Floating unit plate

A unit board and floating board technology, applied in the field of rail transit, can solve the problems of construction space and transportation and hoisting restrictions, poor driving safety, and high maintenance costs, reducing maintenance times and maintenance difficulties, improving service life, and driving safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

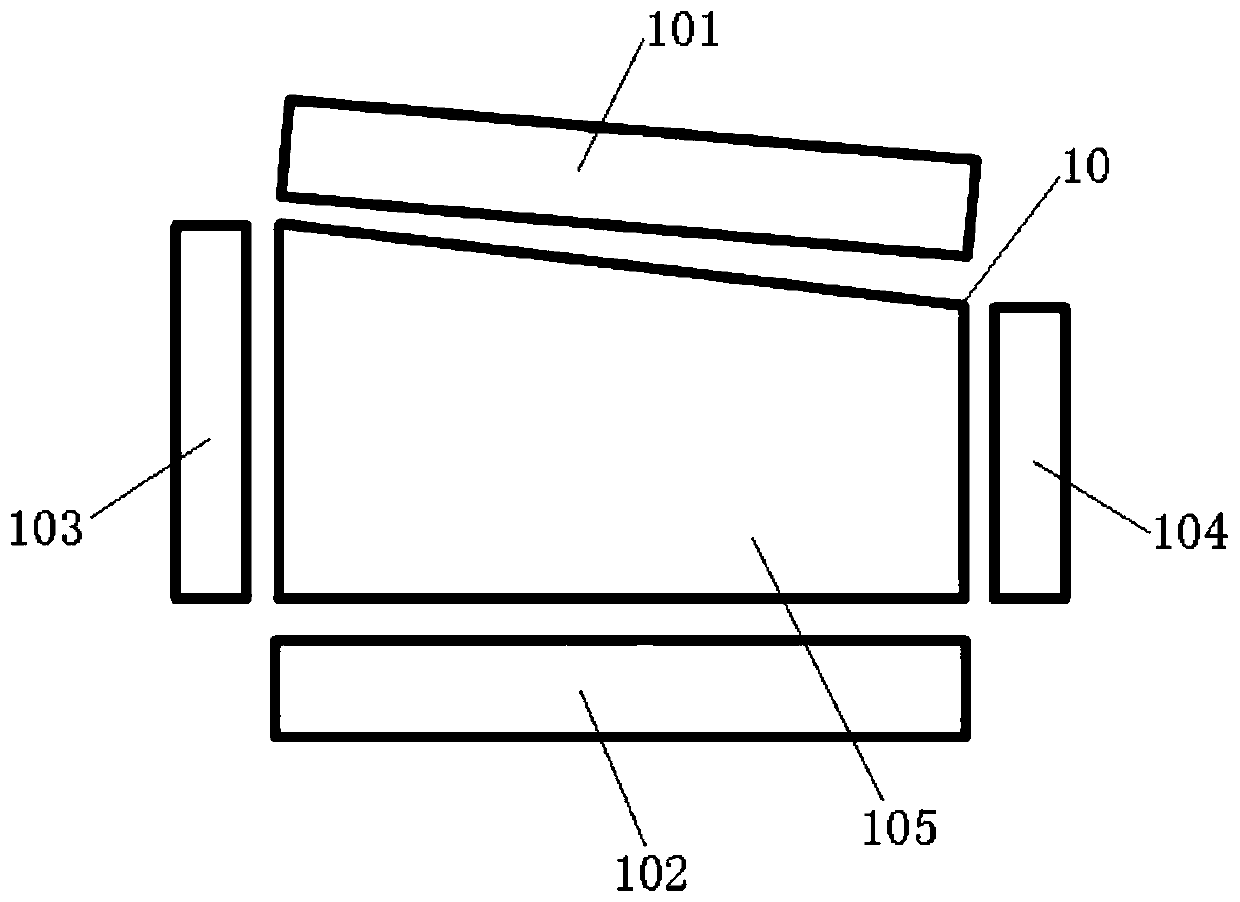

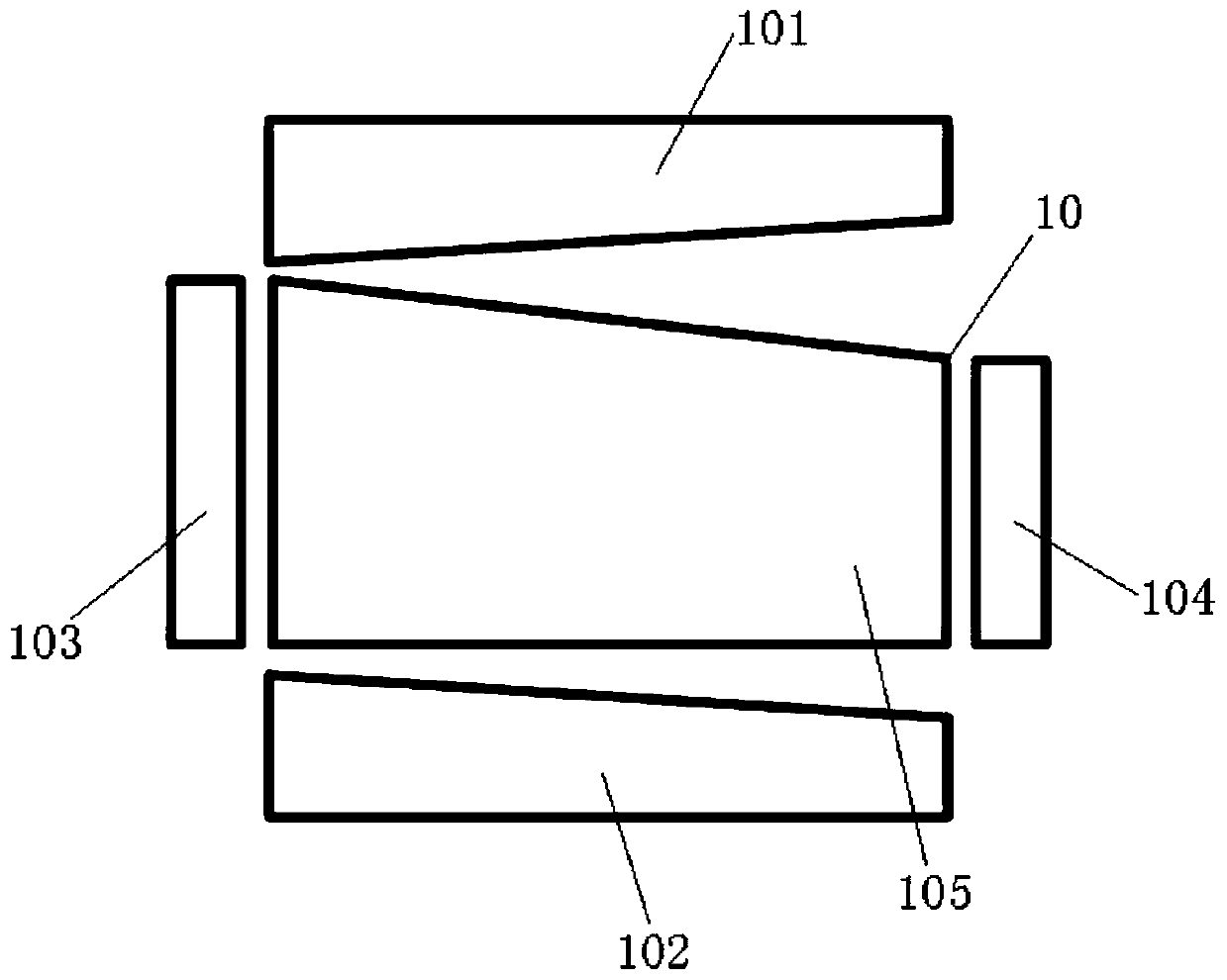

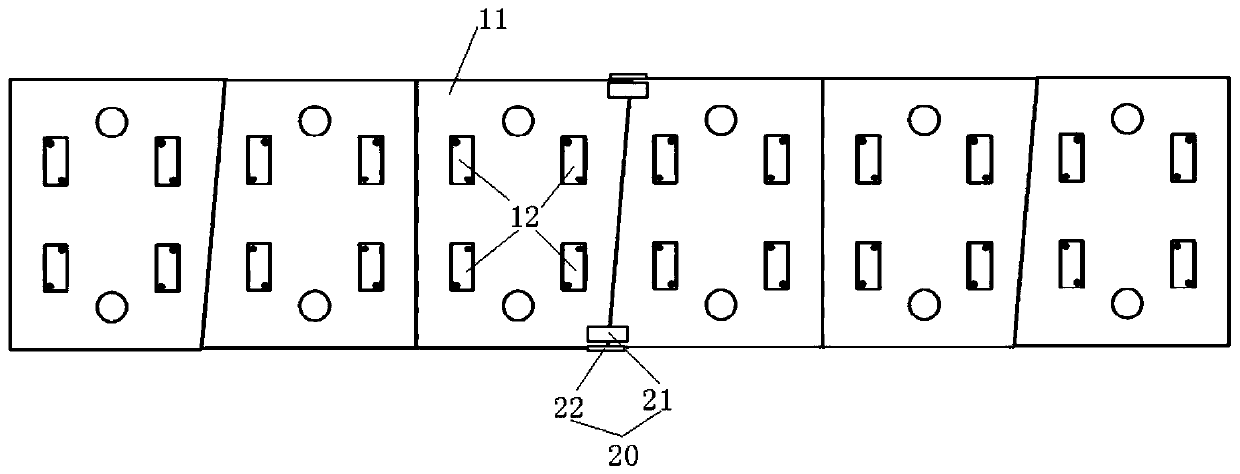

[0035] refer to Figure 1-Figure 12, a preferred embodiment of the present invention provides a floating unit plate, including: a plurality of floating plate unit blocks 10 and a connecting assembly 20, the plurality of floating plate unit blocks 10 are arranged in sequence along the extending direction of the track line and are spliced and connected, The connection assembly 20 is used for connecting multiple floating plate unit blocks 10 to form a floating unit plate. The floating plate unit block 10 is provided with a first splicing surface 101 and a second splicing surface 102 arranged oppositely, the first splicing surface 101 and the second splicing surface 102 are arranged along the width direction of the floating unit plate, and the first splicing surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com