Support automatic repairing method based on additive manufacturing

An automatic repair and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of partial support printing failure, operation error, and increase the failure of part forming, so as to solve the printing risk of parts, improve production efficiency, and improve the effect of forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

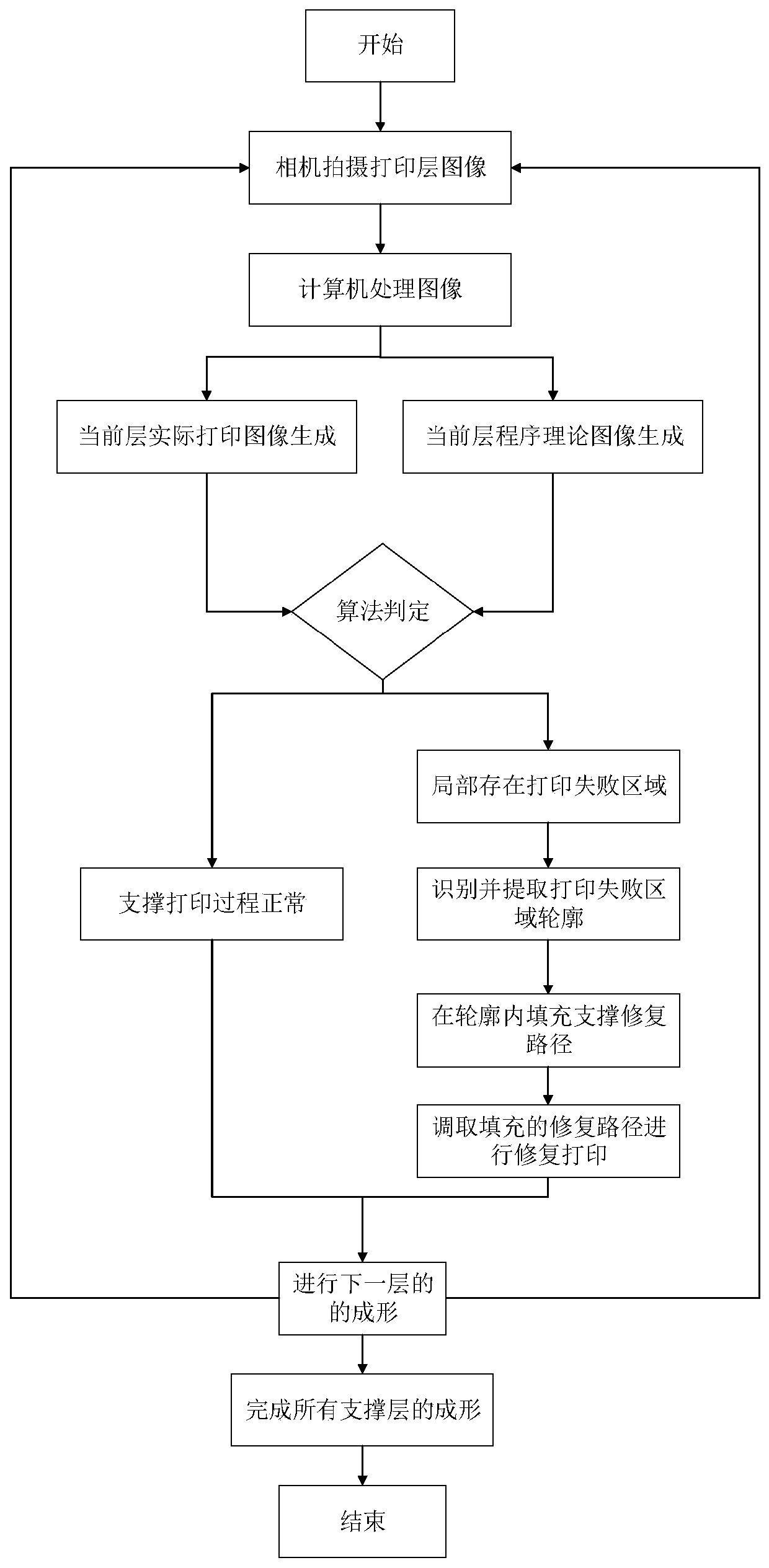

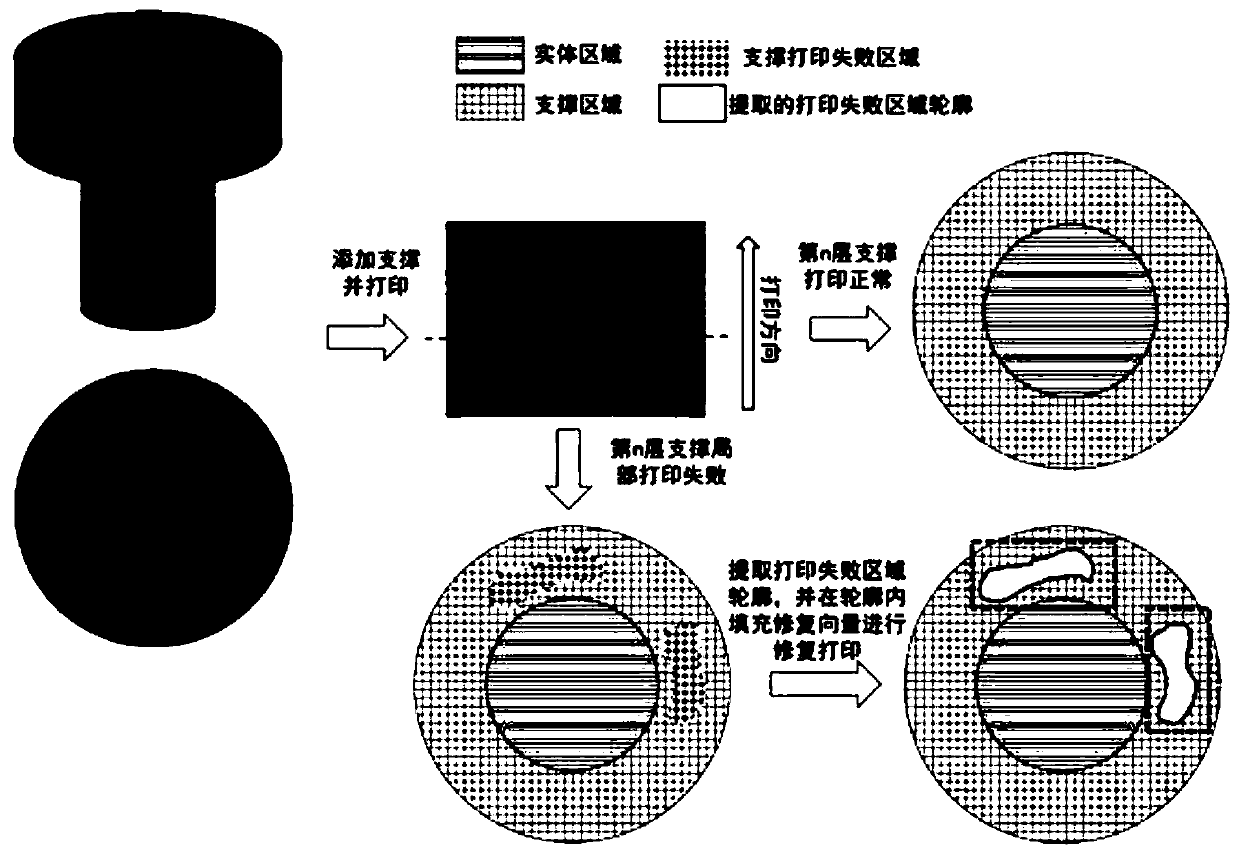

[0027] The present invention is a support automatic repair method based on additive manufacturing, the process of which is as follows figure 1 As shown, the principle is as figure 2 As shown, the specific steps are as follows:

