Energy-saving full-automatic shoe sole cleaning machine

A fully automatic, cleaning machine technology, applied in the direction of cleaning boots and shoes, cleaning equipment, household cleaning devices, etc., can solve the problems of poor cleaning effect, low cleaning efficiency, poor safety and comfort, etc., to achieve easy installation and The effect of maintenance, high structural adaptability and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

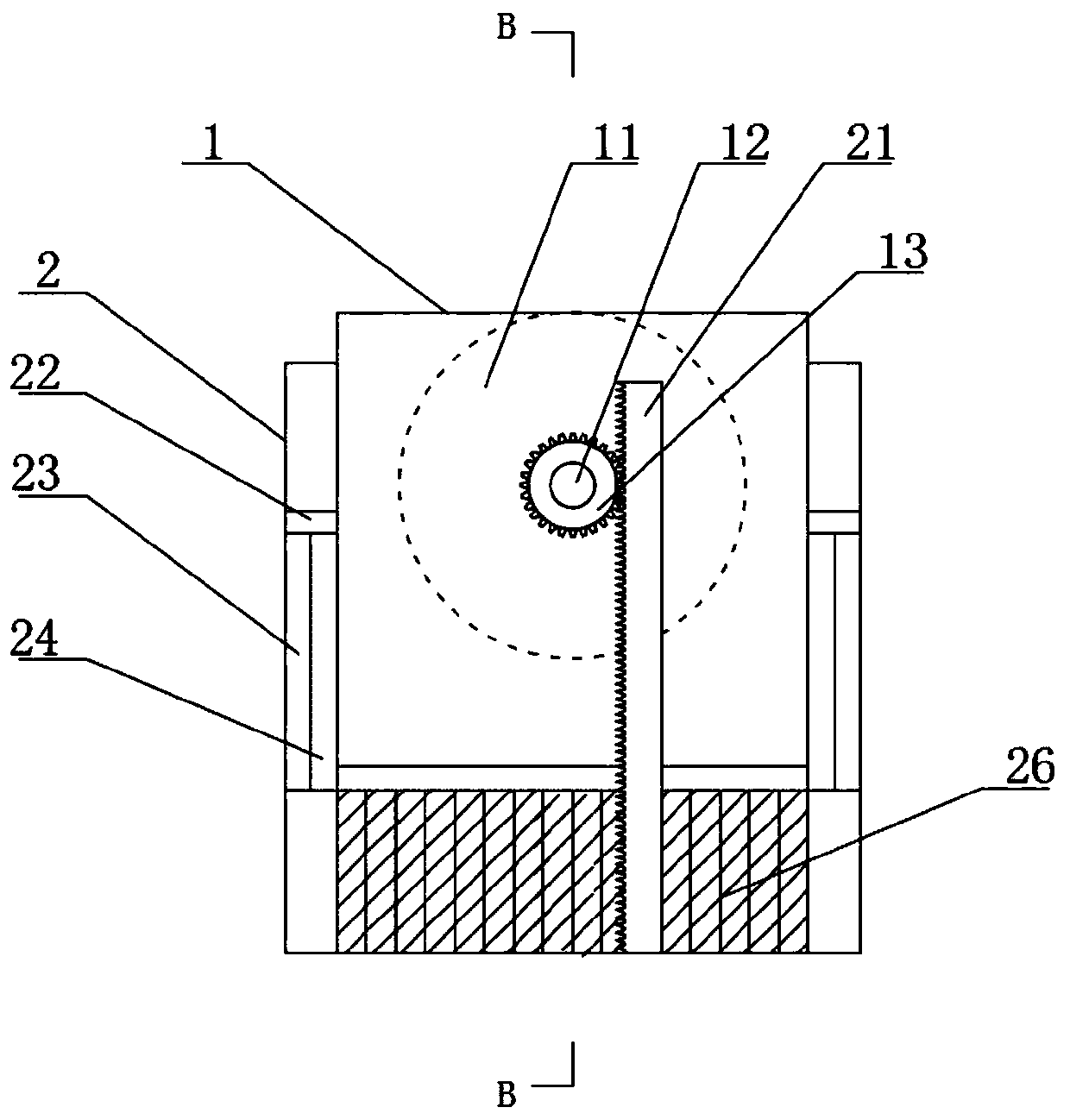

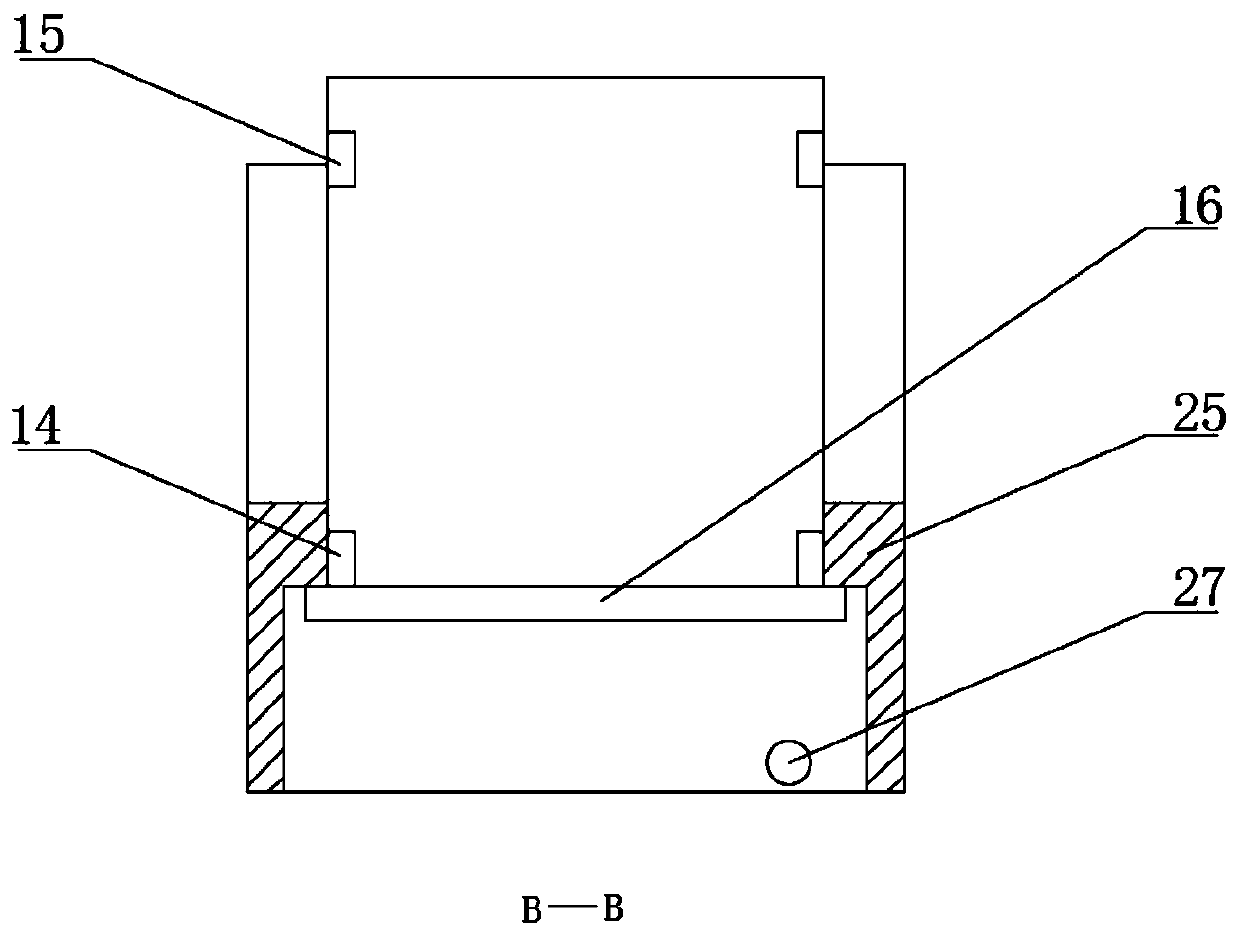

[0034] see figure 1 and Figure 4 , an energy-saving fully automatic shoe sole cleaning machine, including a shoe cleaning drive module and a shoe sole cleaning module, wherein:

[0035] The driving module for brushing shoes includes a fixed outer sleeve 2 and a movable inner sleeve 1. The bottom of the movable inner sleeve 1 is connected with the bottom of the fixed outer sleeve 2 through a spring 26 (the spring 26 adopts several spring posts arranged side by side). Both sides of the sleeve 1 are vertically provided with strip-shaped sliders 24, and the corresponding position of the fixed outer sleeve 2 is provided with a chute 23, and both sides of the movable inner sleeve 1 and the fixed outer sleeve 2 pass through the sliders 24. Connect with the chute 23.

[0036] In order to prevent the chute 23 and the slider 24 from hindering the stepping, the slider 24 is arranged at the position below the two sides of the movable inner sleeve 1, the installation height of the chute...

Embodiment 2

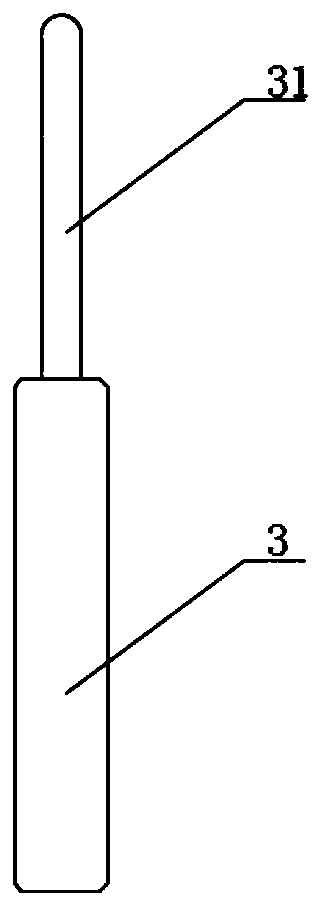

[0043] see image 3 , this embodiment also includes the following features on the basis of embodiment 1:

