Micromechanical presssure sensor device and corresponding production method

A pressure sensor and micro-mechanical technology, which is used in the measurement of fluid pressure, the pressure difference measurement between multiple valves, and the measurement of fluid pressure through electromagnetic components. It can solve the problems of reduced mechanical stability and pressure sensor tolerance. Achieve the effect of improved precision and high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

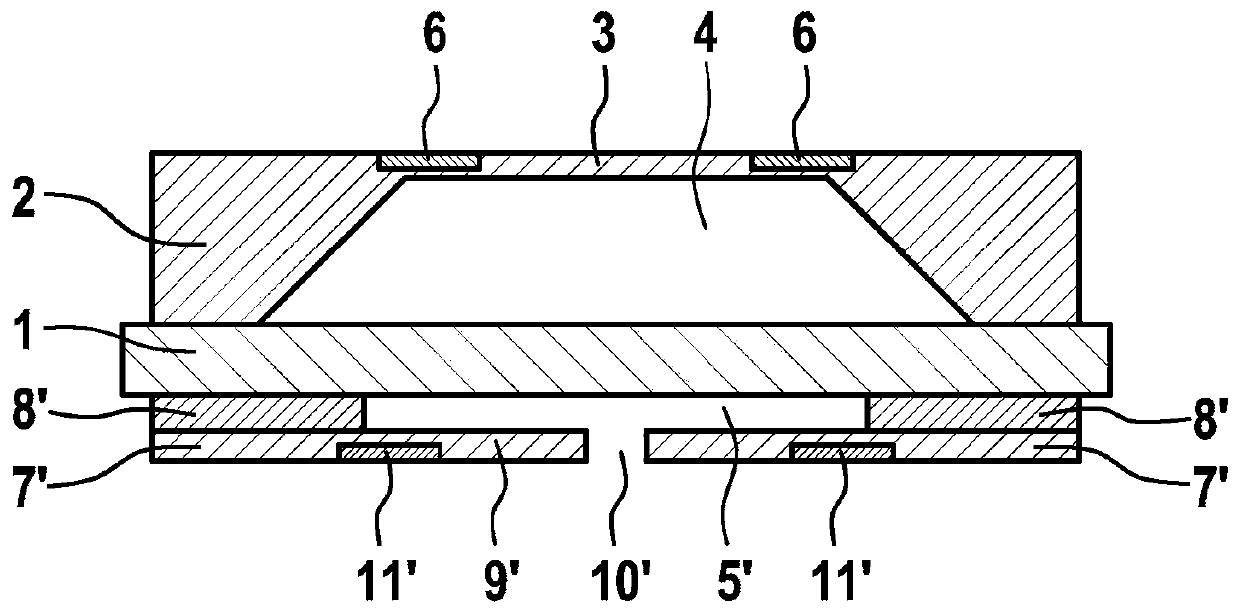

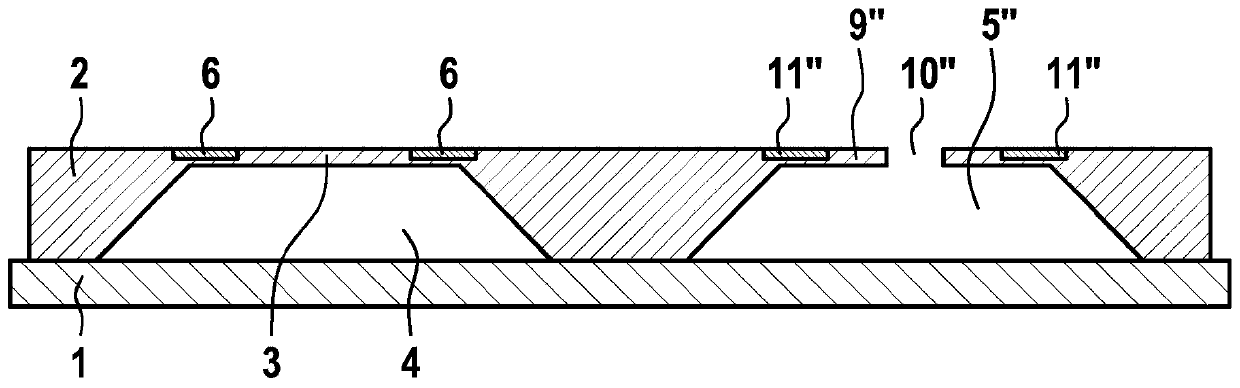

[0028] In the figures, identical reference numbers indicate identical or functionally identical elements.

