Drying separation device

A separation device and condensation chamber technology, applied in washing devices, dry cleaning equipment, textiles and papermaking, etc., can solve the problems of heavy operating burden, increase daily operating costs, affect business reputation and cleaning effect, etc., and achieve the effect of saving equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

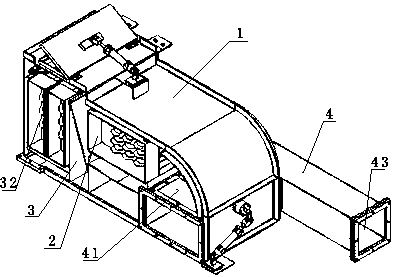

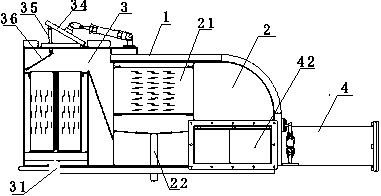

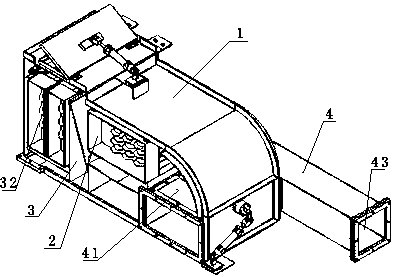

[0021] like figure 1 , 2 As shown, a drying and separating device can be integrated on the existing washing equipment, including a shell 1, a condensing chamber 2, a heating chamber 3, and an exhaust duct 4 are arranged in the shell, and the condensing chamber 2 and the heating chamber are 3 phases. Adjacent to the setting, the condensation chamber 2 communicates with the heating chamber 3,

[0022] A condenser 21 is installed in the condensation chamber 2, and a liquid outlet 22 is arranged at the bottom of the condensation chamber, and the liquid outlet 22 is connected with the dry cleaning liquid tank of the washing equipment through a pipeline.

[0023] The lower part of the heating chamber 3 is provided with an outlet 31, and the outlet 31 communicates with the front of the outer cylinder of the washing equipment through a pipeline. There is an air inlet 33 on the top of the chamber, and an air inlet door 34 is hinged on one side of the upper part of the air inlet 33. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com