Measuring device and method for rock tensile strength

A technology for tensile strength and measuring devices, which is applied in the direction of measuring devices, strength characteristics, and the use of stable tension/compression to test the strength of materials, etc., which can solve the problems of difficult preparation of test pieces, large dispersion of test results, and impact on test accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

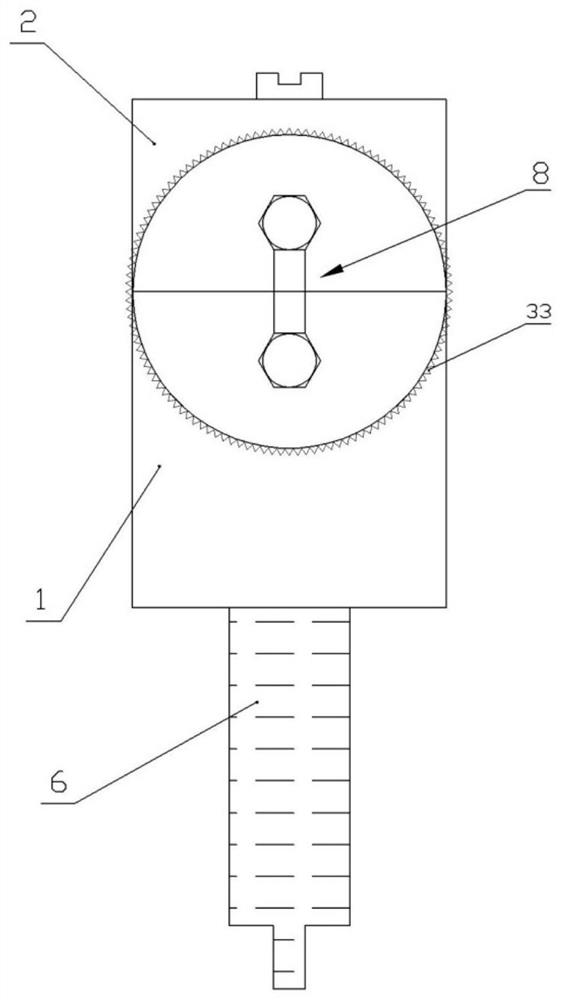

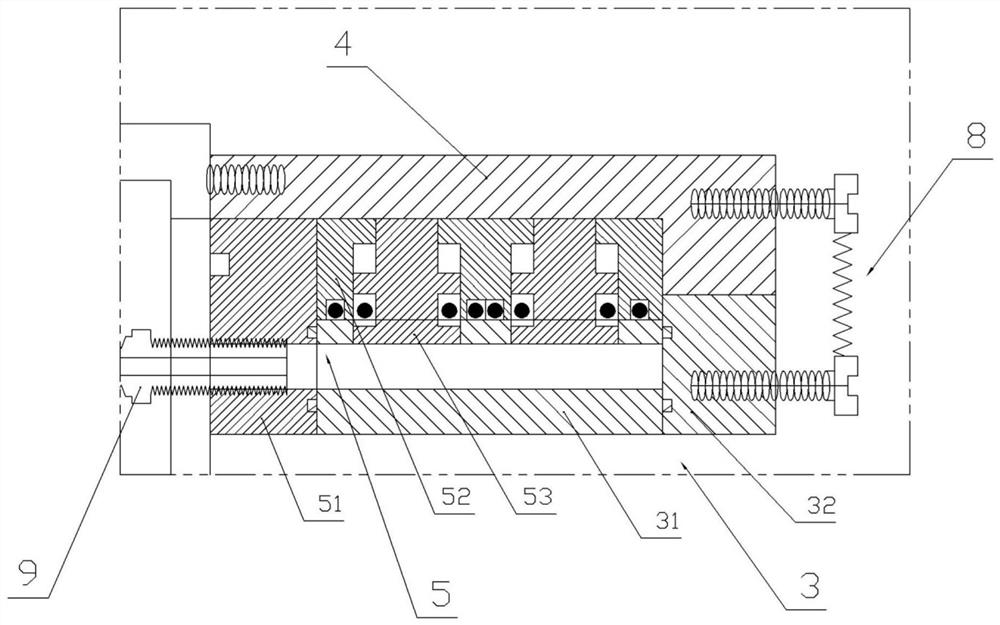

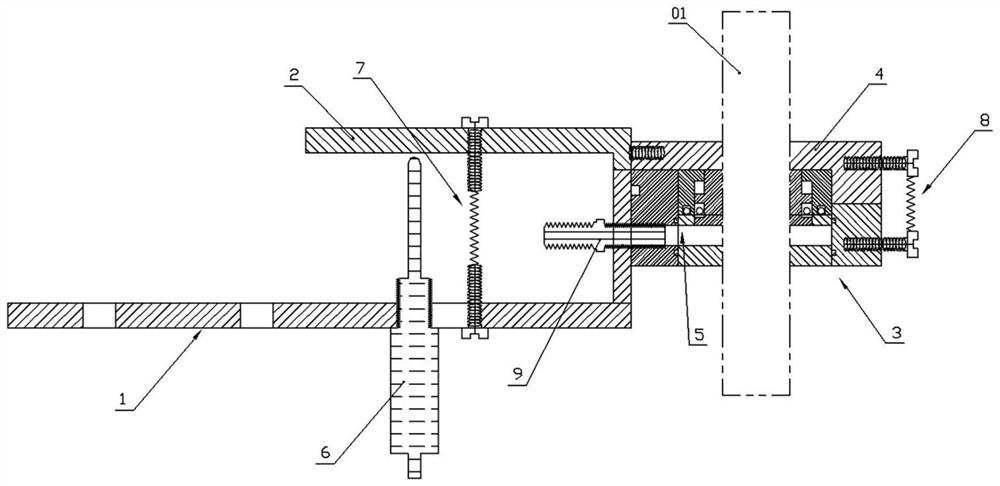

[0047] Such as figure 1 , figure 2 As shown, the rock tensile strength measuring device disclosed in this embodiment includes a lower seat 1, an upper seat 2, a lower pressure block 3, an upper pressure block 4, a force applying mechanism 5, a displacement sensor 6, a vertical Tension reset mechanism 7 and transverse tension reset mechanism 8.

[0048] Both the lower seat 1 and the upper seat 2 are L-shaped seat bodies. Both the horizontal section and the middle part of the vertical section of the lower seat 1 are provided with through holes, and the upper seat is buckled upside down on the lower seat and tensioned by the vertical tension reset mechanism 7, which includes a pair of tension bolts 71 With the tension spring 72, two tension bolts are arranged vertically relative to each other, the tension bolt on the top is threaded on the upper seat 2, the tension bolt on the bottom is threaded on the lower seat, and the tension spring is connected to the two tension bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com