Locomotive key-lifting switch plug wire calibrator

A technology of toggle key and locomotive, which is applied in the field of locomotive toggle switch plug line calibration device, which can solve the problems of low and difficult detection efficiency, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

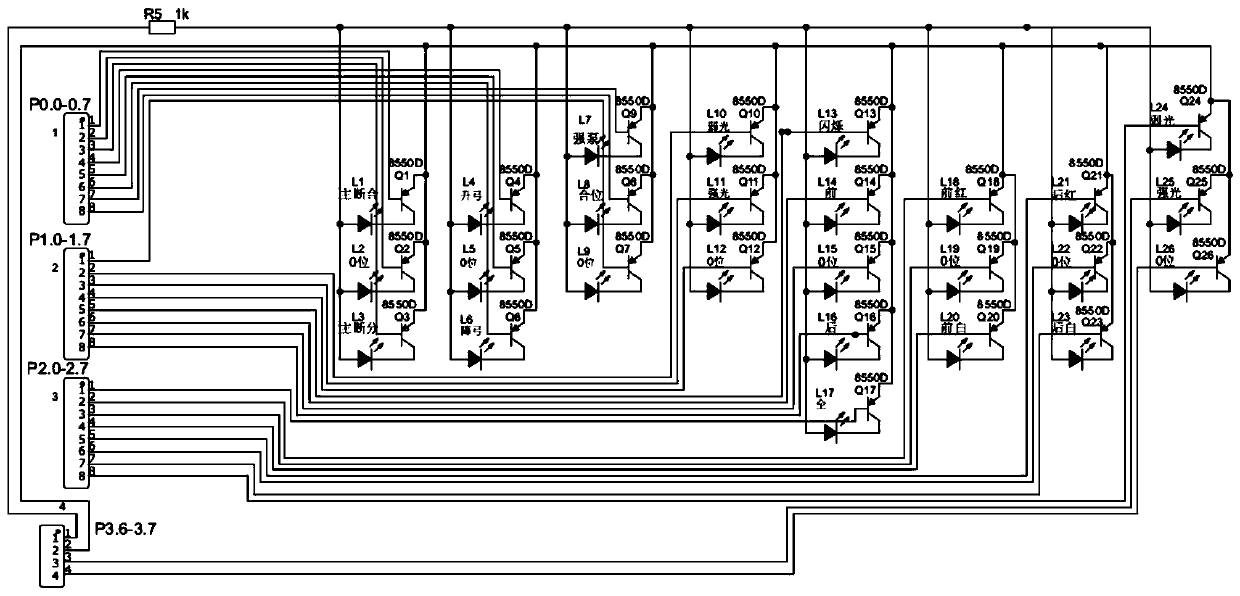

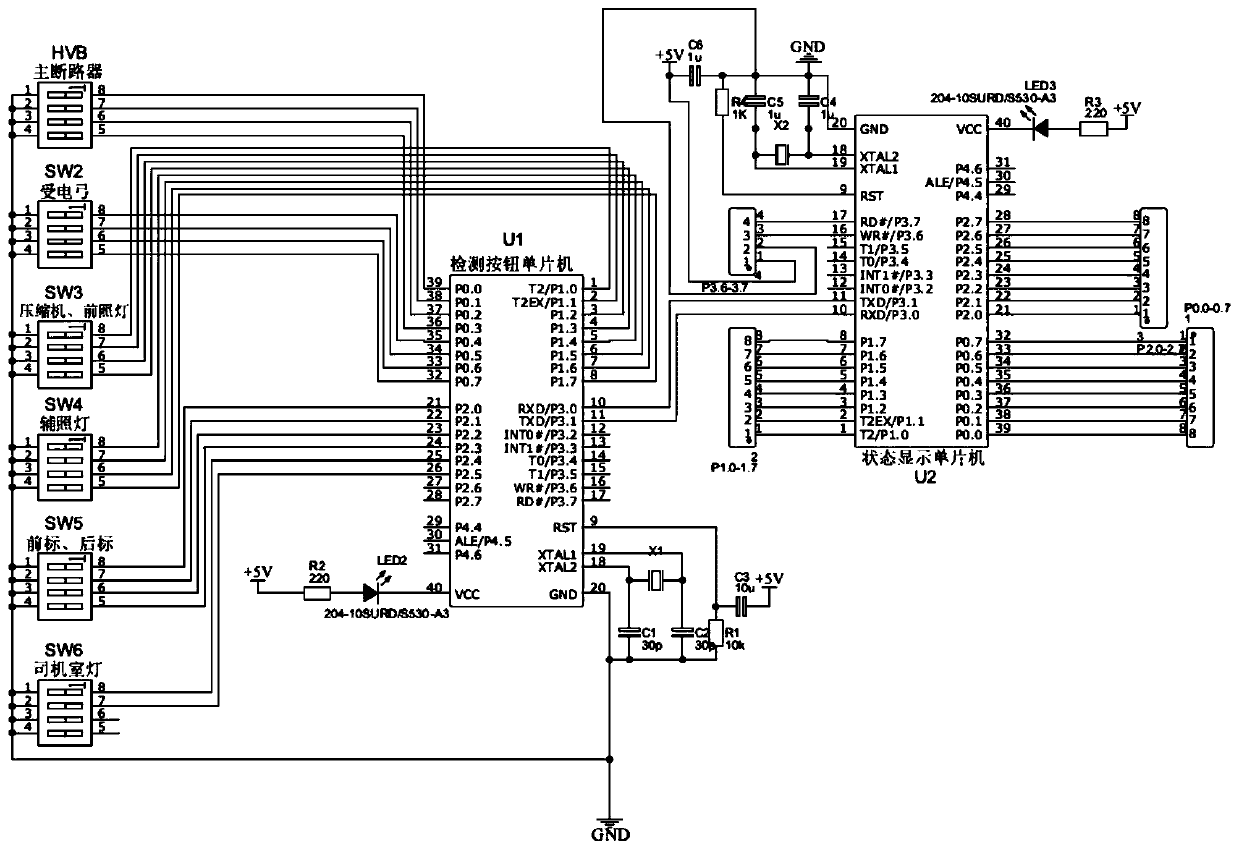

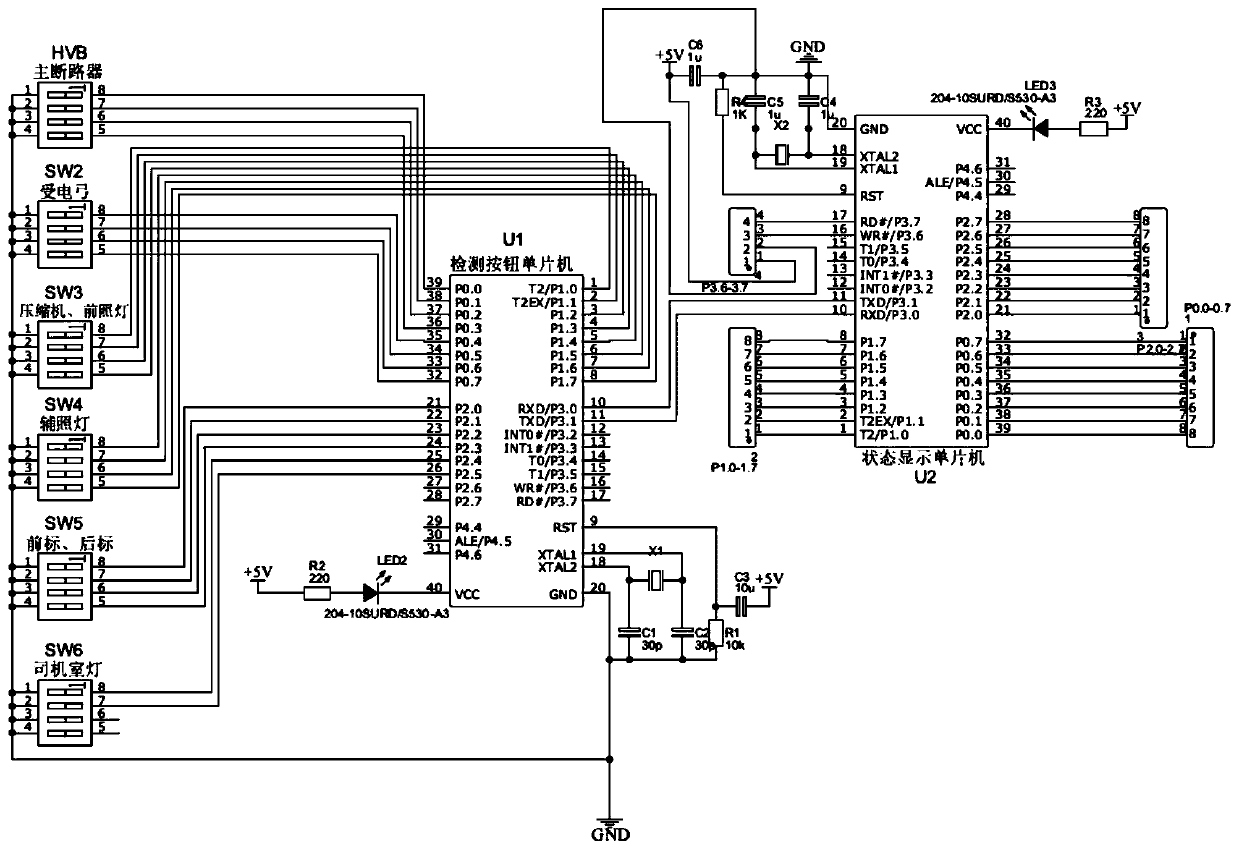

[0033] The locomotive toggle switch plug alignment device includes a single-chip microcomputer U1 for signal acquisition of the toggle switch group and a single-chip microcomputer U2 for output control LED display, wherein the single-chip microcomputer U1 is connected with the toggle switch group, and the single-chip microcomputer U2 is respectively connected with the single-chip microcomputer U1 and the indicator light;

[0034] The single-chip microcomputer U1 and the single-chip microcomputer U2 are respectively connected to a crystal oscillator circuit, and the VCC terminals of the single-chip microcomputer U1 and the single-chip microcomputer U2 are connected to a 5V power supply; the RXD terminal of the single-chip microcomputer U1 is connected to the TXD terminal of the single-chip microcomputer U2, and the TXD terminal of the single-chip microcomputer U1 is connected to the RXD terminal of the single-chip microcomputer U2;

[0035] The MCU U1 sequentially scans the input...

Embodiment 2

[0045] Such as figure 2 As shown, the single-chip microcomputer U1 and the single-chip microcomputer U2 adopt the STC8952RC single-chip microcomputer. The locomotive is a HXD1C electric locomotive, and the HXD1C electric locomotive console toggle switch group is the master electrical appliance used to directly operate the locomotive control circuit.

[0046] The HXD1 C-type electric locomotive console toggle switch group controls the locomotive, the main circuit breaker, the pantograph, the compressor, the headlight, the auxiliary light, the marker light, and the driver's cab light. There are seven kinds of equipment in total. The toggle switch is mainly composed of a toggle for the operator to control, a linkage cam, a micro switch group, a connecting wire and a plug. Each controlled function block has a separate cam-microswitch combined structure. According to different functional requirements, the number of control nodes of each group of switches is also different. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap