Motor vehicle lift

A technology for lifting platforms and vehicles, which is applied in the field of lifting platforms and can solve problems such as vehicle slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

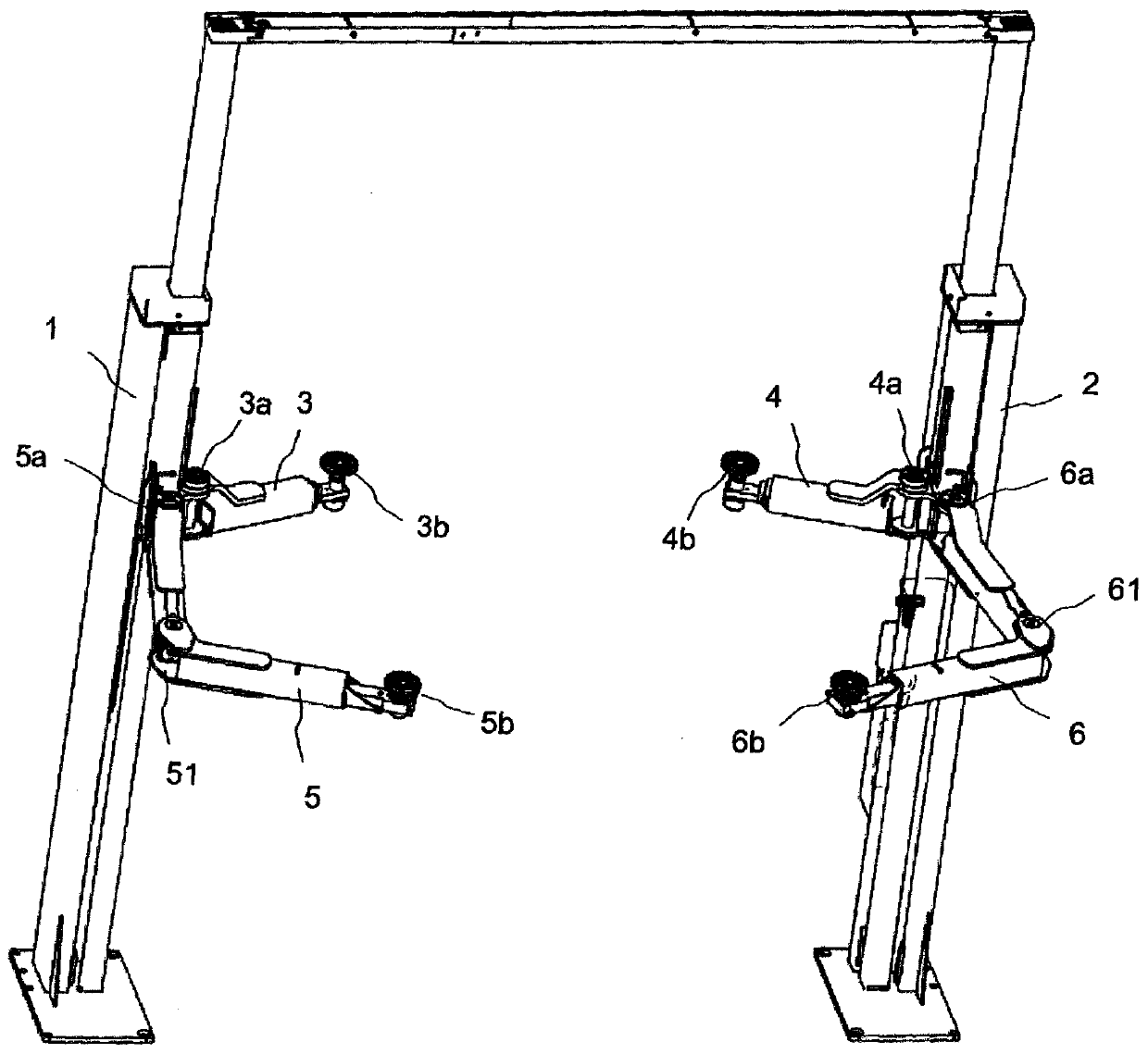

[0048] figure 1 A lifting platform including two lifting columns 1, 2 is shown, and two supporting arms 3, 5 and two supporting arms 4, 6 are pivotally hinged to each lifting column 1, 2 respectively. The carrying arms 3, 4, 5, 6 are vertically adjustable, that is, they can be raised and lowered. The lifting drive inside the lifting columns 1, 2 is carried out in a manner known per se, for example by a cylinder / piston assembly, by a screw or by a chain. The present invention is not limited to double-pillar lifting platforms, but can be used for all types of lifting platforms with carrying arms, such as four-pillar lifting platforms or column lifting platforms.

[0049] The carrying arms 3, 4 form a front carrying arm pair, that is, for raising the front half of the vehicle, while the carrying arms 5, 6 form a carrying arm pair for the rear half of the vehicle. The carrying arms 3 and 5 on the left vehicle side are arranged in a mirror-inverted manner relative to the carrying arm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap