Assembly type intelligent vibration isolator

A vibration isolator and assembled technology, which is applied in the field of rail transit, can solve the problems of inability to absorb, convert, and utilize energy, and achieve the effects of improving work safety and durability, stable state, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

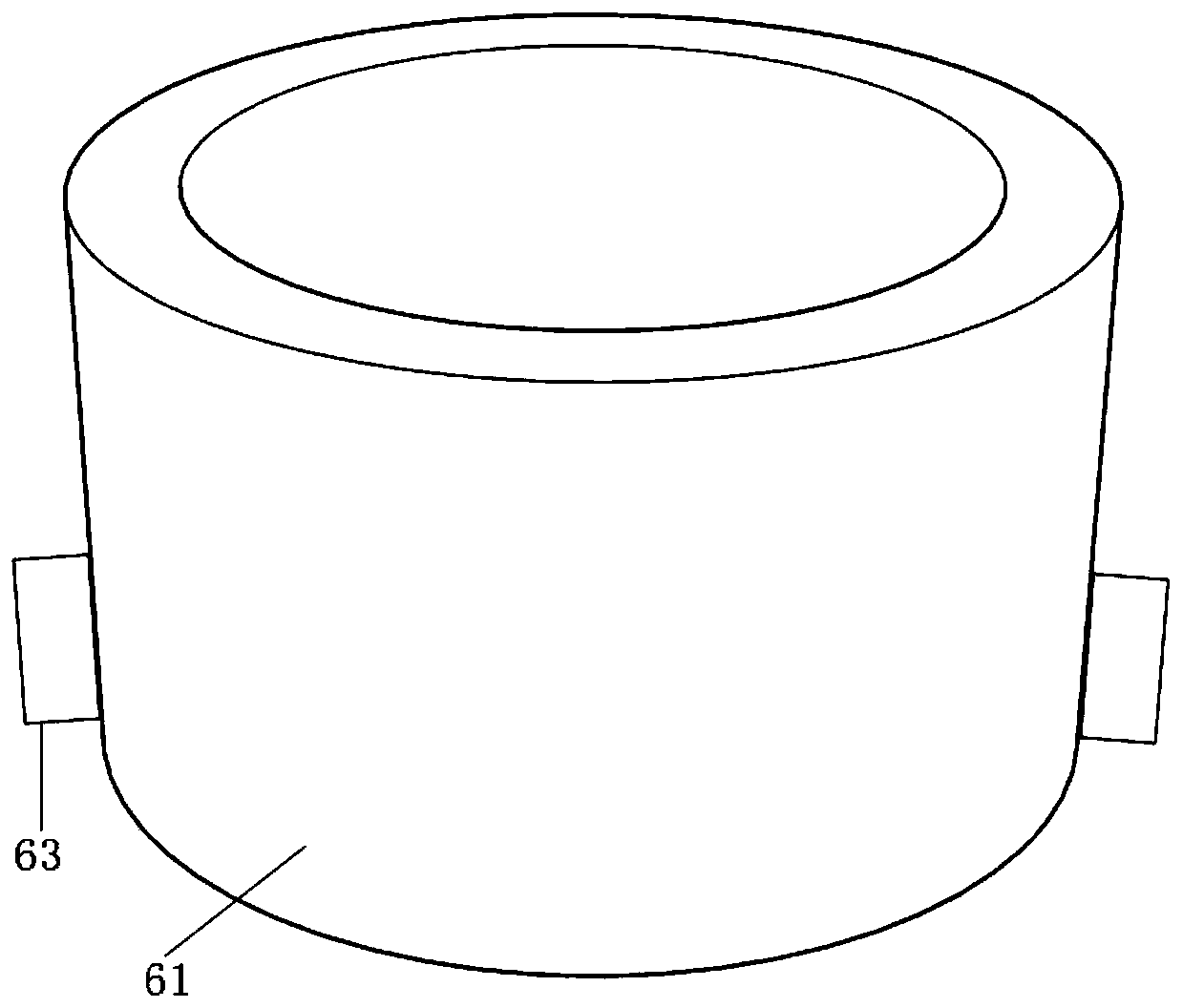

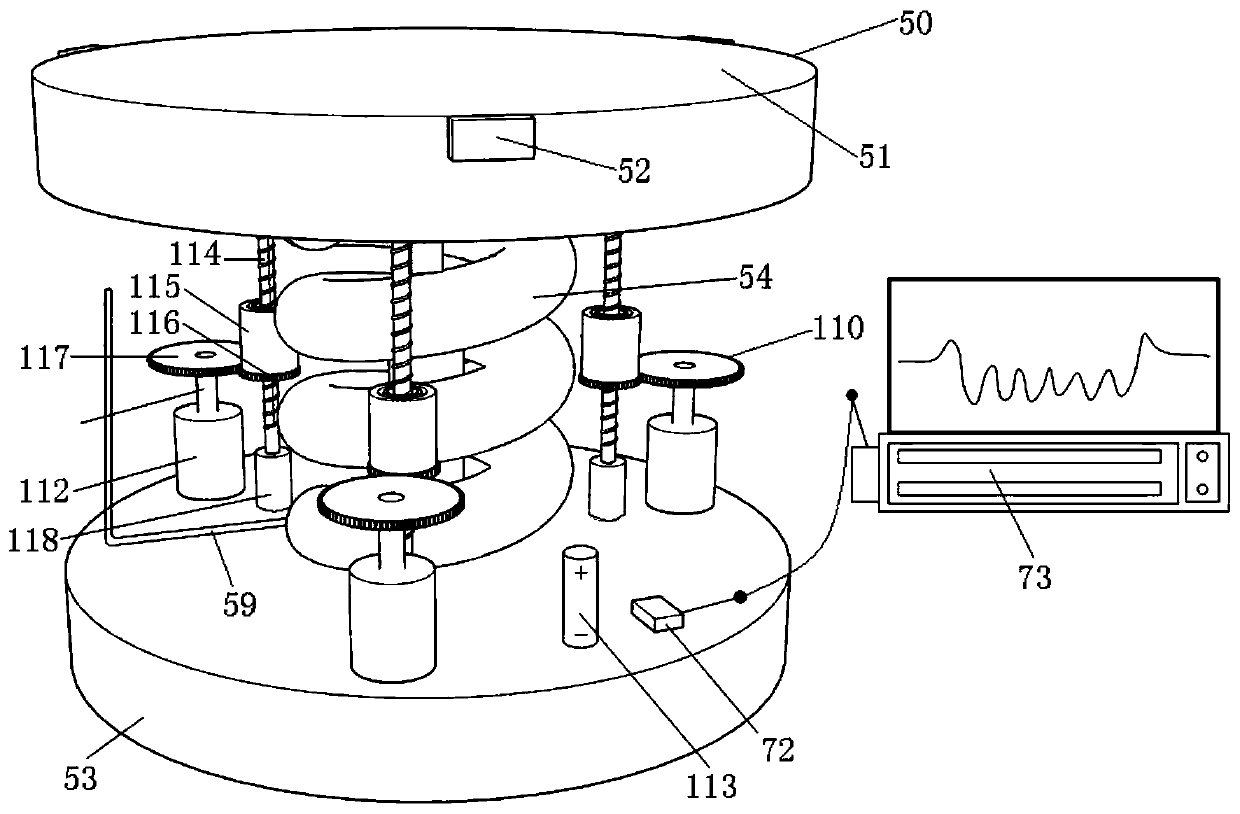

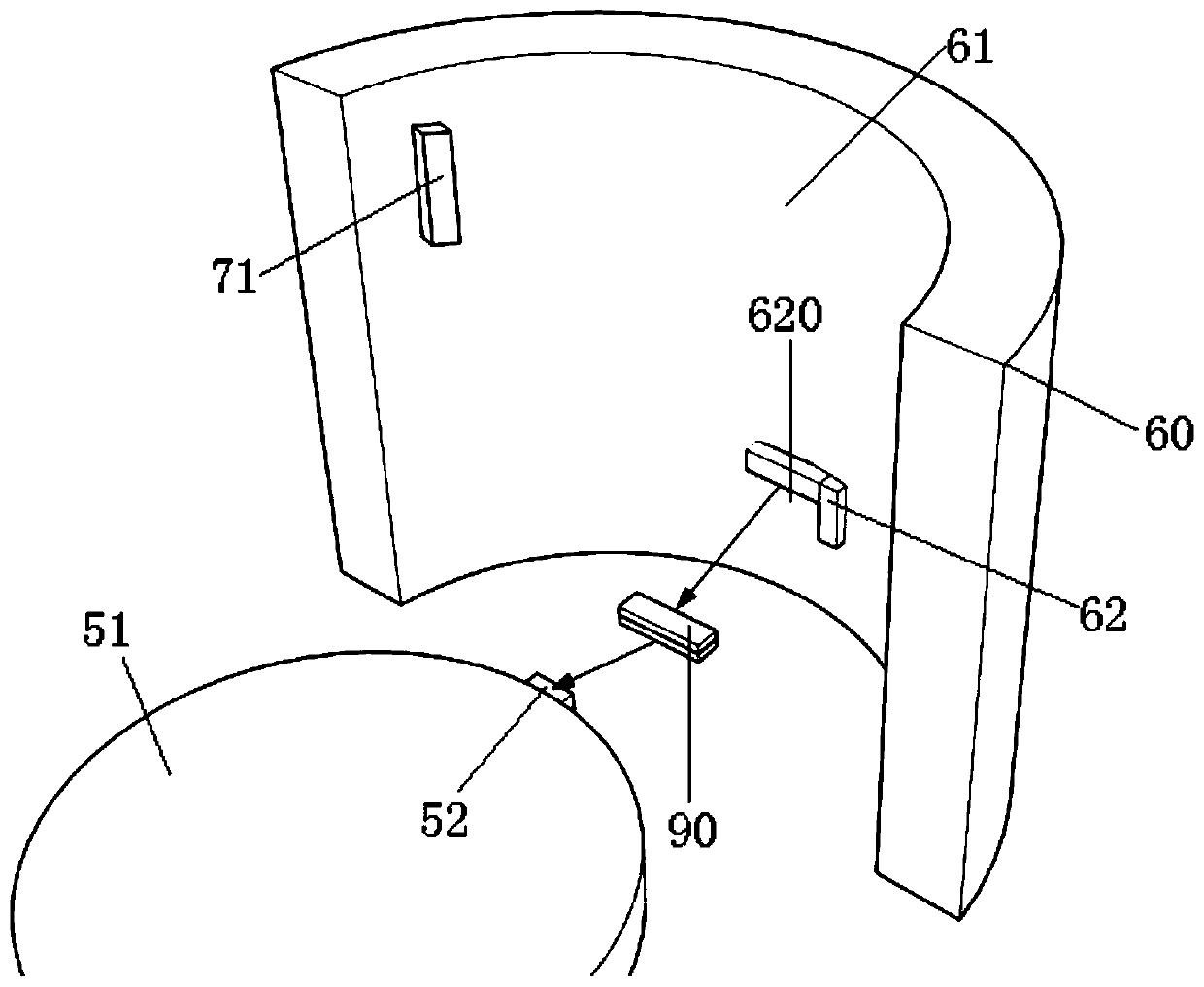

[0027] refer to Figure 1-Figure 3 , the preferred embodiment of the present invention provides an assembled intelligent vibration isolator, which is used to be vertically supported on the track foundation and the upper end is fixedly connected with the floating plate track, so as to vertically float the floating plate track. The prefabricated intelligent vibration isolator includes: an inner cylinder assembly 50 and an outer cylinder assembly 60 that are fitted inside and outside along the vertical direction, the upper end of the outer cylinder assembly 60 is integrally formed with the floating plate track, and the inner cylinder assembly 50 is In the outer cylinder assembly 60, and the lower end of the inner cylinder assembly 50 protrudes from the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com