Cartilage slicing knife

A slicing knife and cartilage technology, applied in bone implants, medical science, nose implants, etc., can solve the problems of small costal cartilage, inconvenient cutting, and easy deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

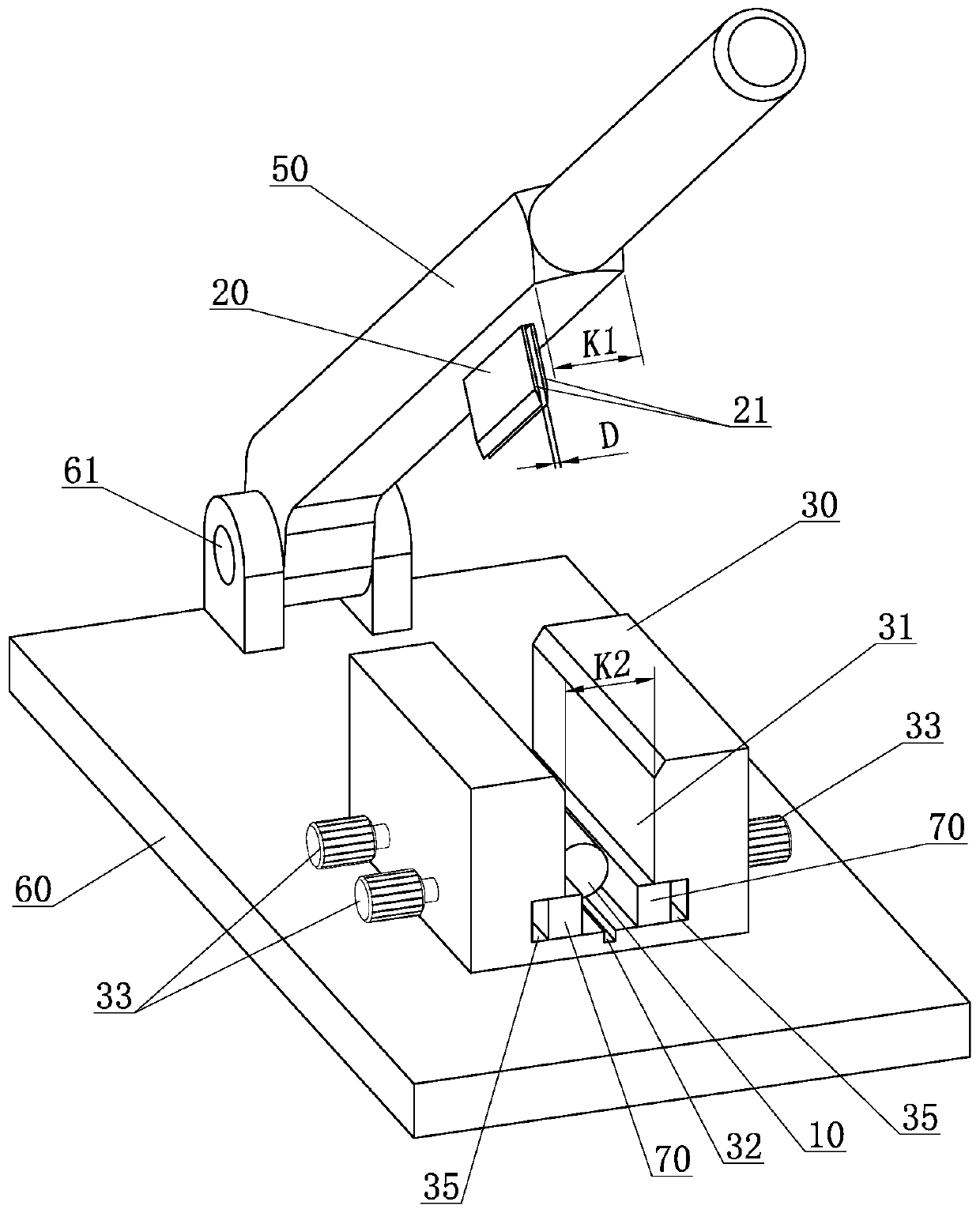

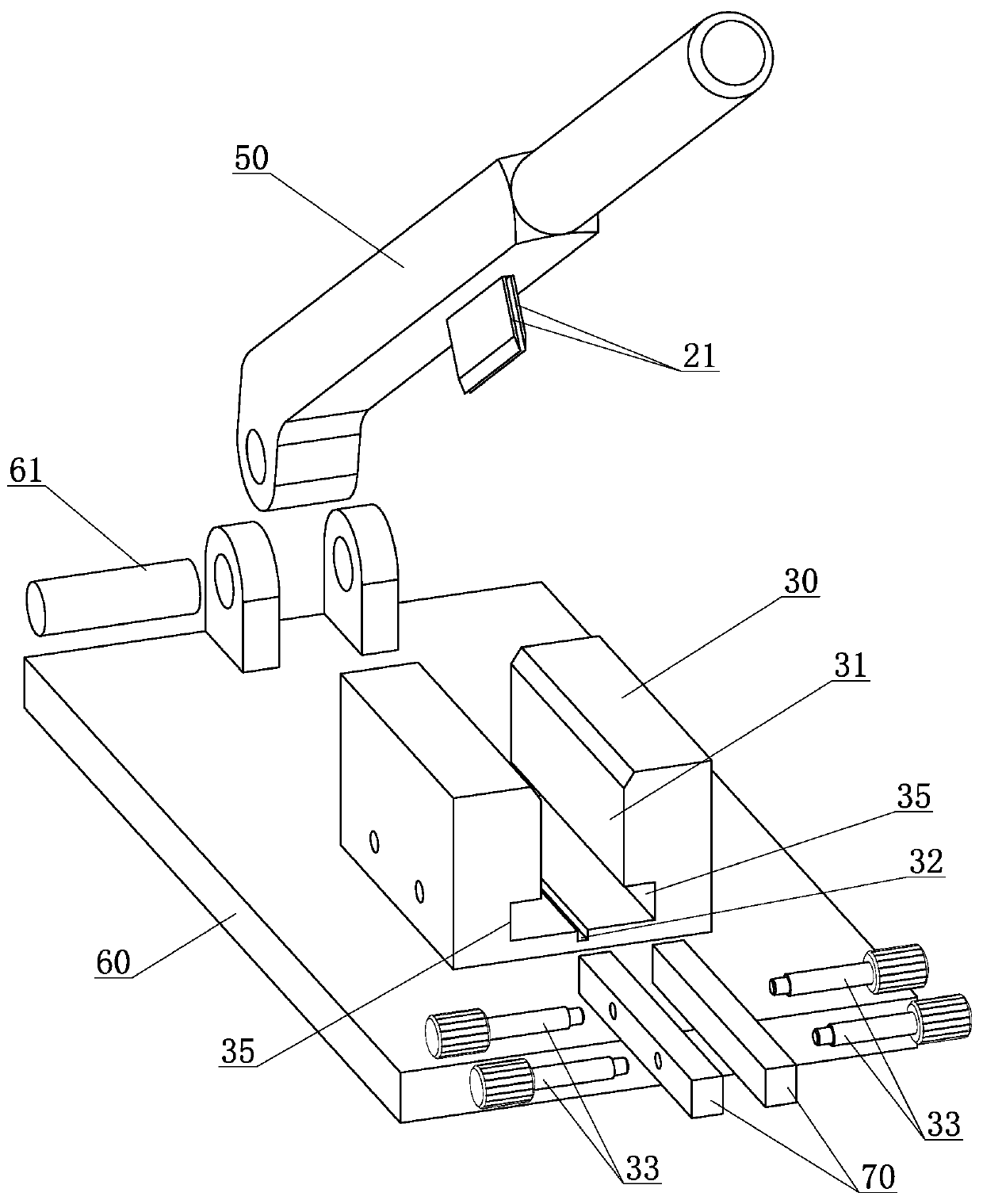

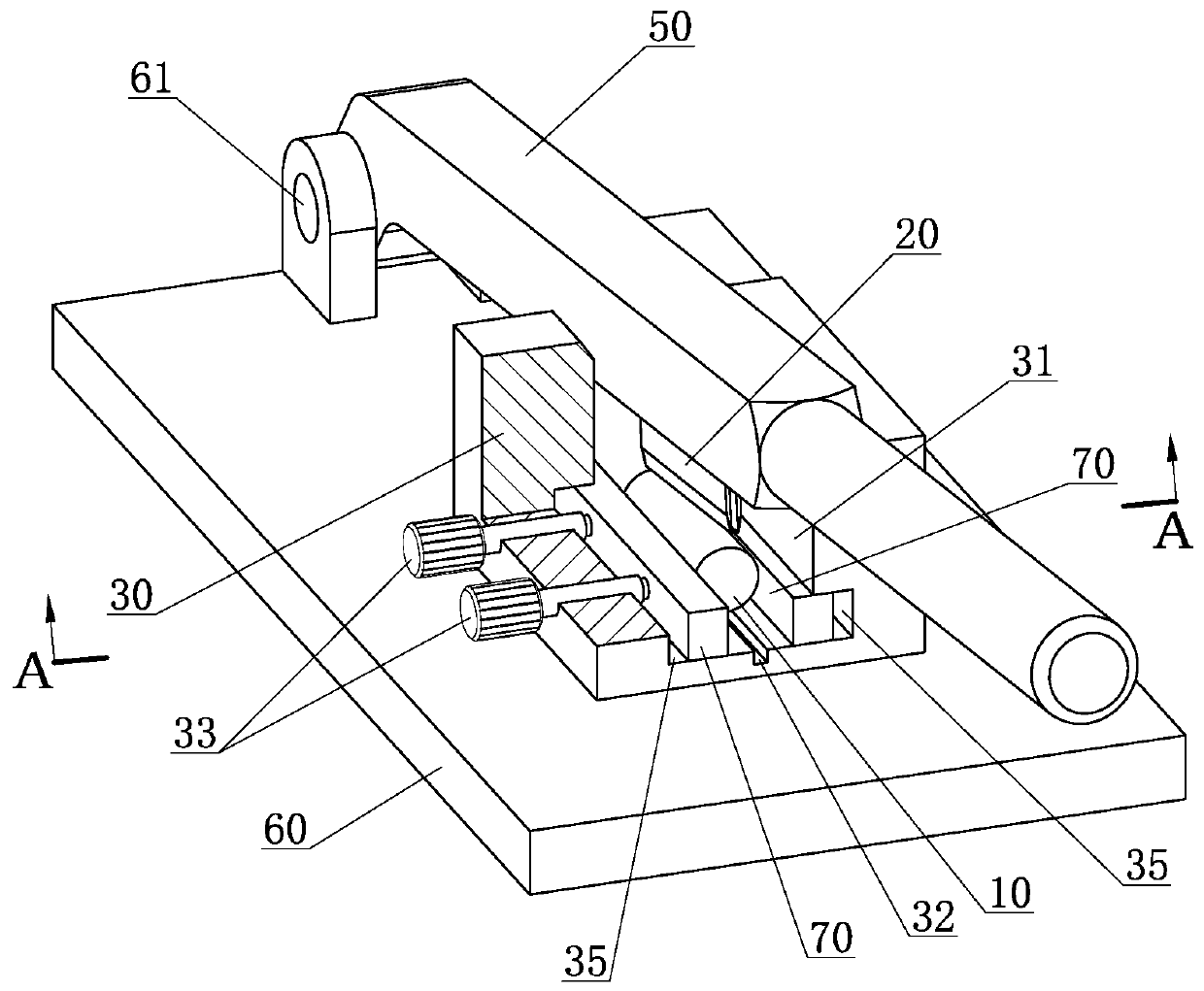

[0040] Such as Figure 1 to Figure 5 , a cartilage slicing knife used for cutting cartilage slices from costal cartilage 10, including a cutting knife 20 and a base 30.

[0041] The costal cartilage is a piece of cartilage taken from the ribs of the human body. Its shape is close to a cylinder and its diameter is about 10mm. Thick slices of cartilage.

[0042] The cutter 20 is a double-edged cutter provided with two blades 21, and a gap D=1mm corresponding to the thickness of the cartilage sheet is arranged between the two blades.

[0043] The cutting knife 20 is installed on the knife bar 50, and the front end of the knife bar is hinged with the bottom plate 60 through the rotating shaft 61 to form a guillotine structure, and the knife bar drives the cutting knife to cut into the costal cartilage downward. The width K2 of the chute corresponds to the width K1 of the knife shank, into which the shank can enter with a sliding fit, as in image 3 shown.

[0044] The base 30 ...

Embodiment 2

[0049] Such as Figure 6 , a cartilage slicer. This embodiment is a structural improvement of the first embodiment.

[0050] In this embodiment, a side positioning block 70 is respectively provided on both sides of the trough 31, and reset holes 71 corresponding to the positions are respectively provided at both ends of the two side positioning blocks. There is reset shaft 72, which slides and fits with the positioning holes of two or two side positioning blocks, and reset spring 73 is sleeved on the reset shaft, and the reset spring is arranged between the two side positioning blocks. A side positioning block is used to move the two positioning blocks to separate.

[0051] The structure of this embodiment can keep the two side positioning blocks stably in the material placement chute. The return spring can also promote the separation of the two side positioning blocks to facilitate the placement and removal of the costal cartilage.

Embodiment 3

[0053] Such as Figure 7 to Figure 8 , a cartilage slicer. This embodiment is a structural improvement of the first embodiment.

[0054] A cutter guide block 40 that presses the costal cartilage from the upper end is arranged in the feeding trough. The width K3 of the cutter guide block corresponds to the width K2 of the feeding chute, and the cutter guide block can be embedded into the feeding chute with a sliding fit. Bolt holes 47 are respectively provided at both ends of the cutter guide block, and the bolt holes 47 are stepped holes, and a pressure regulating spring 46 is arranged in the bolt holes 47 . The bottom plate is provided with screw holes 37 at positions corresponding to the bolt holes 47 . The two ends of cutter guide block are provided with guide block bolt 45, and guide block bolt 45 is screwed into the screw hole 37 of base, and guide block bolt presses cutter guide block on the described costal cartilage by pressure regulating spring 46.

[0055] The cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com