A composite spinning melt-blown non-woven fabric with antibacterial function and its preparation method and application

A technology of melt-blown non-woven fabric and composite spinning, which is applied in the manufacture of rayon, conjugated synthetic polymer rayon, non-woven fabric, etc. Small scope, complex chemical oxidation modification methods, etc., to achieve stable and long-lasting antibacterial performance, improve load uniformity and stability, and high load uniformity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a composite spun meltblown nonwoven fabric having an antibacterial function, the fibers employed, the core layer is polypropylene, and the cortical component is 2% silver-modified nanometers from mass percent. Zinc oxide composite, 40% mercapto-modified polypropylene nitrile and 58% polypropylene composition.

[0039]The method of preparing the mercapto-modified polypropylene nitrile is: Take 1 g of polyacrylonitrile immersed in methanol solution containing 1 g 4-amino-1- (3-mercapto-propyl) -pyridiniklofluorophosphate ionic liquid. NaOH retained the reaction system to a weak alkaline (pH 7.5-9.0), reacted at 130 ° C; after the reaction was completed, washed out of distilled water to neutral; the preliminary product was soaked with 0.1 mol / l HCI solution. 2H, after removal, washed with distilled water to neutral, and dried to constant weight at 60 ° C, i.e., the mercapto-modified polyacrylonitrile slices.

[0040] The method of preparing the silve...

Embodiment 2-5

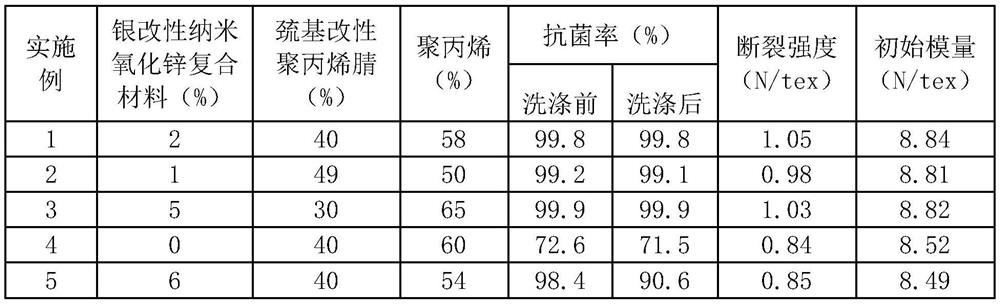

[0048] Example 2-5 provides a composite spinning spray nonwoven fabric having an antibacterial function, and is different from the first embodiment, and the mass percentage of each component in the cortex component is changed. It will not be described herein, and the specific experimental parameters and performance test results are shown in the table below.

[0049]

[0050] As can be seen from the above table, the composite spinning spray nonwoven fabric made by the present invention has better antimicrobial properties, washable properties and mechanical strength, and the non-woven fabric made under Example 1 is optimal. . Comparative Examples 1 to 3 As in Example 4, it is understood that the present invention passes through a sulfhydryl group 4-amino-1- (3-mercapto-propyl) -pyridine hexafluorophosphate ion liquid quaternary ammonium salt polymer antibacterial agent Synergistic effects of silver-modified nano-zinc oxide inorganic antibacterial agents, the resulting nonwoven fab...

Embodiment 6-12

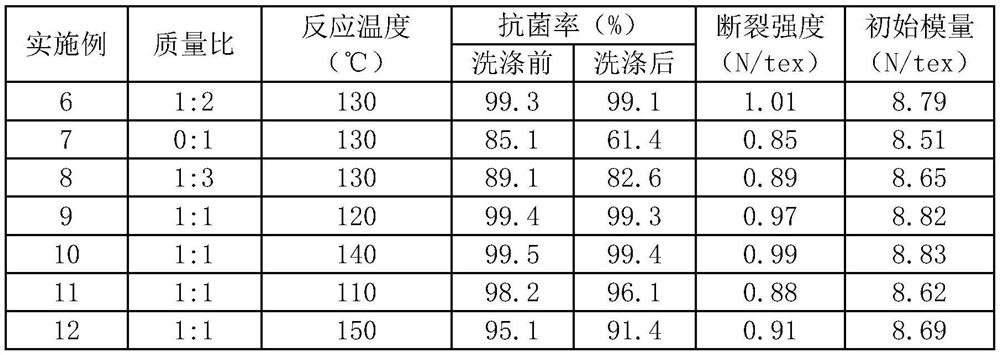

[0052] Example 6-12 provides a composite spinning meltblown nonwoven fabric having an antibacterial function, and is different from that of Example 1, in that the process of changing the grafting modification reaction of the agglomerate modified polyacrylonitrile. - Amino-1- (3-mercapto-propyl) - pyridyl hexafluorophosphate ion liquid and the mass ratio of the polypropylene nitrile and / or grafting reaction temperature, the other operations are the same, and will not be described again, specific experimental conditions The parameters and performance test results are shown in the table below.

[0053]

[0054] According to the above table, it is known that the quality of 4-amino-1- (3-mercapto-propyl) -pyridinonitrile and polypropylene ionic nitrile is changed during the graft modified reaction of the aging-modified polyacrylonitrile graft modified reaction. The ratio of composite spun molten nonwoven fabric has better antimicrobial properties, washable performance and mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com