Non-taper laser cutting method

A laser cutting, no taper technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as taper problems, and achieve the effect of avoiding light blocking, no taper cutting, and increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

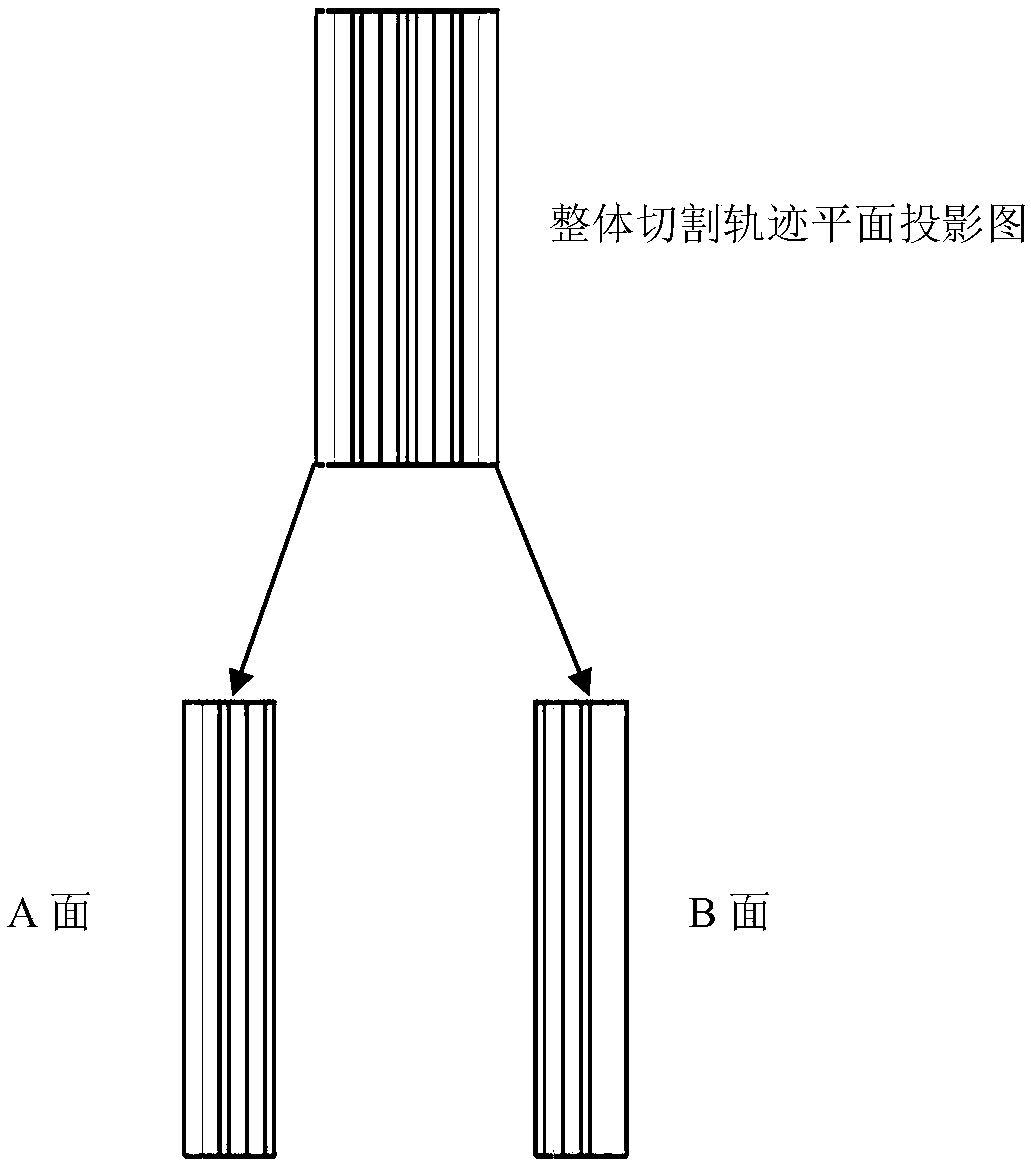

[0030] At present, ultra-fast lasers mainly use galvanometer processing to cut materials, but the galvanometer line scanning cutting method cannot solve the problem of cutting taper at one time. Aiming at the problems of damage and taper in the cutting process of airgel and other thermal structural materials with high requirements on damage and size, the invention provides a method for realizing low damage and no taper cutting by using a vibrating mirror.

