Magnetic sheet continuous feeding mechanism and its feeding method

A feeding mechanism and magnetic sheet technology, which is applied in the direction of conveyors, conveyor objects, and object destacking, etc., can solve problems such as difficulty in ensuring long-term continuous feeding, high labor intensity, and affecting the continuity of magnetic sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

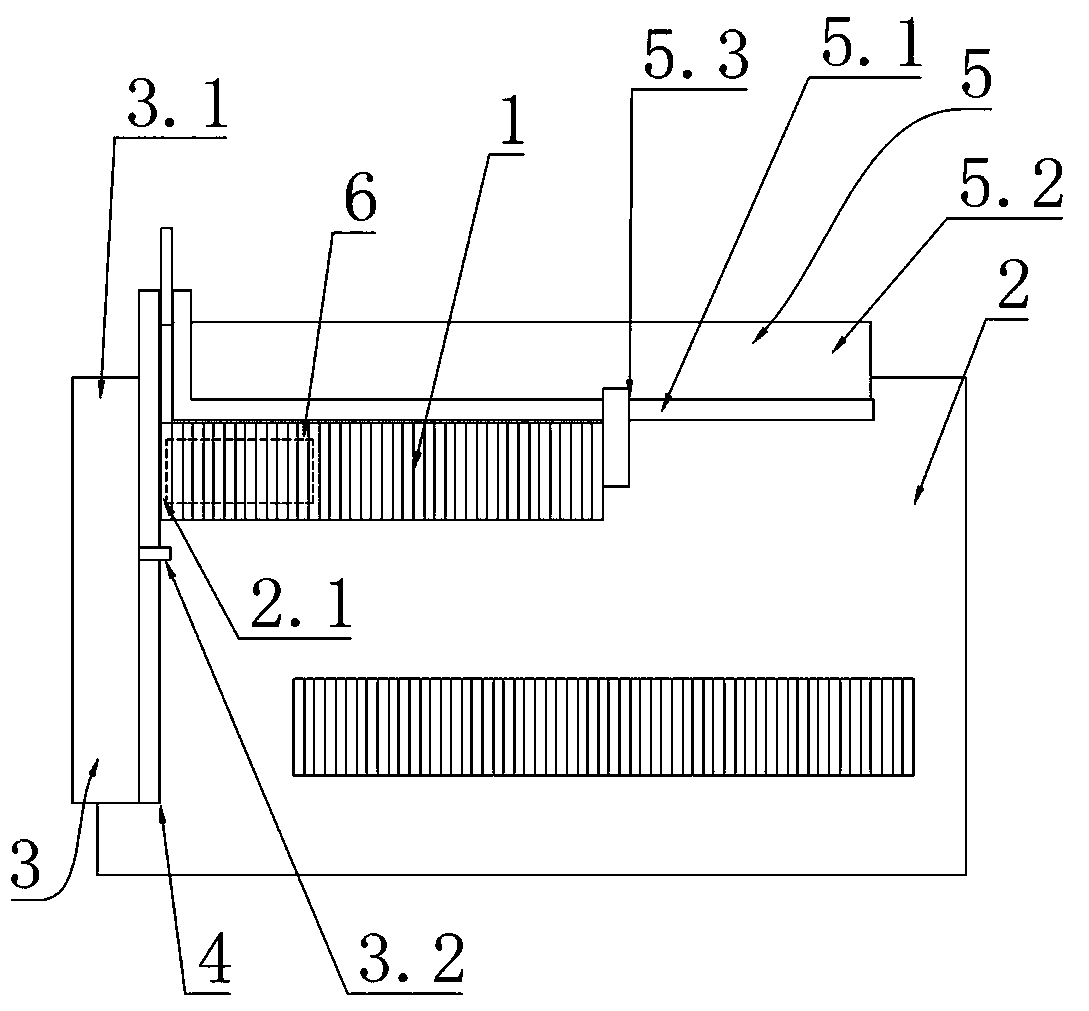

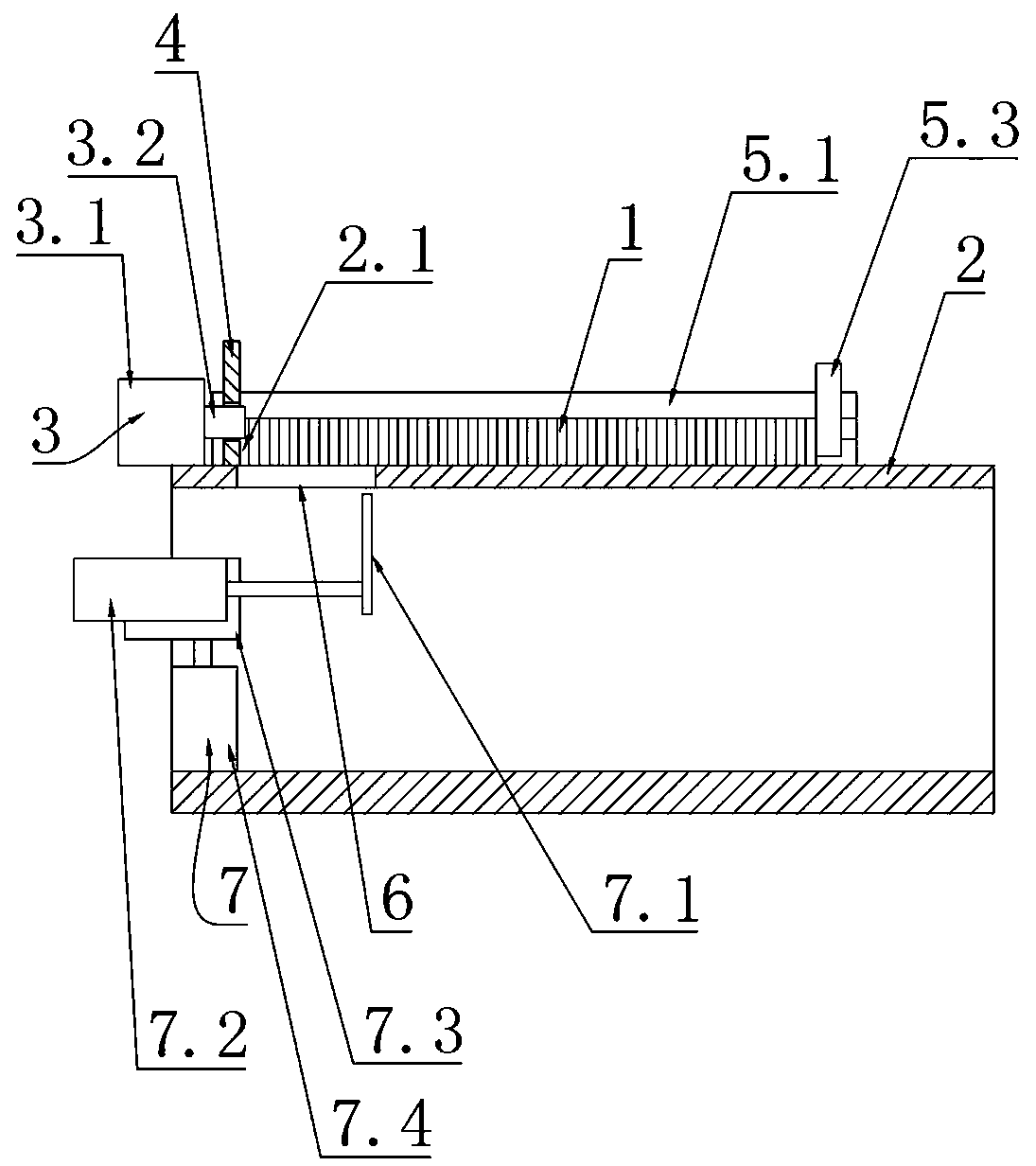

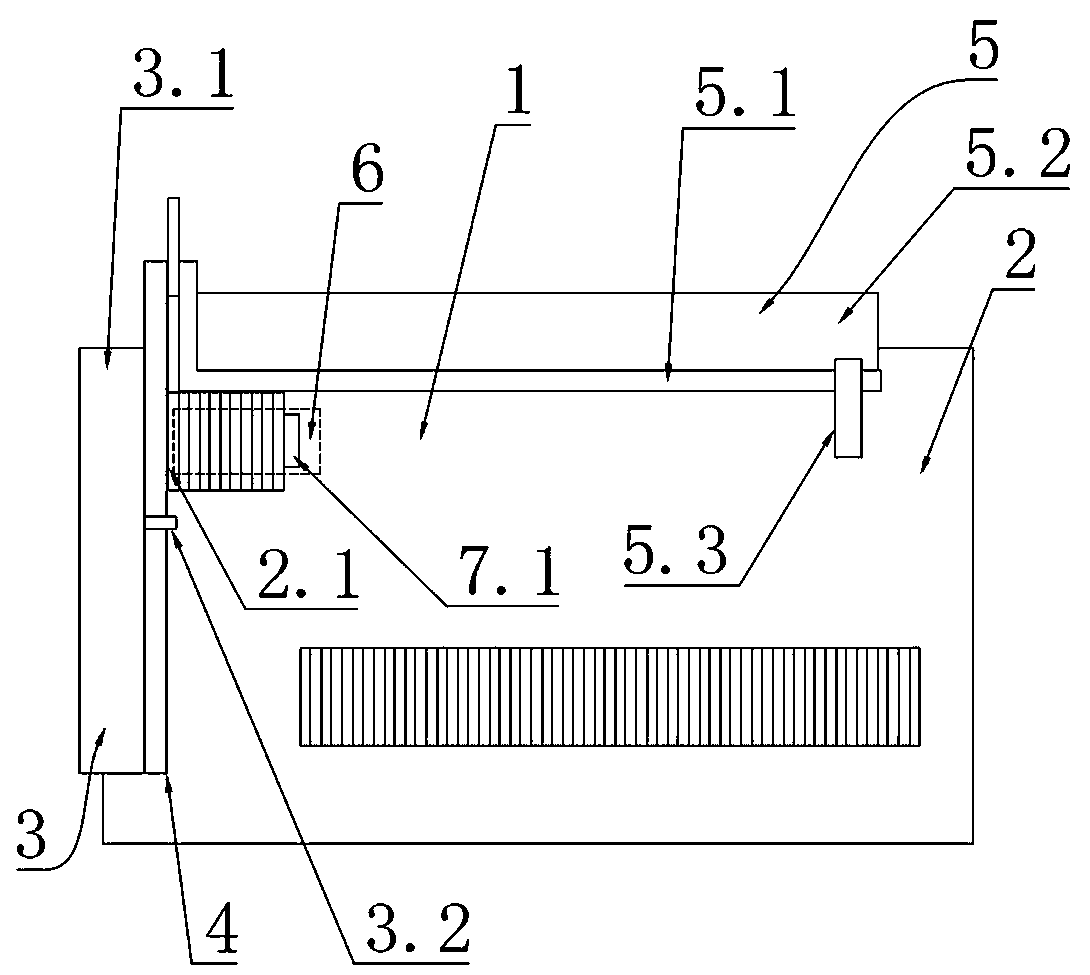

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as Figure 1~6 as shown,

[0029] A continuous feeding mechanism for magnetic sheets, comprising a feeding table 2 for placing a plurality of magnetic sheet bodies 1, the feeding table 2 is provided with a feeding position 2.1, and one end of the feeding position 2.1 is provided with a feeding assembly 3, the The feeding assembly 3 pushes out the magnetic sheet body 1 located at the feeding position 2.1, a baffle 4 is provided on one side of the feeding position 2.1, and a pushing assembly 5 is provided on the other side of the feeding position 2.1, and the pushing The component 5 pushes a plurality of magnetic pieces 1 arranged in parallel towards the baffle 4 and pushes the magnetic pieces 1 to the feeding position 2.1 in sequence under the limit of the baffle 4, and the bottom of the feeding position 2.1 is provided with an opening 6 A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com