Wine distillation cooling tower

A technology for cooling towers and wine, applied in the field of machinery, can solve the problems of high labor intensity, easy burning of raw materials, shortening the service life of wine pots, etc., and achieve the effects of high practical value, high stability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

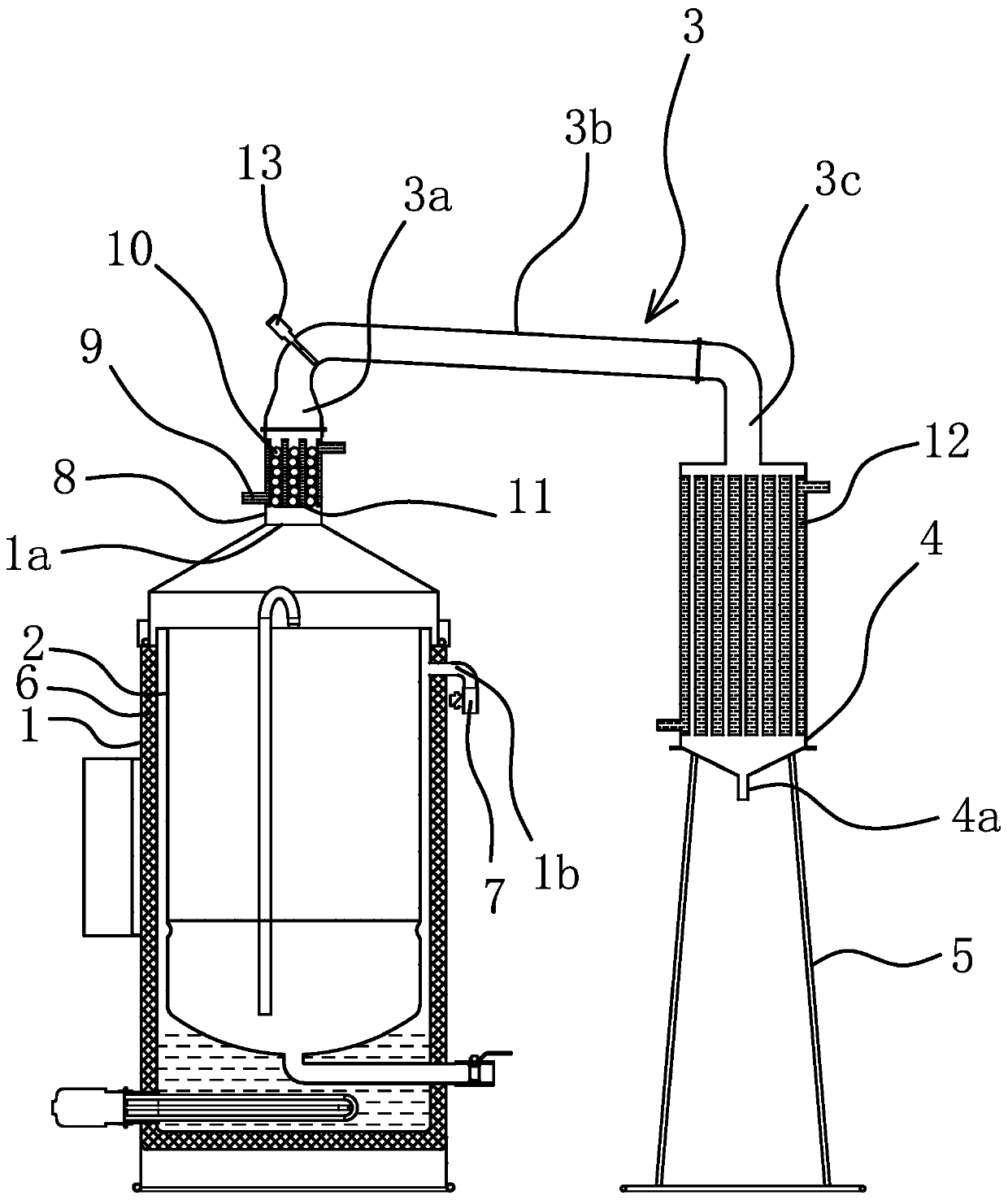

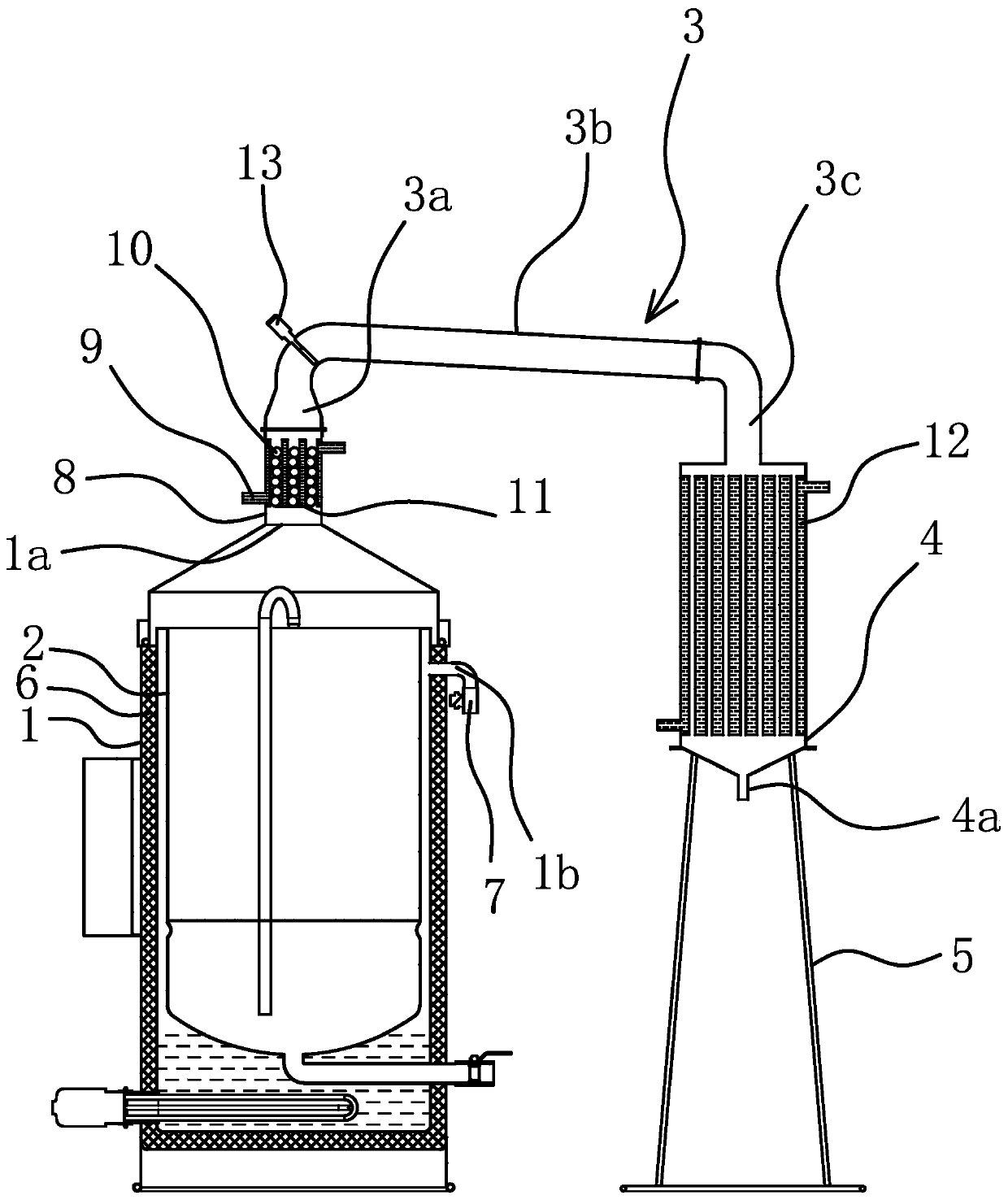

[0033] like figure 1 As shown, the wine distillation cooling tower includes a body with a cavity inside, and the upper end of the body is an outlet 1a communicating with the inner cavity. The body includes a cylindrical outer cylinder 1 and an inner cylinder 2. The outer cylinder 1 is sleeved on the inner cylinder 2 with a gap between them. The bottom of the outer cylinder 1 is connected to the inner cylinder 2. There is a storage chamber between the bottoms for storing the heating medium, and the storage chamber has a heating element for heating the heating medium in it, and also includes the first condensation mechanism, the second condensation mechanism, the connecting pipe 3, the wine outlet cylinder 4 and the bracket 5. The first condensation mechanism is connected to the outlet 1a, the bracket 5 is located on the side of the body, the wine outlet cylinder 4 is fixedly connected to the bracket 5, the condensation mechanism two is located in the wine outlet cylinder 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com