Open-close type boat house

An opening-and-closing, boathouse technology, which is applied to buildings where cars are parked, arched structures, dome-roof structures, etc. cracks and other problems, to achieve the effect of shortening the flight time, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

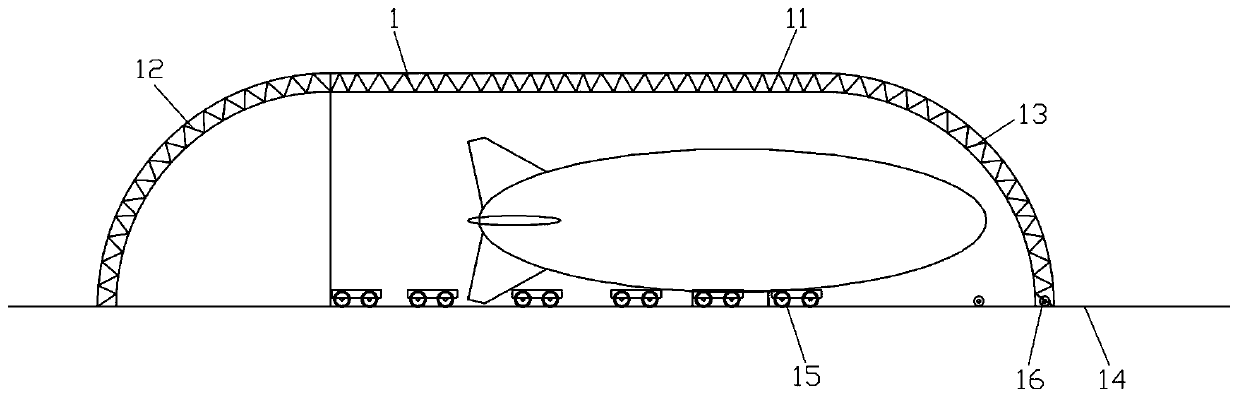

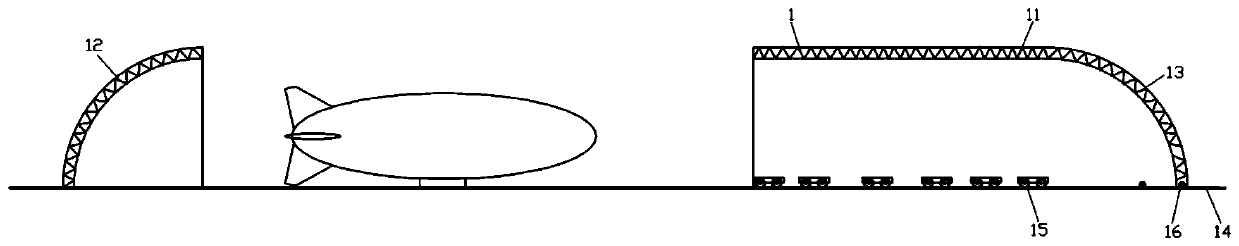

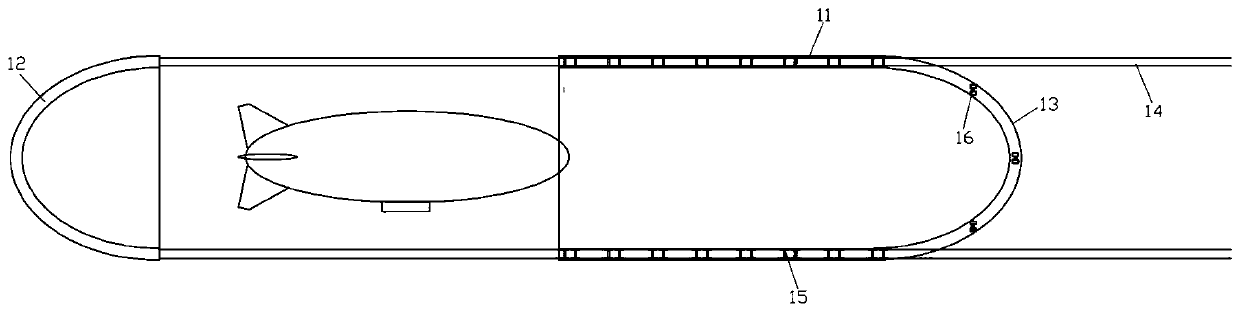

[0038] Embodiment 1: This embodiment details the structure of a translational opening and closing type boat garage 1, see Figure 1-3 Shown:

[0039] The translational opening and closing type boat garage 1 includes a front dome 11 and a rear dome 12, at least one of the front dome 11 and the rear dome 12 is a movable dome. In this embodiment, the front dome 11 is connected to the foundation through a mobile load-bearing mechanism , the rear dome 12 is fixedly connected to the foundation, the rear dome 12 is directly a 1 / 4 ellipsoidal dome head 13 structure, and the front end of the front dome 11 is also a 1 / 4 ellipsoidal dome head 13 structure. The front dome 11 and the rear dome 12 are composed of internal metal trusses or net frames and external protective skins. The front dome 11 and the rear dome 12 move oppositely and horizontally to realize closing to form an integral boathouse, and the front dome 11 and the rear dome 12 move back to realize the opening of the boathous...

Embodiment 2

[0046] Embodiment 2: This embodiment details the structure of a split-flap openable boat garage 2, see Figure 4-5 Shown:

[0047] The split-flap openable boathouse 2 includes a left dome 21, a right dome 22 and a self-driven push rod 24. The trusses of the left dome 21 and the right dome 22 in the split-petal openable boathouse 2 are composed of multi-section trusses in sequence. Each segment of the truss is connected to the foundation 23 through a hinge I26 and at least one set of self-driven push rods 24 is configured. Each of the left dome 21 and the right dome 22 realizes the angle change through the corresponding self-driven push rod 24, and the left dome 21 and the right dome 22 are both through the respective corresponding self-driven push rod 24 and the hinge anchored on the foundation 23 I26 constrains the angle of the dome, and changes the expansion and contraction of the self-driven push rod 24 to change the opening and closing angle of the dome. The self-driven ...

Embodiment 3

[0051] Embodiment 3: In the above-mentioned embodiment 1 and embodiment 2, the rainproof structure 3, the sealing buffer structure 5 and the locking structure at the joint end of the two domes in the translational opening and closing type boathouse 1 or the split opening and closing type boathouse 2 The specific structure of organization 4 is as follows: Image 6 Shown:

[0052] The combined ends of the two domes when the garage is closed include end plates I31 and end plates II32 respectively arranged on the two domes. Wherein, the rainproof structure 3 includes a rainproof cover 33 arranged on the outer edge of the end plate I31, the bent bottom of one side of the rainproof cover 33 is fixedly connected with the outer side of the end plate I31, and the other part of the rainproof cover 33 One side is bent downward to form a drip edge 34 covering the end plate II 32 , and the outer edge of the end plate II 32 protrudes from the skin to form a water-proof edge, which can bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com