Gas stove

A gas stove and stove body technology, applied in the field of stoves, can solve the problems of cumbersome operation, easy to stick to oil stains, affecting the wiping efficiency, etc., and achieve the effects of convenient operation, convenient operation, easy extraction or insertion and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

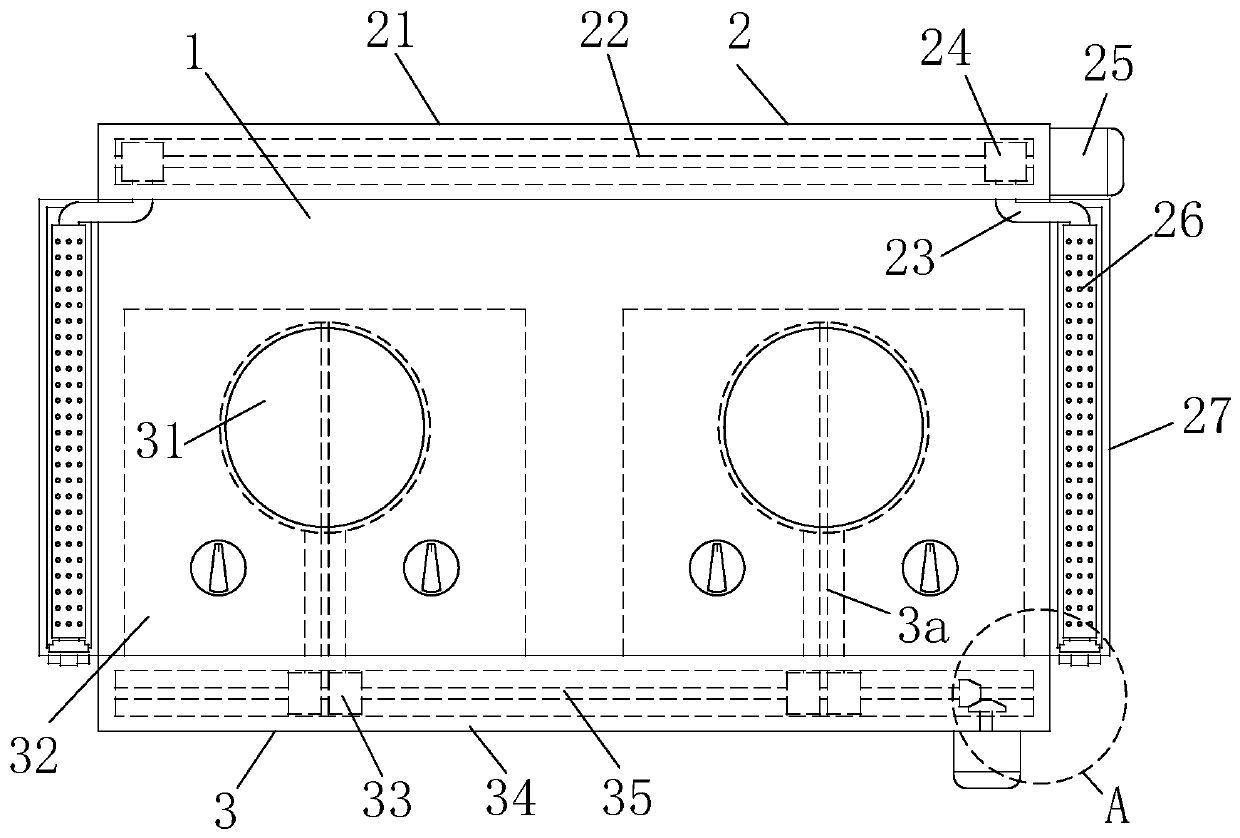

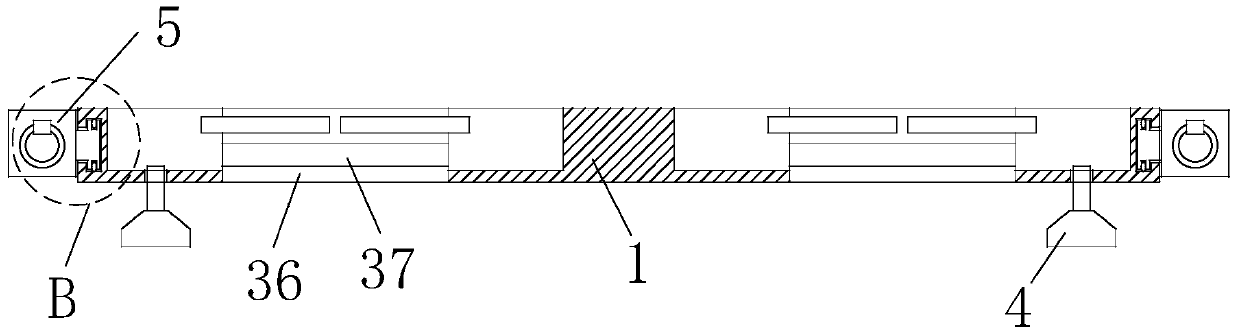

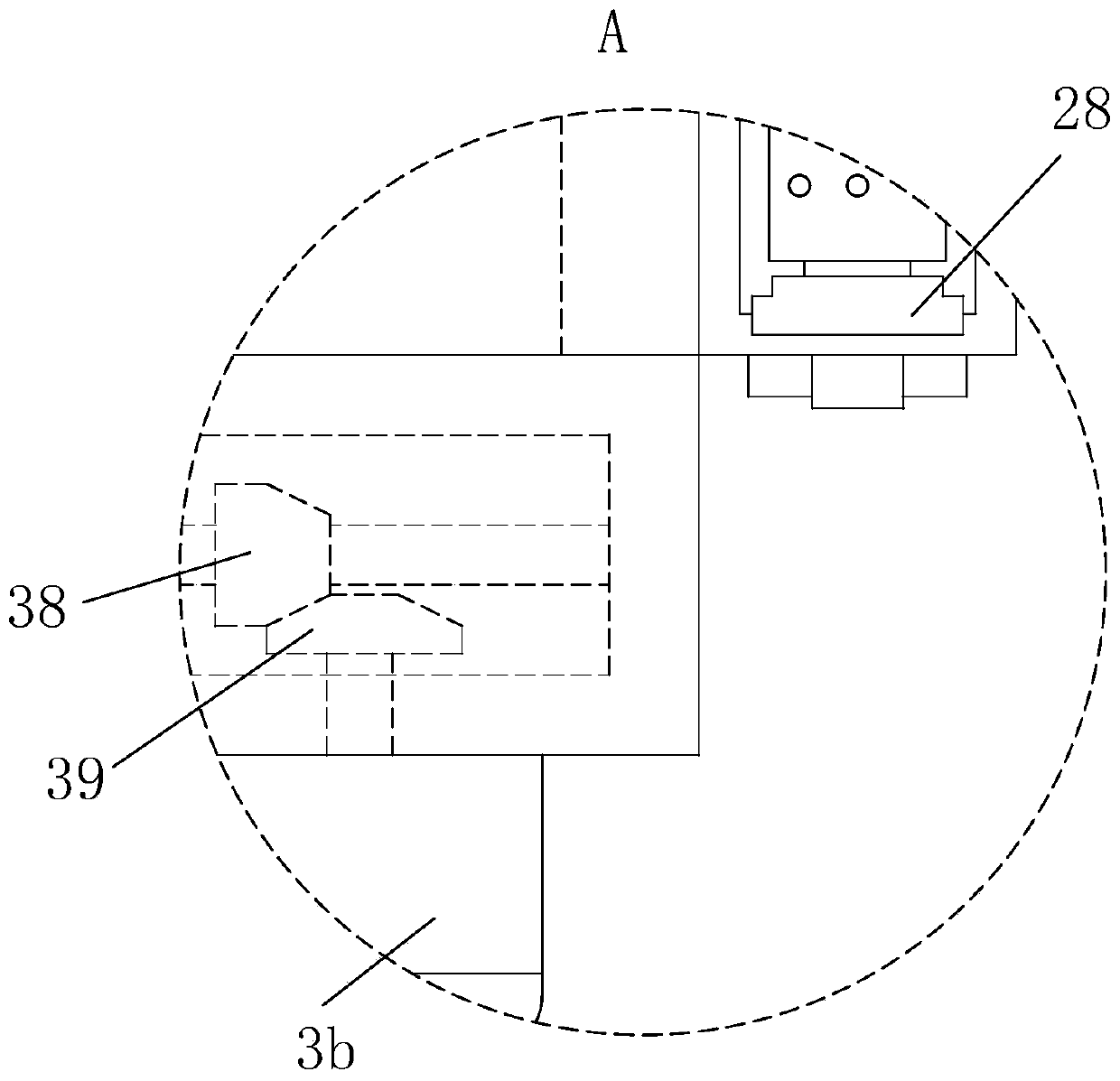

[0020] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , a gas cooker comprising: a cooker body 1, a cleaning structure 2, a dust-blocking structure 3 and a slide rail structure 5, the cleaning structure 2 is connected to the cooker body 1, and the cleaning structure 2 includes a first elongated frame 21, a first wire Rod 22, Z-shaped strip bar 23, first slide block 24, first motor 25, cleaning roller brush 26 and collection box 27, stove body 1 rear side wall connects the first strip frame 21, the first strip Two symmetrically arranged first sliders 24 are slidably connected inside the frame 21, and a first motor 25 is installed on the outer wall of the first long frame 21, and the output end of the first motor 25 passes through the first long frame 21 and is connected to the first wire Rod 22, the inside of the first slide block 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com