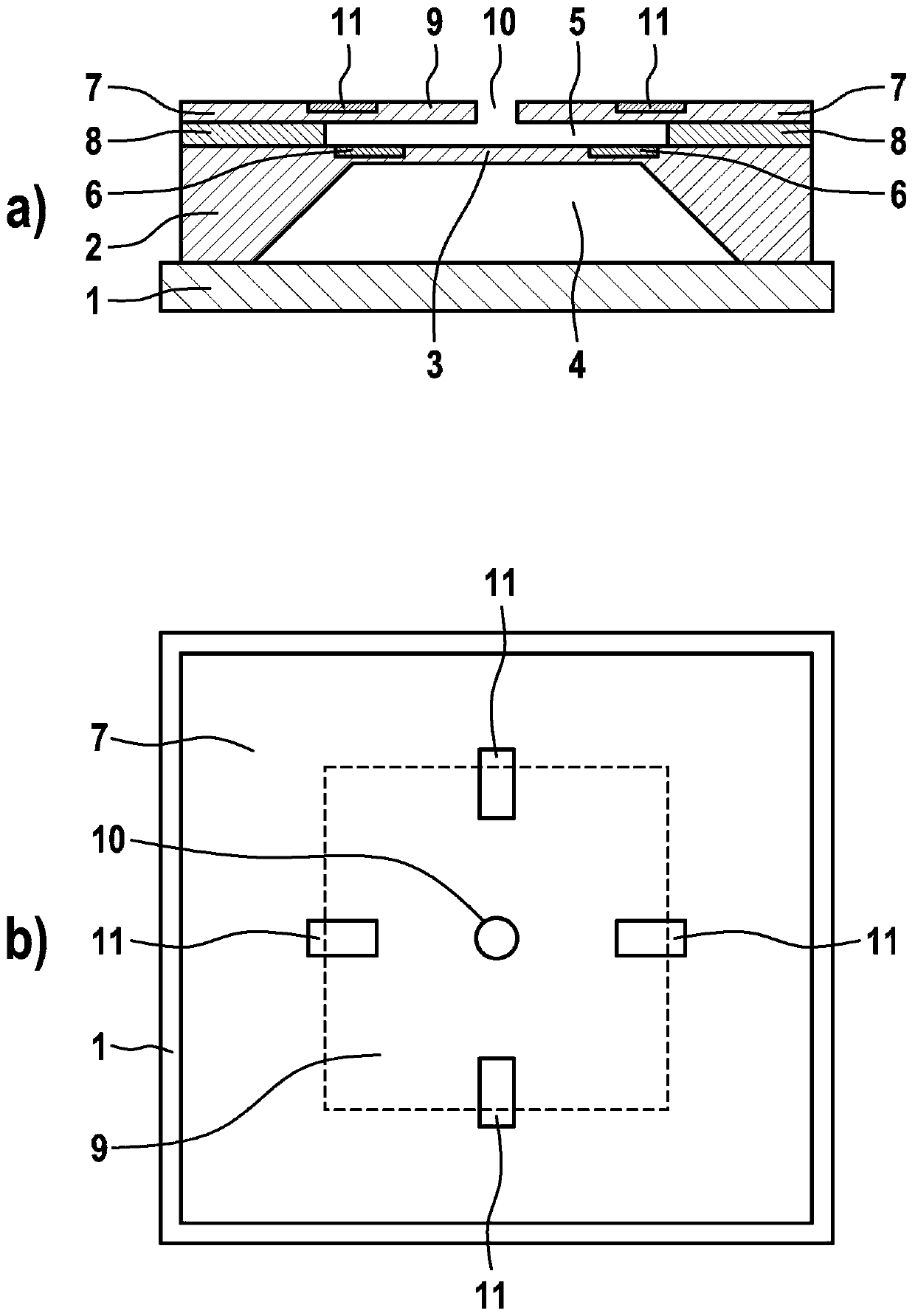

[0029] figure 1 a), b) are schematic representations of a micromechanical pressure sensor device according to a first embodiment of the invention, more precisely, figure 1 a) is a cross section and figure 1 b) is a top view.

[0030] exist figure 1 In a), b), the reference numeral 2 designates a first micromechanical functional layer, for example a silicon layer, in which the first membrane 3 and the cavity adjoining the first membrane are formed 4. A sealing layer 1 , for example likewise a silicon layer, is arranged on the side of the first micromechanical functional layer 2 opposite the membrane 3 , by means of which sealing layer the first cavity 4 is closed. In the present case, the first membrane 3 is likewise closed, so that a constant pressure is contained in the first chamber 4 .

[0031] A first bending sensing device 6 with a piezoresistive element i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com