Slag inlet pipe provided with slag leaking prevention protection device and slag leaking prevention protection method of slag inlet pipe

A technology of protection device and slag feeding pipe, which is applied in the field of industrial safety, can solve problems such as wear, cracking, leakage of red slag, scald workers, and inability to isolate, so as to avoid burns, ensure production efficiency, and avoid fire safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

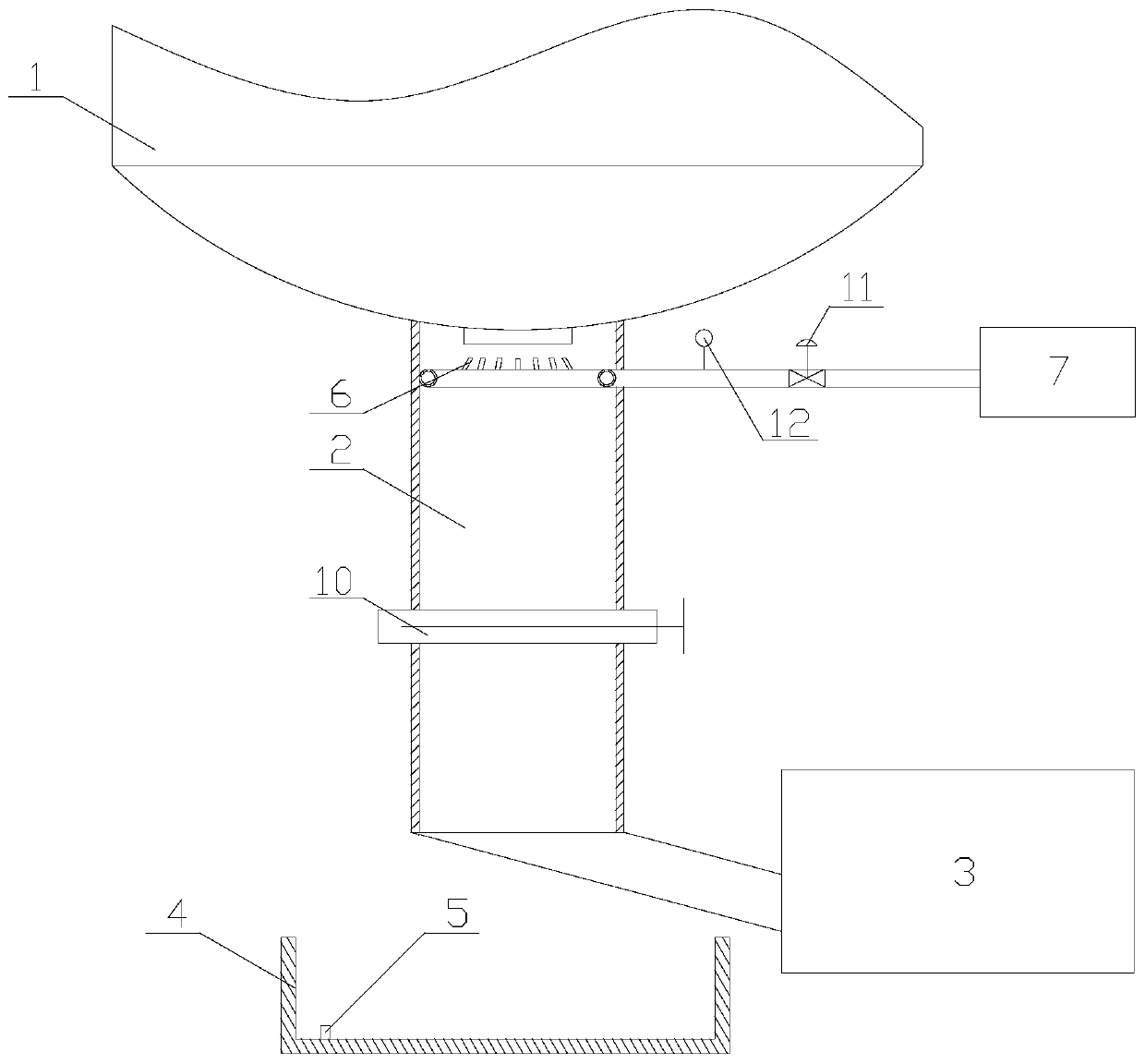

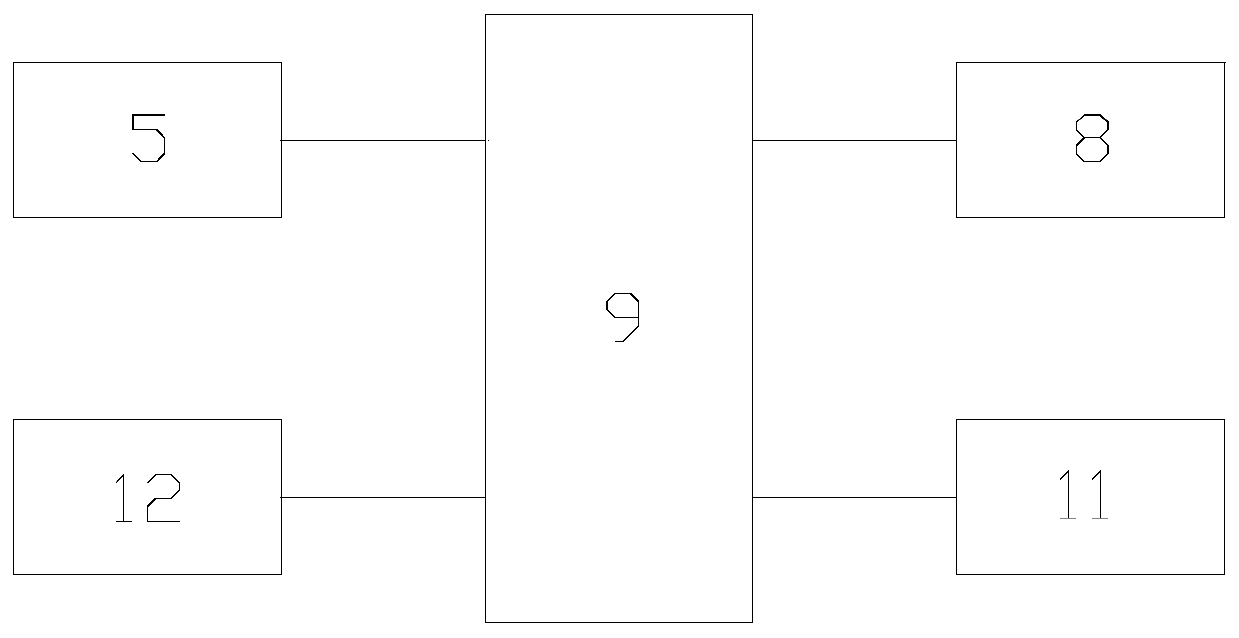

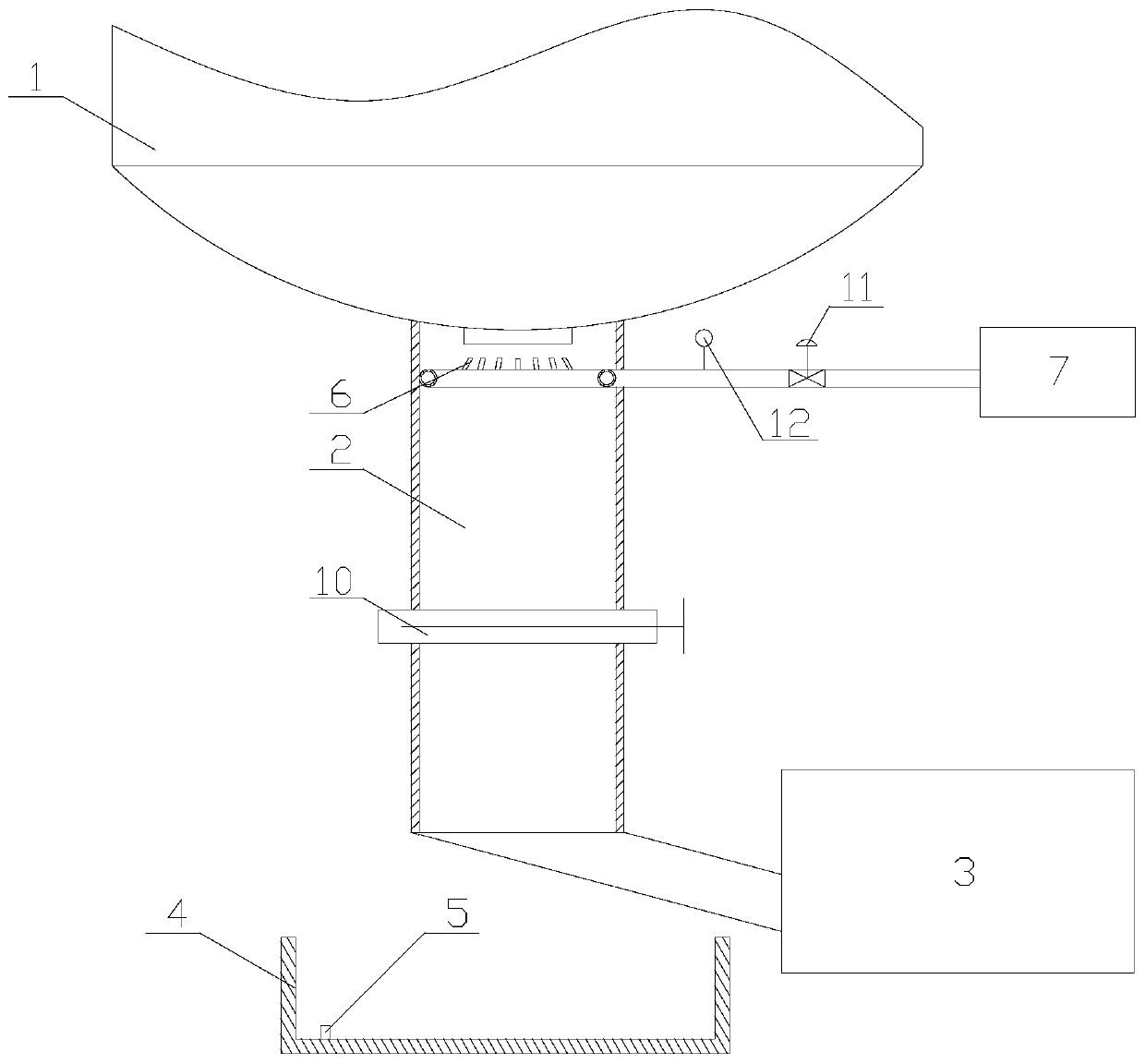

[0016] Embodiment 1: as Figure 1-2 As shown, a slag feeding pipe provided with an anti-leakage slag protection device includes a fluidized bed boiler 1 and a slag cooler 3 connected through a slag feeding pipe 2, and a sliding door 10 arranged on the slag feeding pipe 2 , a slag