[0044] The following cleaning needle structure can be applied to the cleaning of soles in snowy days:

[0045] The rotating shoe brush 11 is a plurality of groups of hard cleaning needles arranged radially closely. The hard cleaning needles are of a capsule-shaped snow-cleaning structure, which includes an airbag 3 and a columnar small capsule 31 connected thereto. When the columnar capsule 31 was stepped on, the internal air pressure made the columnar capsule 31 not stepped on stretch into the groove of the sole to extrude residual snow.

Embodiment 3

[0047] On the basis of embodiment 1, this embodiment also includes the following features:

[0048] The cleaning module also includes a water spray module. The water spray module includes a nozzle arranged above the movable inner sleeve 1 and an air pressure water chamber arranged below the movable inner sleeve 1. The air pressure water chamber is connected to the nozzle. When the movable inner sleeve 1 is subjected to When the pressure is downward, the air pressure water chamber controls the nozzle to spray the sole. The bottom of the movable inner sleeve 1 is connected with a corresponding drainage pipeline.

[0049] The air pressure water cavity is connected with a water supply structure, and the air pressure water cavity is replenished in time by setting a one-way valve. When the internal pressure of the air-pressure water chamber increases, water is sprayed toward the sole through the nozzle; when the air-pressure water chamber moves upward with the movable inner sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com