Sliding lifting device and method for arc decorative plate of building steel structure bridge

A technology of decorative panels and construction steel, applied in portable lifting devices, bridges, buildings, etc., can solve problems such as the influence of operation difficulty, limit the feasibility of bridge construction, and limit the construction environment, so as to avoid the limitation of operation difficulty and improve the application Performance and practicability, and the effect of ensuring installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

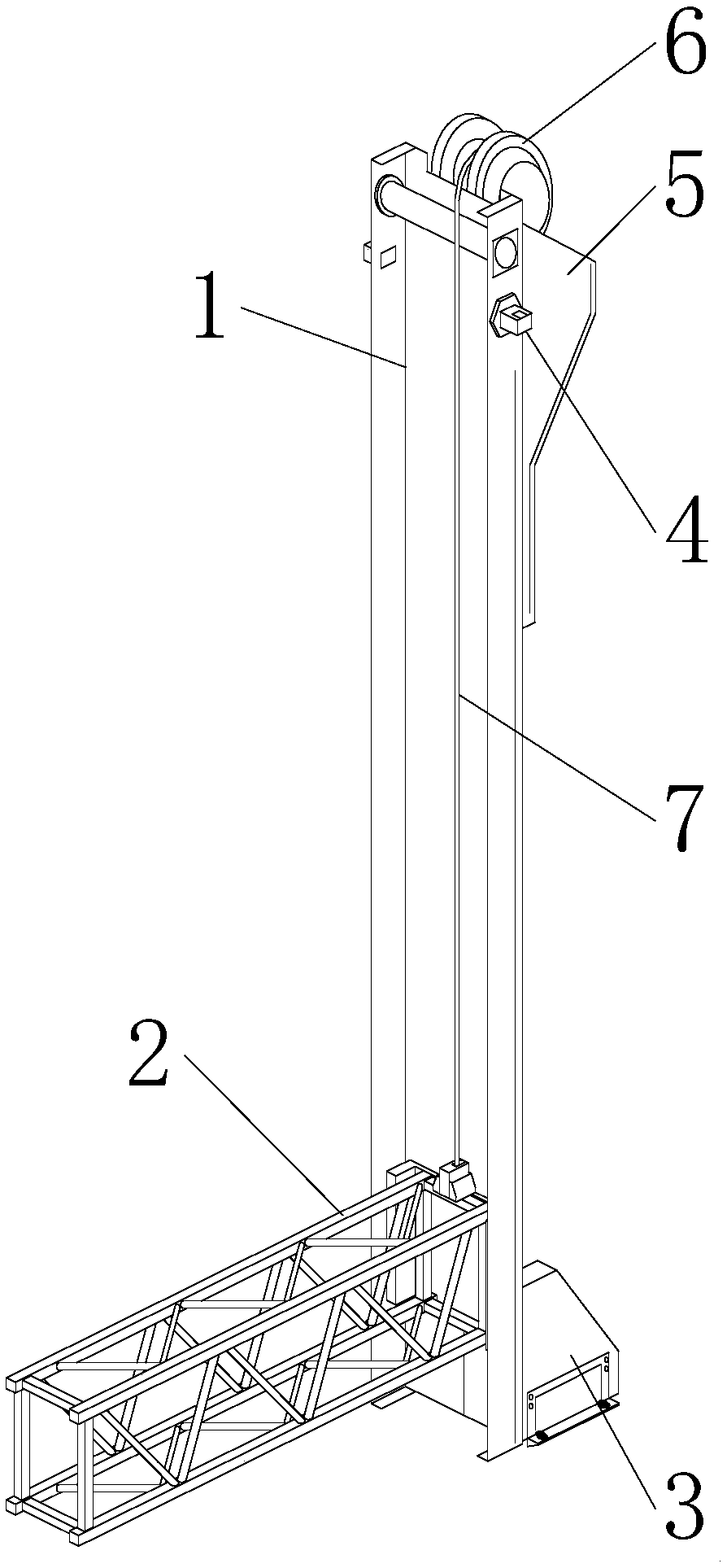

[0033] Such as figure 1 As shown, the sliding lifting device of the curved decorative plate of the steel structure bridge of the present invention includes a rail structure, a bracket structure and a sliding system.

