenching tank 110.

[0047] The bottoms of the water quenching pool 110 and the sediment pool 1...

Embodiment 2

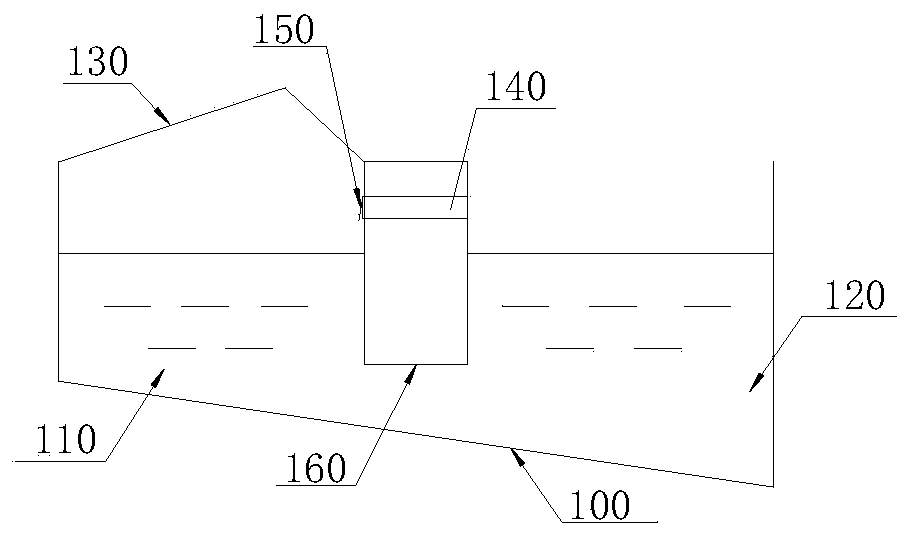

[0054] Compared with Example 1, the difference between the three-phase separation device for water-quenched products and the water-quenched flue gas treatment system of this embodiment is: figure 2 As shown, it also includes an air supply mechanism for replenishing the water quenching tank 110 when the output of the water quenching flue gas is lower than the preset value; 140 and a one-way breathing valve 150 disposed on the air hole 140 .

[0055] The method of adopting the water-quenching flue gas treatment system of embodiment 1 or embodiment 2 can treat the water-quenching flue gas in an efficient, energy-saving and environment-friendly manner, and the treated water-quenching flue gas can be discharged directly.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap