Light guide plate lattice point processing device based on double-rotating motor

A technology for light guide plate dots and processing devices, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc. The effect of saving processing time and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

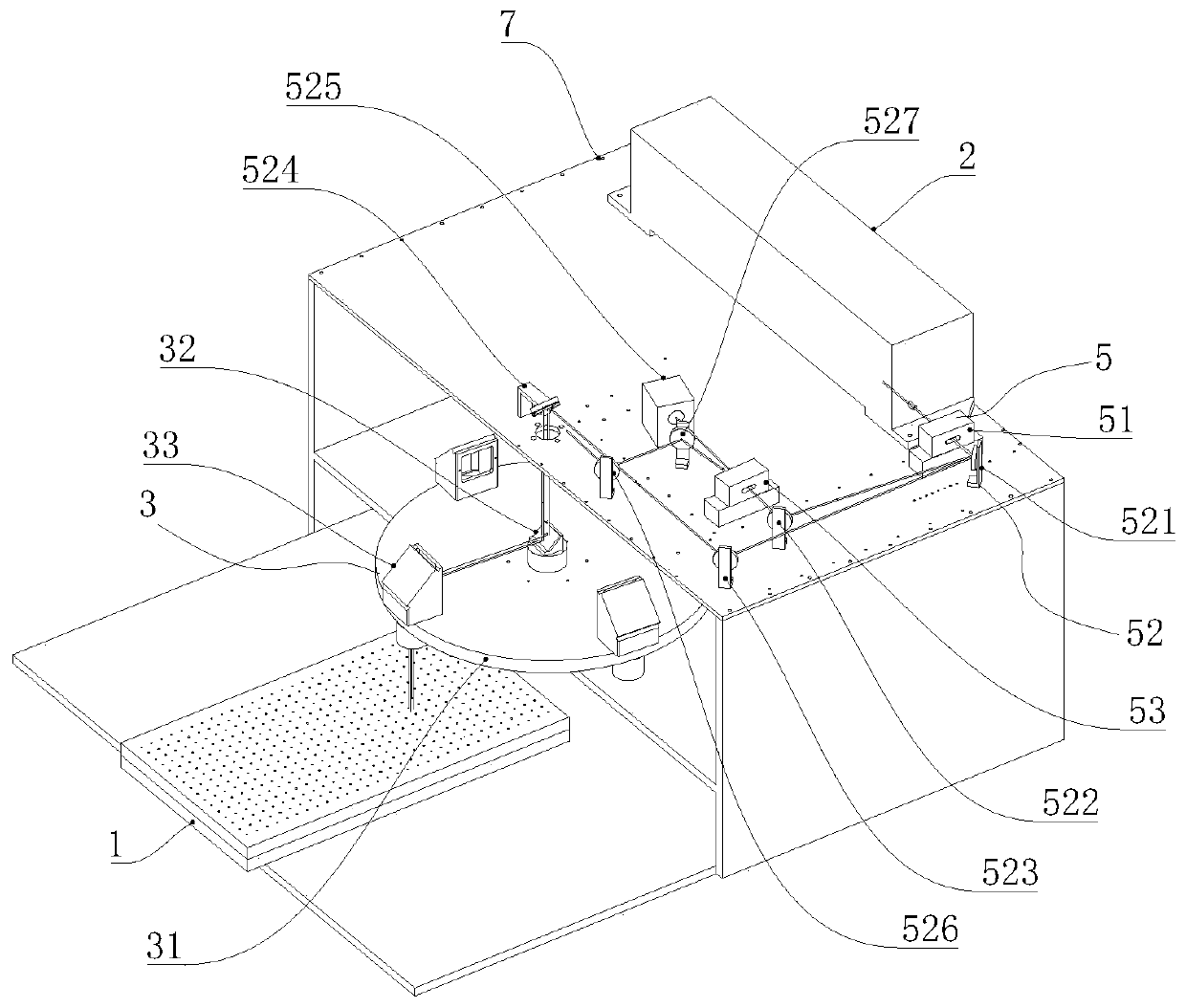

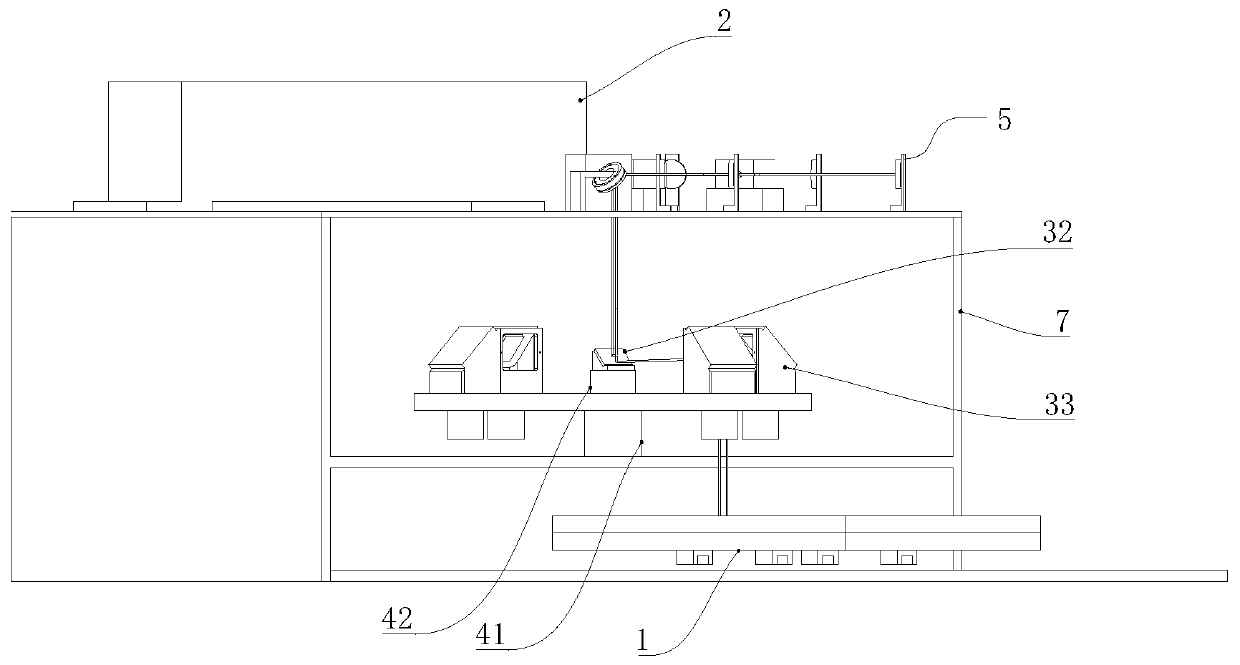

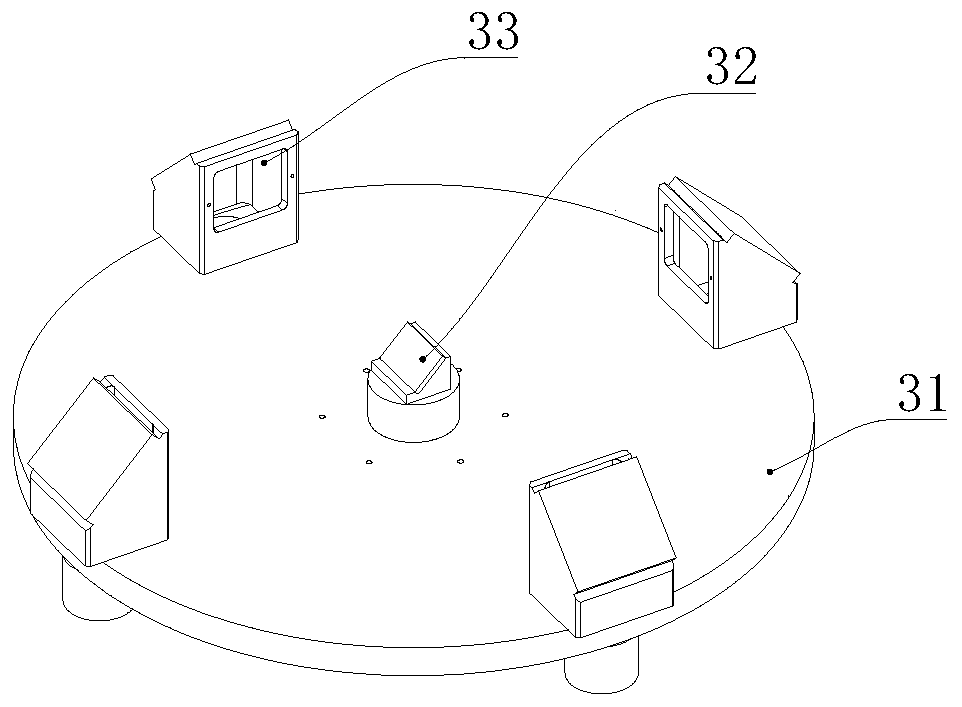

[0038] The laser adjustment mechanism 5 includes a first acousto-optic modulator 51 and a third reflector group 52, and the third reflector group 52 includes a third reflector 521, a fourth reflector 522, a fifth reflector 523, a sixth reflector Glass 524 and beam dissipator 525, the light incident end of the 3rd reflecting mirror 521 and the light emitting end of acousto-optic modulator 51 are arranged correspondingly, the light emitting end of the 3rd reflecting mirror 521 is respectively connected with the 4th reflecting mirror 522, the 5th reflecting mirror 523 The light incident end of the fourth reflecting mirror 522 is set correspondingly to the light incident end of the beam dissipator 525, and the light exit end of the fifth reflecting mirror 523 is correspondingly set to the light incident end of the sixth reflecting mirror 524. The light output end of the sixth reflective mirror 524 is connected to the light input end of the first reflective mirror group 32 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com