[0028] Step 1, the support image of the printed layer is generated

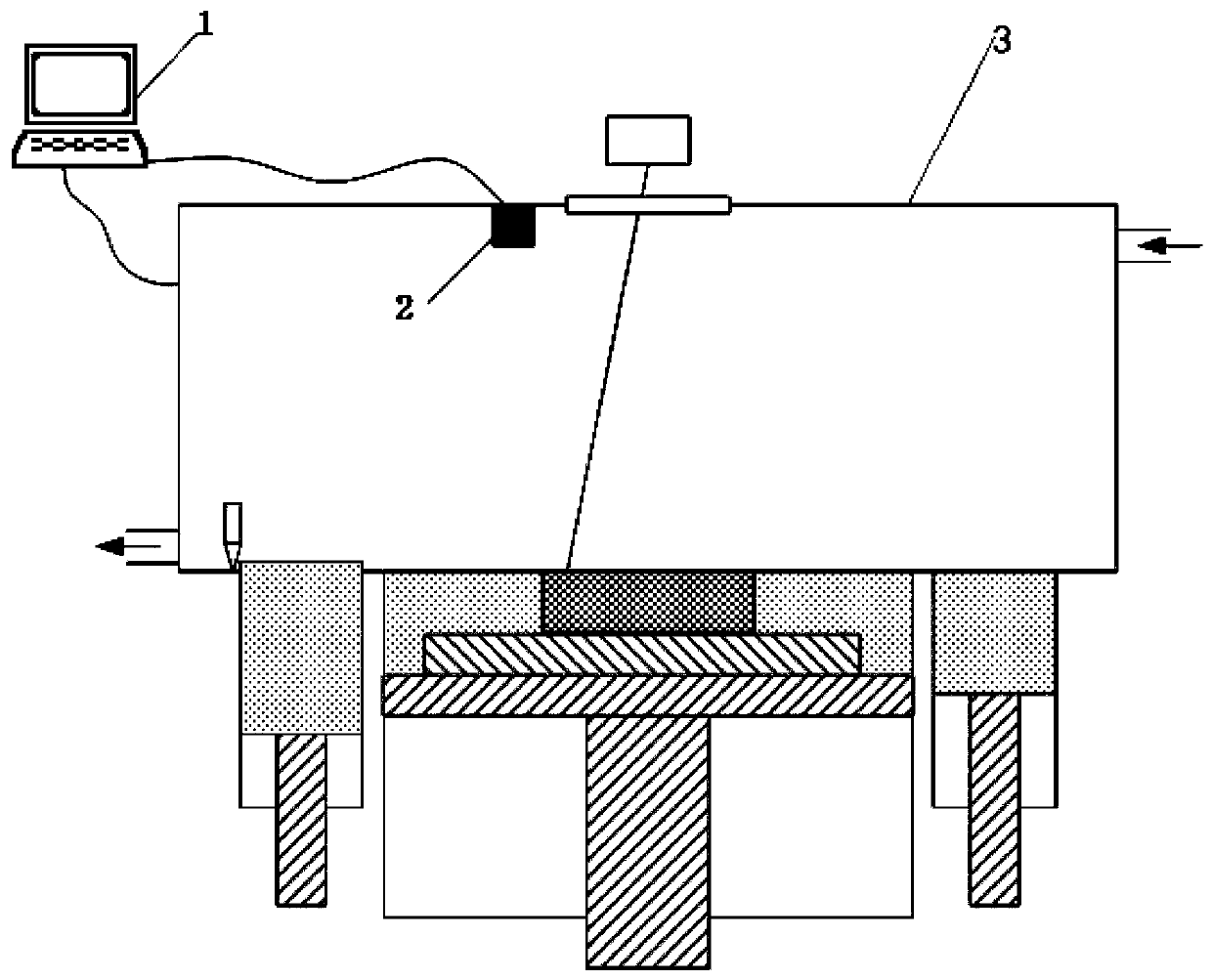

[0029] Such as image 3 As shown, the camera 2 is set on the top of the forming chamber, and is electrically connected to the computer control system 1 through a cable. The camera 2 collects the printed image information of each layer support during the forming process and feeds it back to the computer control system 1, specifically:

[0030] When a layer of powder is laid and the printing of the current layer support is completed, the camera 2 collects the image of the printing layer and feeds the image information back to the computer control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com