A kind of preparation method of battery grade iron phosphate with low sulfur content

A low-sulfur content, iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of increasing the pressure of environmental protection wastewater treatment, high sulfur content of iron phosphate finished products, unfavorable large-scale promotion, etc., to achieve Solve the problem that the sulfur content is difficult to control, reduce the amount of washing water, and solve the effect of high sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

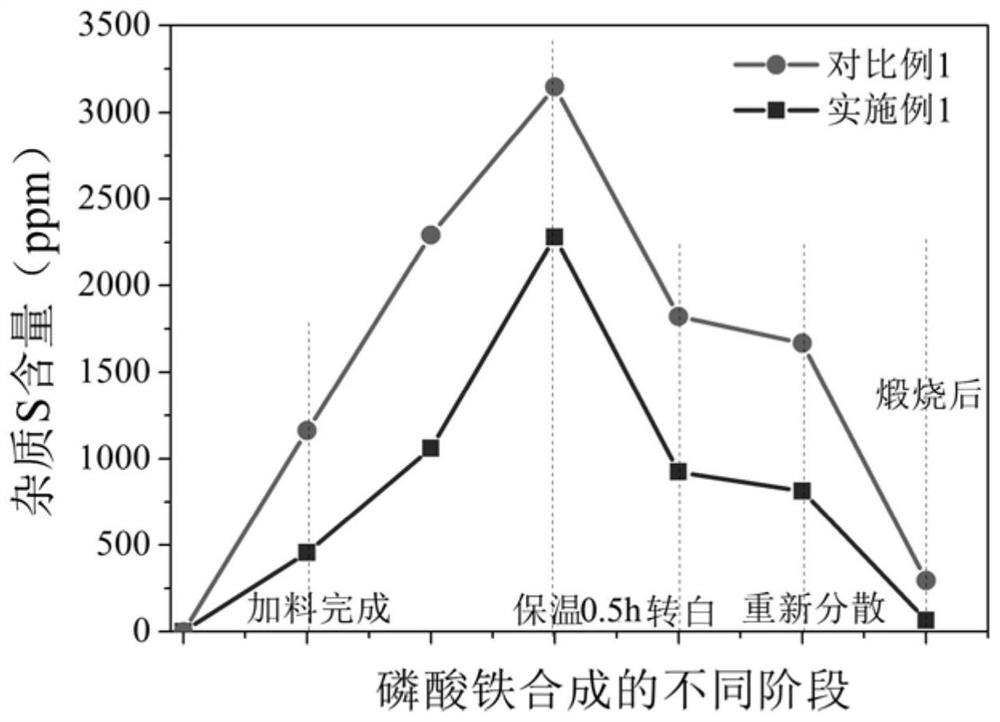

Embodiment 1

[0026] Embodiment 1 of the present invention is: a method for preparing low-sulfur battery-grade iron phosphate, comprising the following steps:

[0027] (1) Configuration of the reaction raw material solution:

[0028] According to the molar ratio of hydrogen peroxide and ferrous sulfate is 0.5:1, hydrogen peroxide solution and ferrous sulfate solution are mixed, carry out oxidation reaction, obtain ferric sulfate raw material liquid, the mass concentration of iron element in ferric sulfate raw material liquid is 56g / L; Phosphate raw material liquid, the mass concentration of phosphorus element in the phosphate raw material liquid is 31g / L.

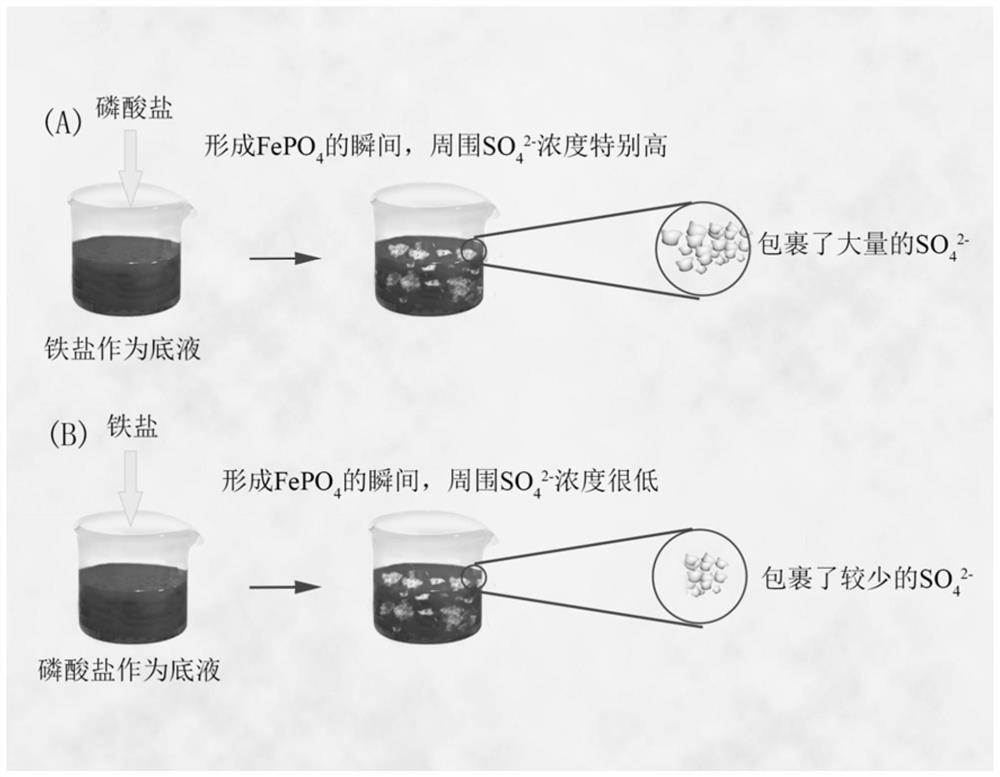

[0029] (2) Carrying out of synthetic reaction:

[0030] According to the molar ratio of phosphorus in the phosphate raw material liquid and iron in the ferric sulfate raw material liquid is 1.25:1, add the ferric sulfate raw material liquid to the phosphate raw material liquid, the feeding time is 100min, the speed is 40mL / min, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com