Mask, preparation method thereof and evaporation method

A technology of mask plate and support part, which is applied in the directions of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of evaporation deviation and color mixing, etc., to ensure flatness, improve evaporation yield, avoid sagging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

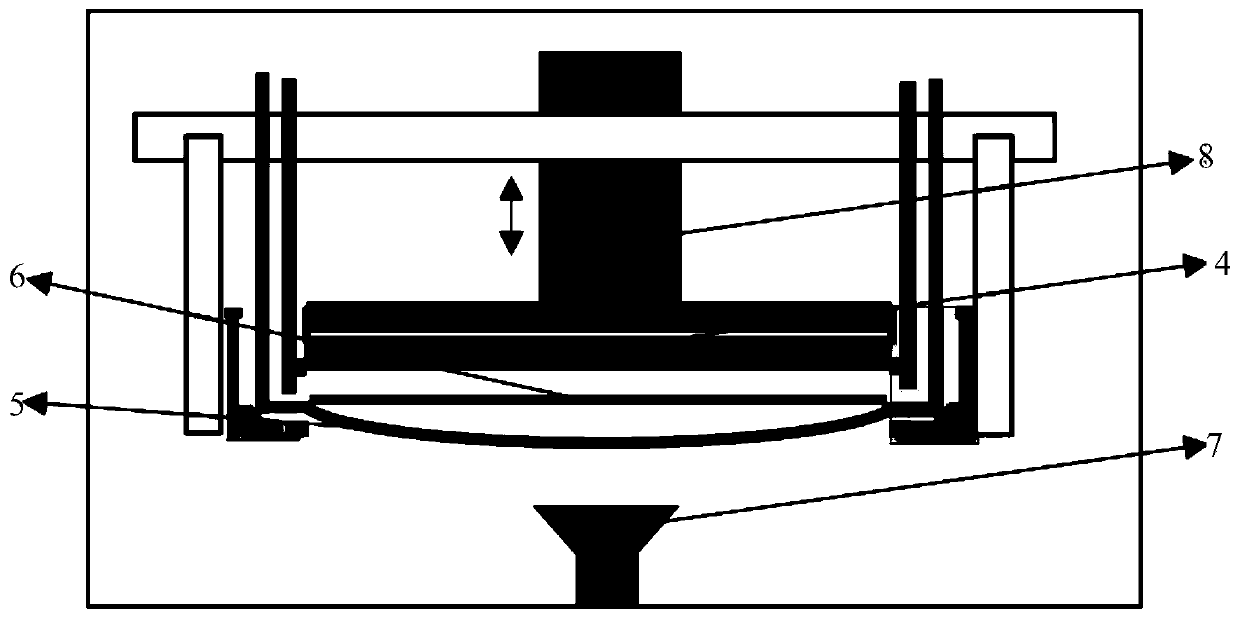

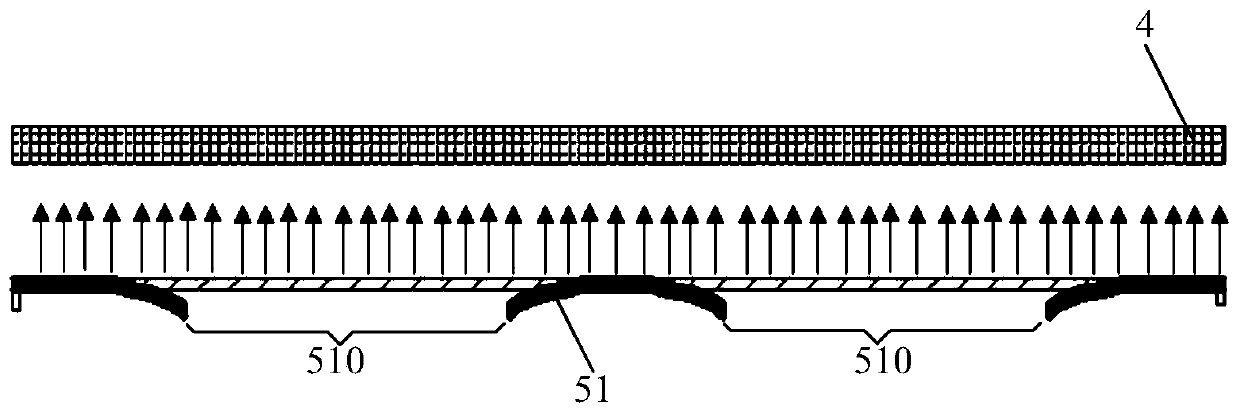

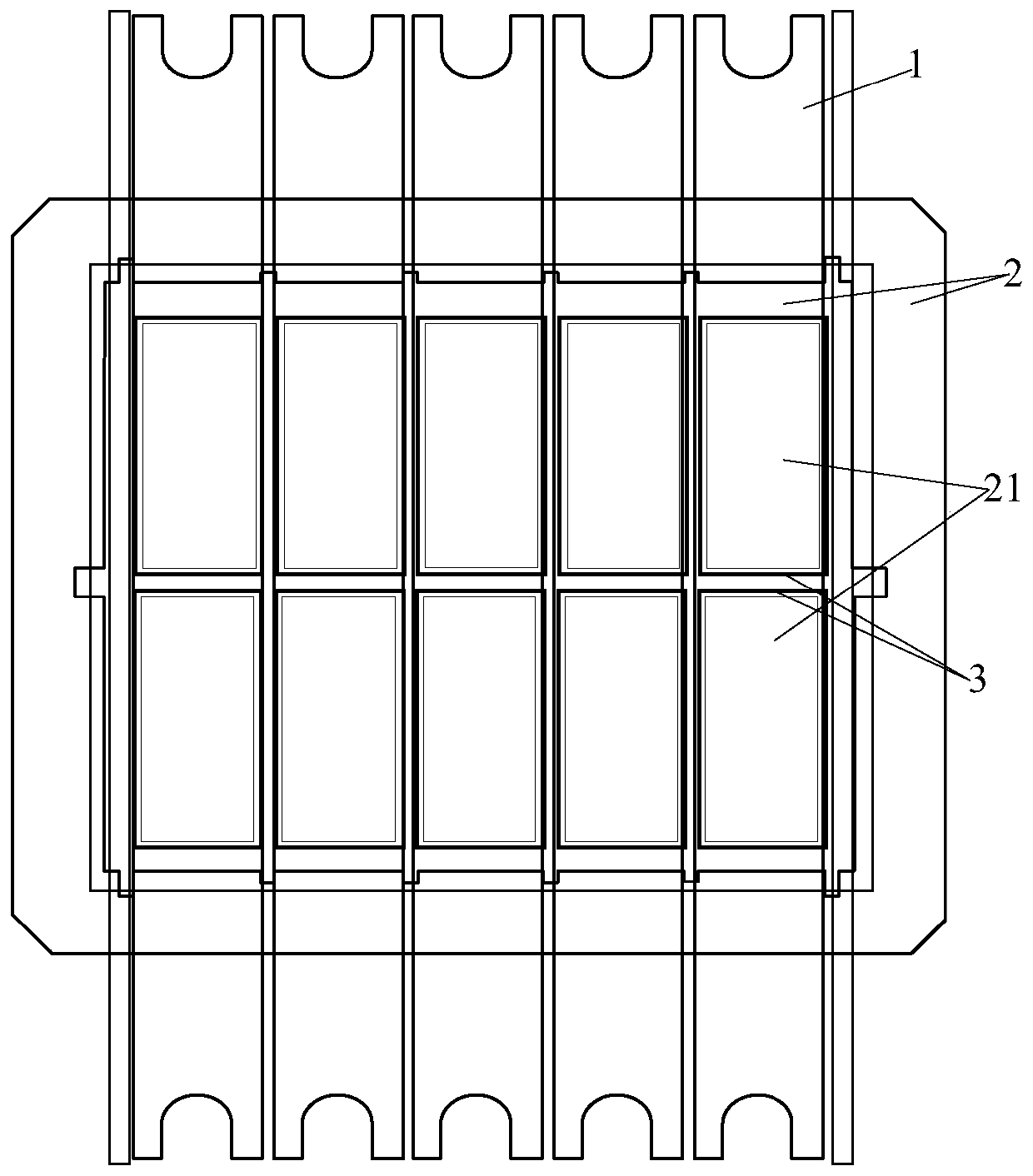

[0047] Based on the above technical problems of the mask, this embodiment provides a mask, such as image 3 As shown, it includes a main body part 1 and a support part 2, the main body part 1 is arranged on the support part 2, and the area for vapor deposition of the support part 2 includes a plurality of opening areas 21, and at least part of the opening areas 21 are provided at least part of the edge There is a magnetic adjustment part 3 configured to adjust the magnitude of the magnetic adsorption strength of the support part 2 at a corresponding position.

[0048] Among them, the main part 1 refers to the precision metal mask (Fine MetalMask, FMM) used to define RGB (red, green and blue) sub-pixels, and the support part 2 refers to the support mask (FMM) used to block the non-evaporation area and support the FMM. -Mask). The area used for vapor deposition of the main body part 1 refers to the area corresponding to the entire substrate to be plated on the main body part 1,...

Embodiment 2

[0060] This embodiment provides a mask plate. The difference from Embodiment 1 is that each opening area of the support part has at least one section of irregular edges with the same size and shape, and the irregular edges of each opening area are provided with Magnetic adjustment unit.

[0061] In this example, if Figure 5 As shown, each opening area 21 of the support part 2 has irregular rectangular edges with the same size and shape, and the edge lines of the four corners of each opening area 21 are arcs with the same curvature, and the four corner positions of each opening area 21 are set There are magnetic adjustment parts 3 with the same magnetic attraction strength.

[0062] Among them, since the four corners of each opening area 21 of the support part 2 are obviously less magnetic than other areas of the support part 2, the amount of sagging at the four corners of each opening area 21 is obviously different from other areas, affecting the main body flatness of the...

Embodiment 3

[0066] This embodiment provides a mask plate, which is different from Embodiment 1-2, such as Figure 8 As shown, the area for vapor deposition of the support part 2 includes at least two sub-areas, each sub-area is connected, and at least one opening area 21 is respectively arranged in each sub-area; the size of the opening area 21 in each sub-area is different. The shapes are similar; the irregular edges of the opening area 21 in each sub-area are respectively provided with magnetic force adjustment parts, the magnetic force of the magnetic force adjustment parts at different positions in the same sub-area is the same, and the magnetic force of the magnetic force adjustment parts in different sub-areas is the same. The adsorption strength is different.

[0067] Wherein, since the irregular edge of the opening area 21 in each sub-area on the support part 2 is obviously less than the magnetic adsorption strength in other areas of the support part 2, the irregular edge of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com