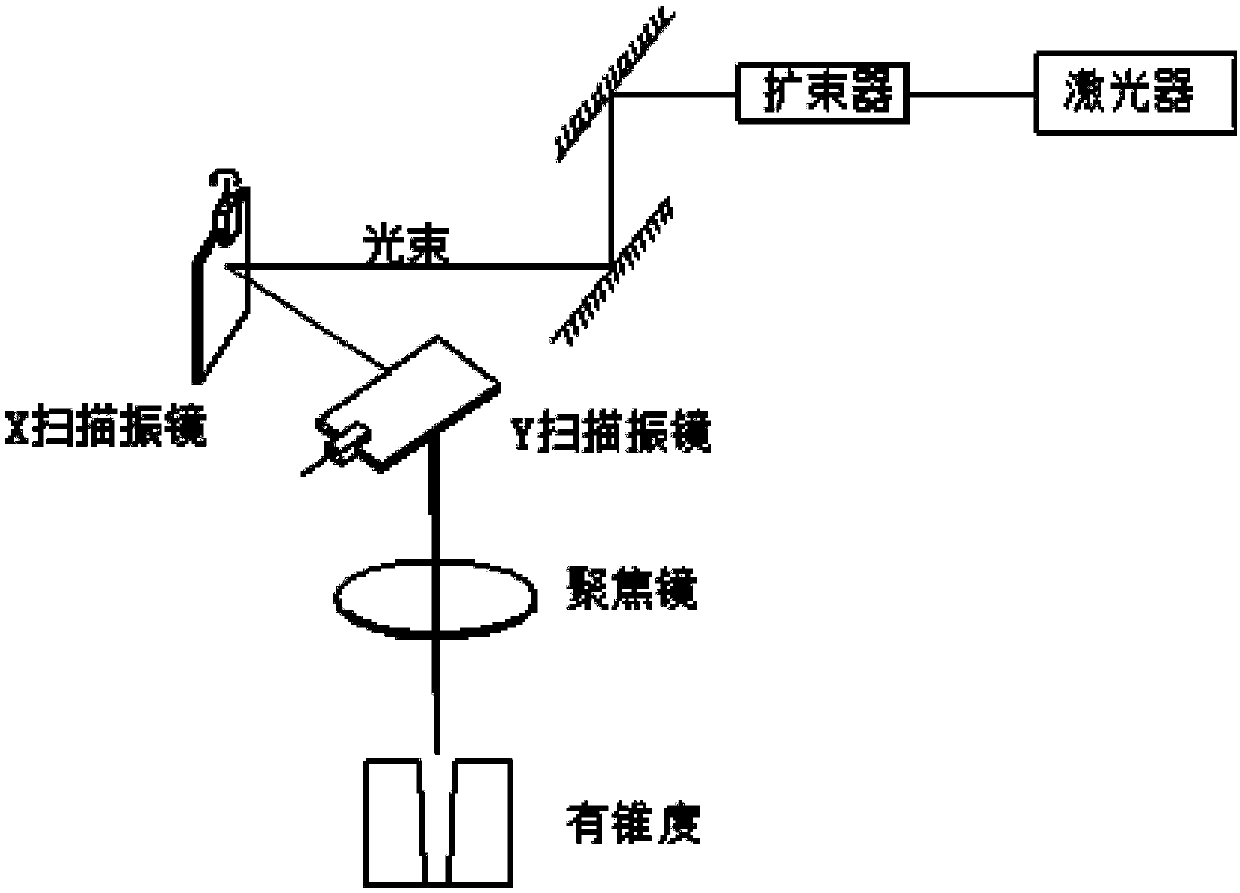

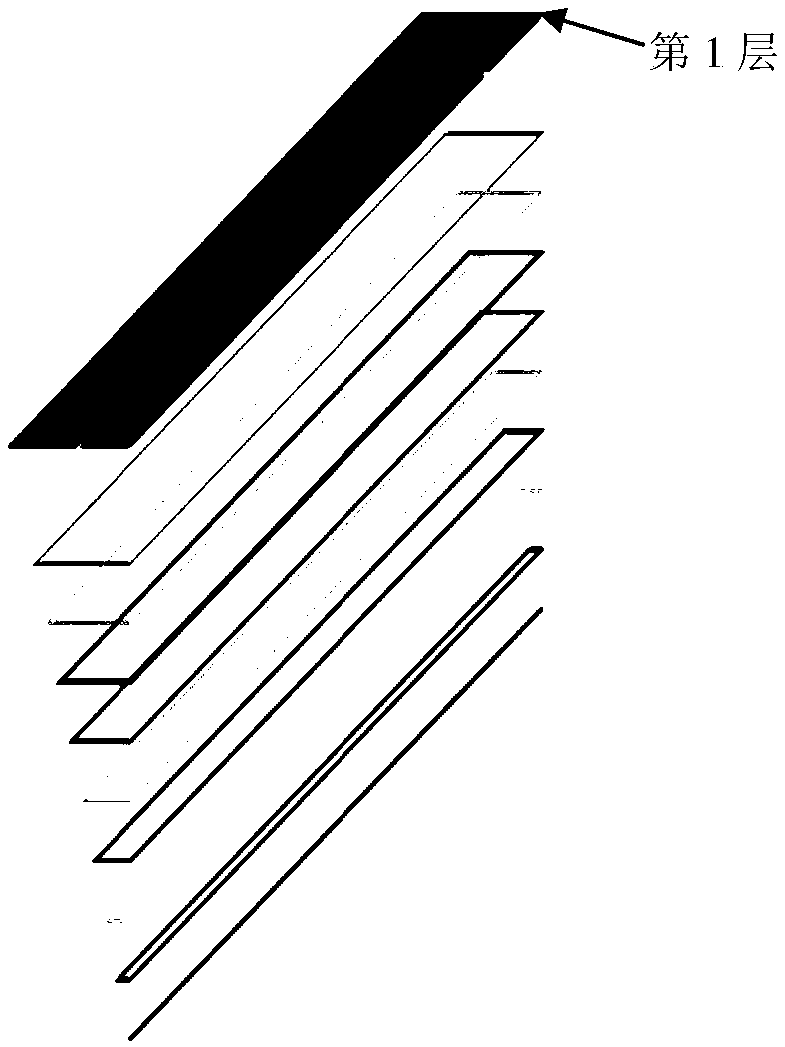

[0031] Such as figure 1 As shown, the present invention adopts the existing laser processing system, which includes a laser, a beam expander, two mirrors, a vibrating mirror system and a field mirror arranged in sequence along the optical path. The femtosecond infrared laser with a wavelength of 1030nm is selected as the laser, and the telecentric field mirror with a focal len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com