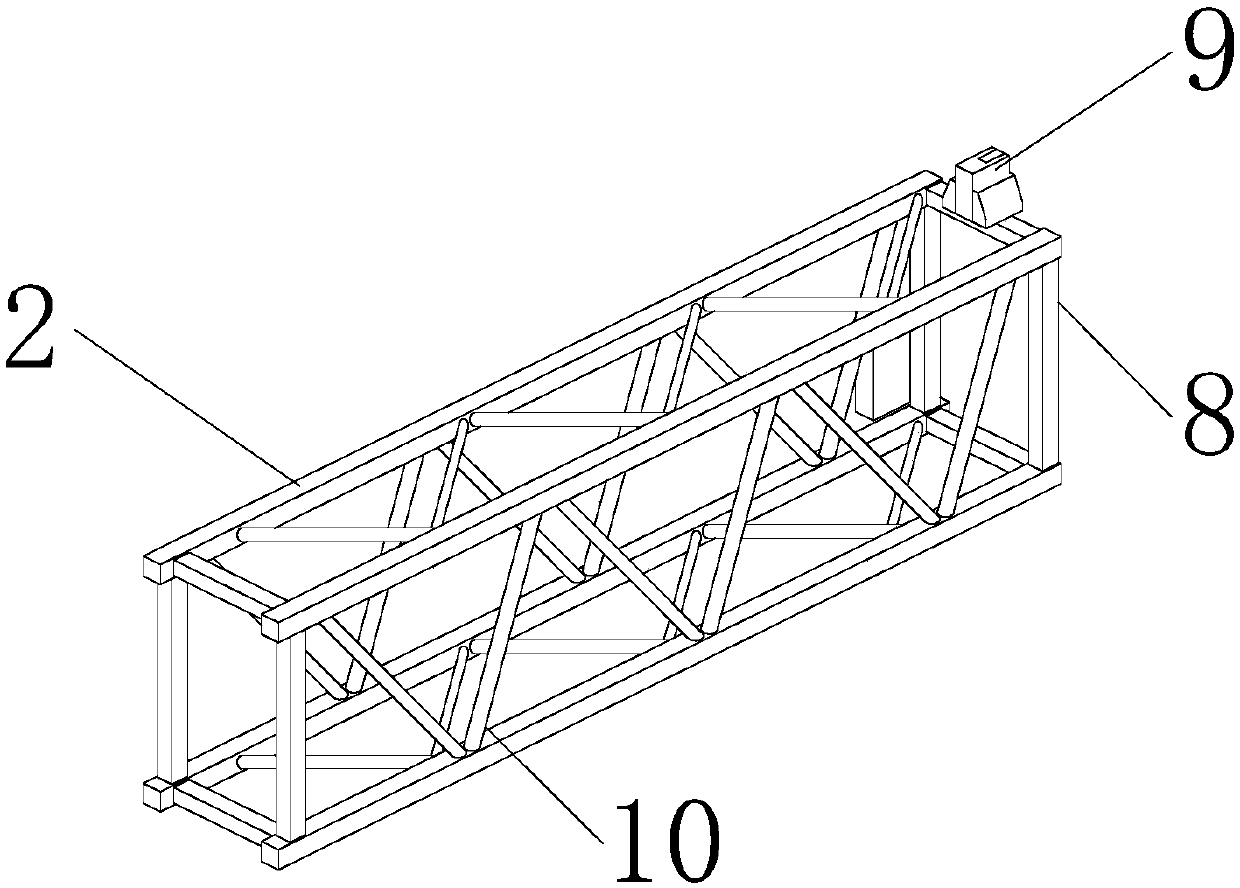

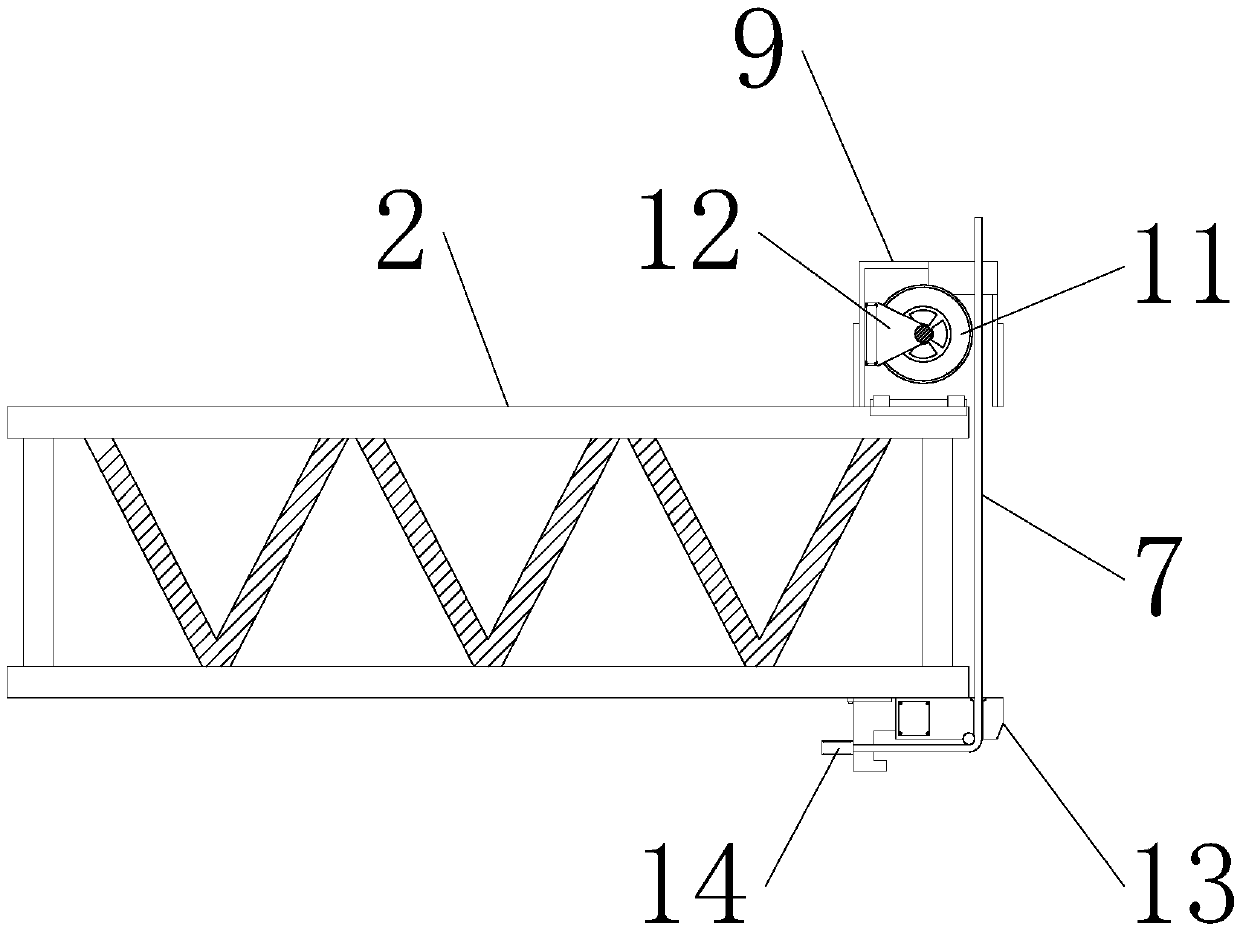

[0034] Such as Figure 1-6 As shown, the rail structure includes a main steel frame 1, a steel frame base 3, a back channel frame 5 and a sliding plate 23; Expansion bolts, the sliding plate 23 is embedded in the front of the main steel frame 1, and the front of the sliding plate 23 is symmetrically provided with two welding plates 29. The slot is provided with a twisted wire slot 28, and the slots of the twisted wire slot 28 run through the upper and lower ends of the sliding plate 23; the steel frame base 3 is welded to the bottom end of the main steel frame 1 back, and the steel frame base 3 is composed of a thick steel frame pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com