Temperature limiter mounting structure and heater

A technology of installation structure and temperature limiter, which is applied in heating methods, lighting and heating equipment, household heating, etc., can solve the problems of complex assembly process and high assembly cost of temperature limiter, and achieve simple structure, high assembly efficiency, and easy assembly. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

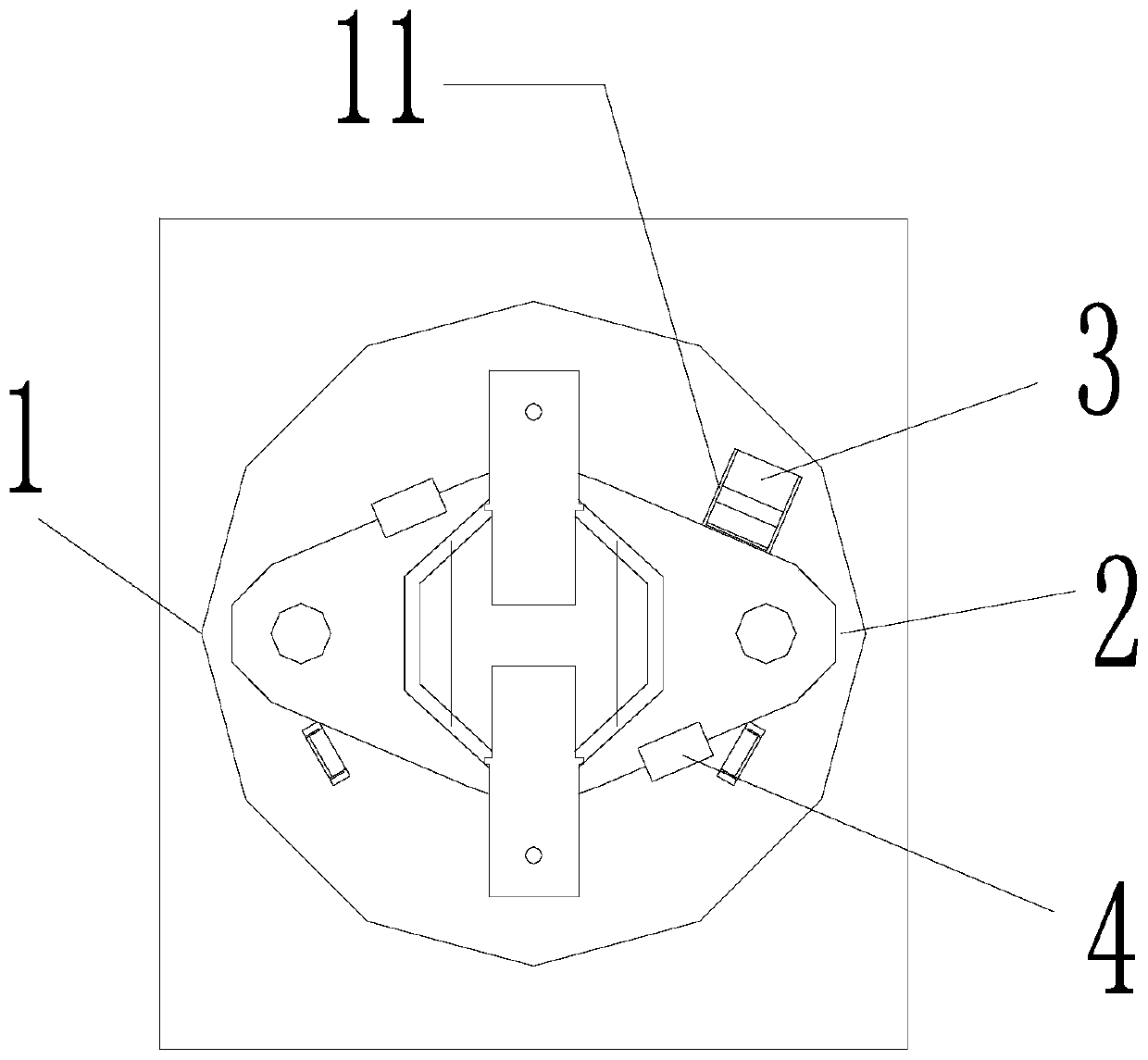

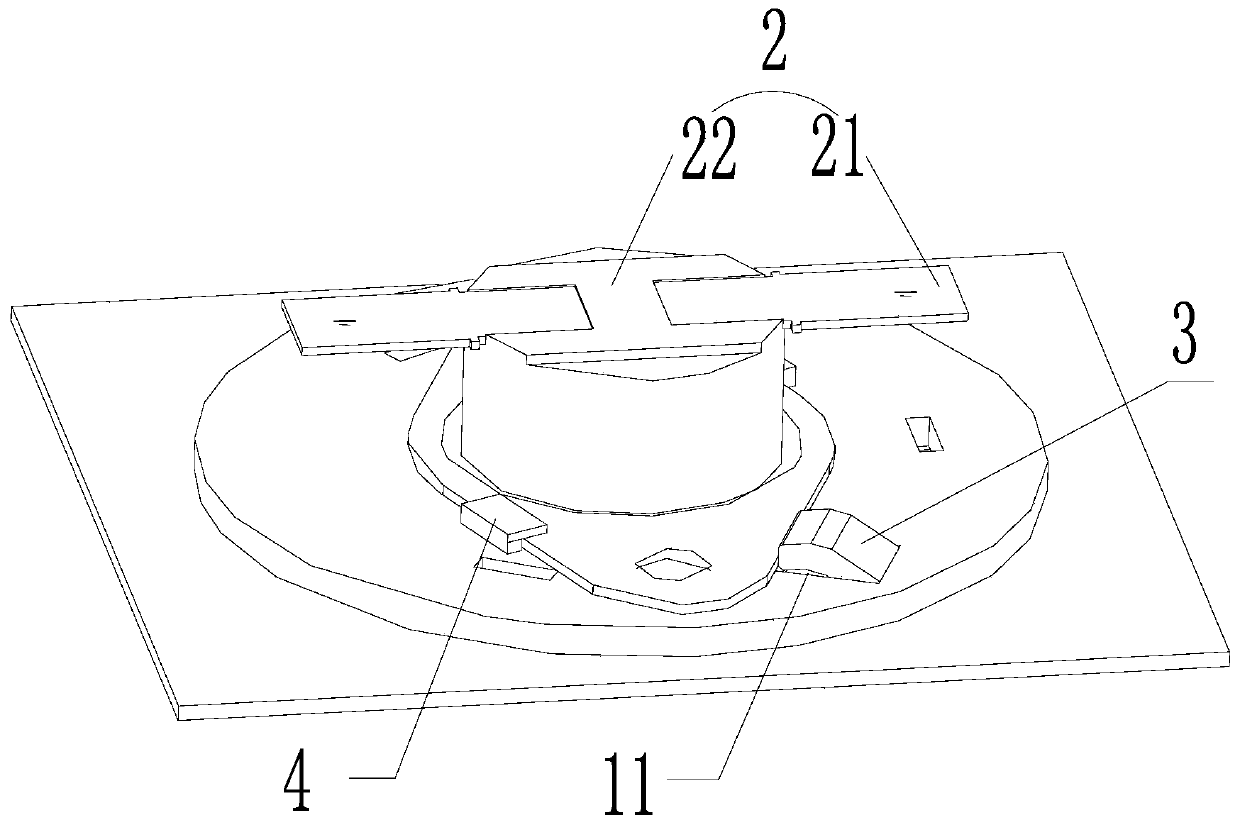

[0042] This embodiment provides a temperature limiter installation structure, such as figure 1 , figure 2 and image 3 As shown, it includes: a connection chuck 1; a temperature limiter 2, which is rotatably arranged on the connection chuck 1; at least one snap button 3, which is arranged behind the movement path of the temperature limiter 2 and connected to the On the connection chuck 1, the top end of the snap button 3 extends toward the temperature limiter 2, and the connection chuck 1 is provided with a notch 11 suitable for the insertion of the snap button 3; two limit positions A plate 4 is provided with an inlet suitable for the connection chuck 1 to enter, and the limiting plate 4 is arranged in front of the movement path of the temperature limiter 2 .

[0043] In this example, if figure 2 As shown, the limiter includes a main body 22 and a connecting plate 21 connected to the main body 22, the main body 22 is arranged at the center of the connecting plate 21, the...

Embodiment 2

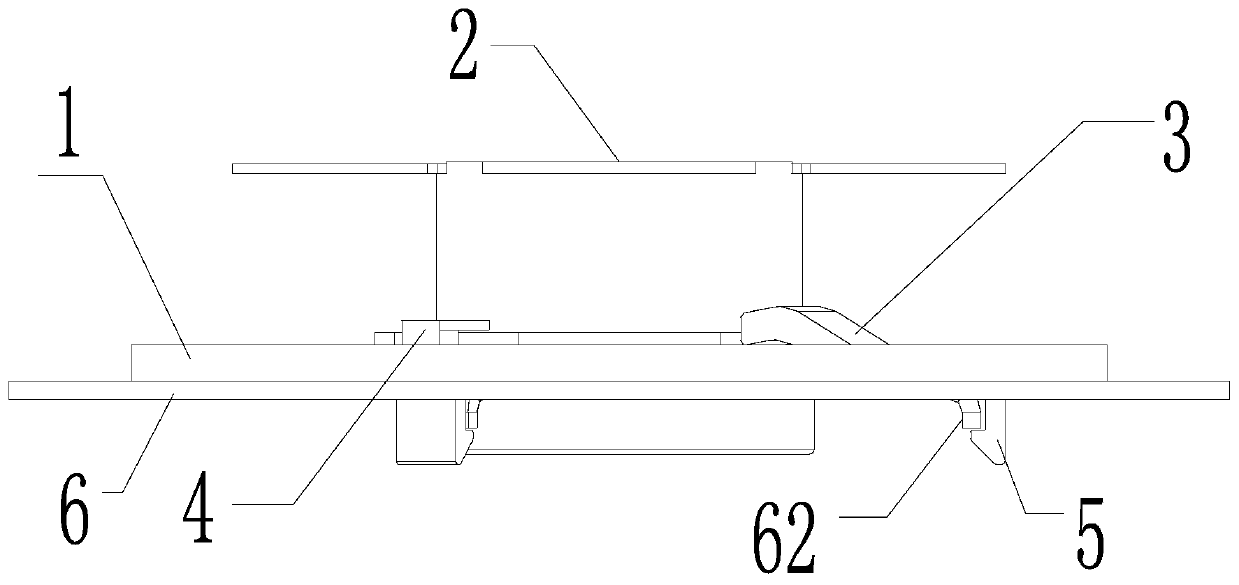

[0056] This embodiment provides a heater, including: a housing 6; the installation structure of the temperature limiter provided in Embodiment 1, the connection chuck 1 of the installation structure of the temperature limiter 2 is detachably arranged on the housing 6 .

[0057] Through the combination of the limiting plate 4 and the spring buckle 3, it is possible to avoid separately setting screws to fix the temperature limiter 2, saving materials and reducing manufacturing costs. At the same time, the assembly process of the temperature limiter 2 is simple and the assembly efficiency is high, which helps to reduce the labor cost in the production process of the heater. In addition, through the integrated assembly structure, the temperature limiter 2 can be directly installed on the heater, and the structure is simple.

[0058] In the heater provided in this embodiment, the casing 6 is provided with a through hole 61 , and the buckle 5 of the connection chuck 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com