Spring conveying roller, combined conveying roller, grooved roller and conveying assembly

A technology of conveying rollers and grooved rollers, which is applied in the field of spring conveying rollers, combined conveying rollers, grooved rollers and conveying components formed by them, which can solve the problems of inconvenient processing and inconvenient collection of materials, and achieve stable pleats, long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

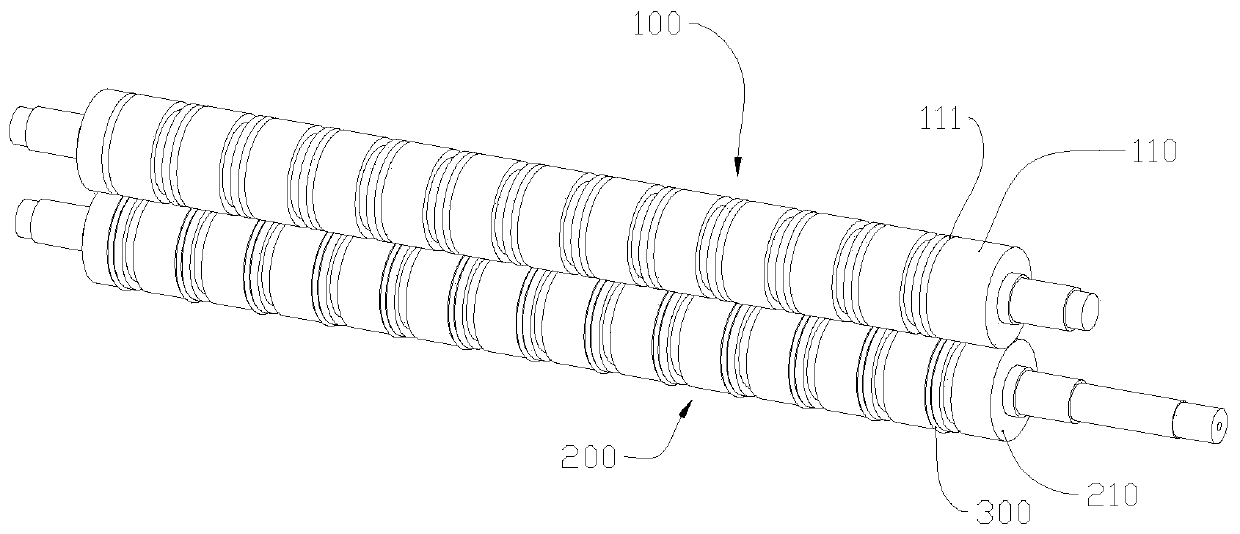

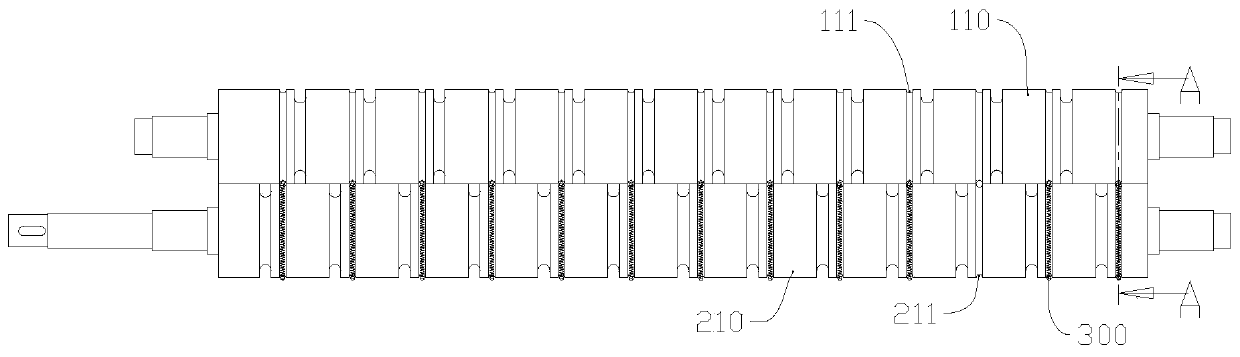

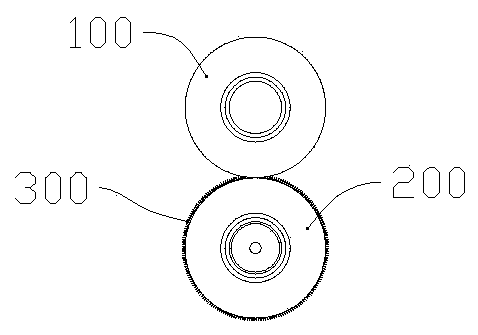

[0046] Embodiment 1 refers to figure 1 The structure of a spring conveying roller 100 shown in , includes a cylindrical roller body 110 and transmission shafts arranged on both end faces of the roller body 110, and the outer surface of the roller body 110 is provided with a plurality of first grooves 111, the second A groove 111 is an annular groove, which is arranged around the roller body 110 parallel to the radial plane of the roller body 110. The first groove 111 is provided with a spring bar 300 that coincides with the path of the first groove 111. The accompanying drawings figure 1 Restricted by the level of drawing, a hollow tube is used to replace the indicator spring bar 300, and it is best to combine Figure 2-Figure 4 To understand the spring bar 300 in , in addition, subject to drawing level and for the purpose of clearer presentation, Figure 2-Figure 4 The spring bar 300 in the figure has been simplified—it is shown in the form of a single line. In fact, the spr...

Embodiment 2

[0051] Embodiment 2 The difference between this embodiment and Embodiment 1 is that the ring groove is arranged on or inclined to the radial plane of the roller body 110, that is, in this embodiment, the first groove 111 is an inclined groove, correspondingly, The first groove 111 in the first embodiment is a straight groove.

Embodiment 3

[0052] Embodiment 3 The difference between this embodiment and the above embodiments is that the first groove 111 is a spiral groove, which is used to protrude the effect of the spring bar 300 . The number of spiral grooves is preferably more than two and distributed in parallel. However, under parallel distribution, in order to make the roller body 110 rotate and convey the material 400, it is best to maintain the same force on the material 400 each time it passes. Spacing, try to make the spiral groove evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com