receiving tank 4, a temperature sensor 5, an air nozzle 6, a compressed air source 7, an alarm device 8 and a controller 9; a slag receiving tank 4 is arranged below the slag feeding pipe 2, and a temperature Sensor 5; on the inner wall of the slag inlet pipe 2 above the sliding door 10, several air nozzles 6 are fixed along the circumferential direction of the slag inlet pipe 2, and the air outlets of the air nozzles 6 are arranged toward the slag discharge port of the fluidized bed boiler 1; The air nozzle 6 is connected with the compressed air source 7 through a pipeline; the pipeline connecting the air nozzle 6 and the compressed air source 7 is provided with a pressure sensor 12 and a solenoid va...

Embodiment 2

[0017] Embodiment 2: Utilize the anti-leakage slag protection method of the slag inlet pipe described in embodiment 1, which includes:

[0018] The first temperature setting value of 75°C and the second temperature setting value of 100°C are preset in the controller 9, because when the slag feeding pipe 2 leaks, the leaked ash will fall into the slag receiving tank 4, High-temperature ash will cause the temperature in the slag receiving tank 4 to rise, so the temperature sensor 5 will monitor the temperature value in the slag receiving tank 4, and transmit the monitored temperature value to the controller 9, and the controller 9 will make a logical judgment. Judging whether the measured temperature value reaches the first temperature setting value or the second temperature setting value; when the detected temperature value reaches the first temperature setting value, it indicates that there is a slight slag leakage in the slag feeding pipe 2, so only The alarm device 8 is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com