Railway ballast bed rock ballast recovery device

A recovery device and railway track technology, which can be applied to roads, tracks, ballast layers, etc., can solve the problems of ballast slag dispersion, a large amount of manpower, and difficult recycling, so as to reduce labor intensity, expand the area of cultivated land, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

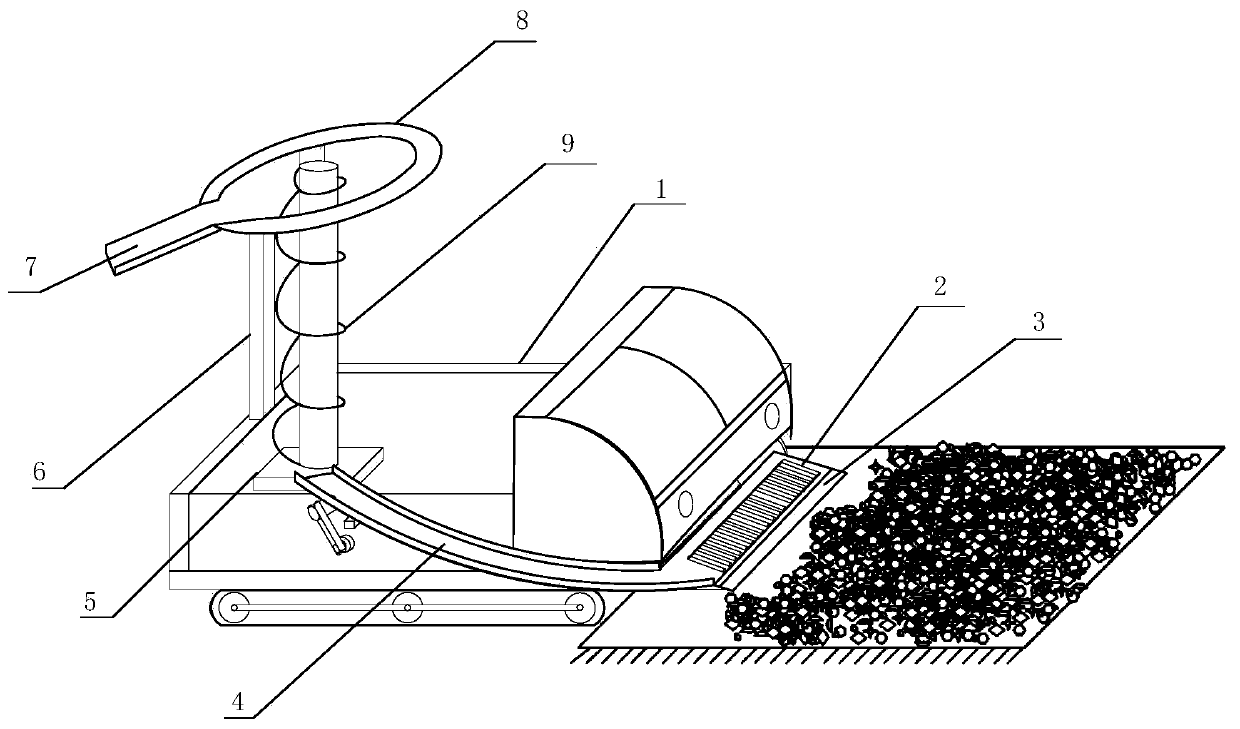

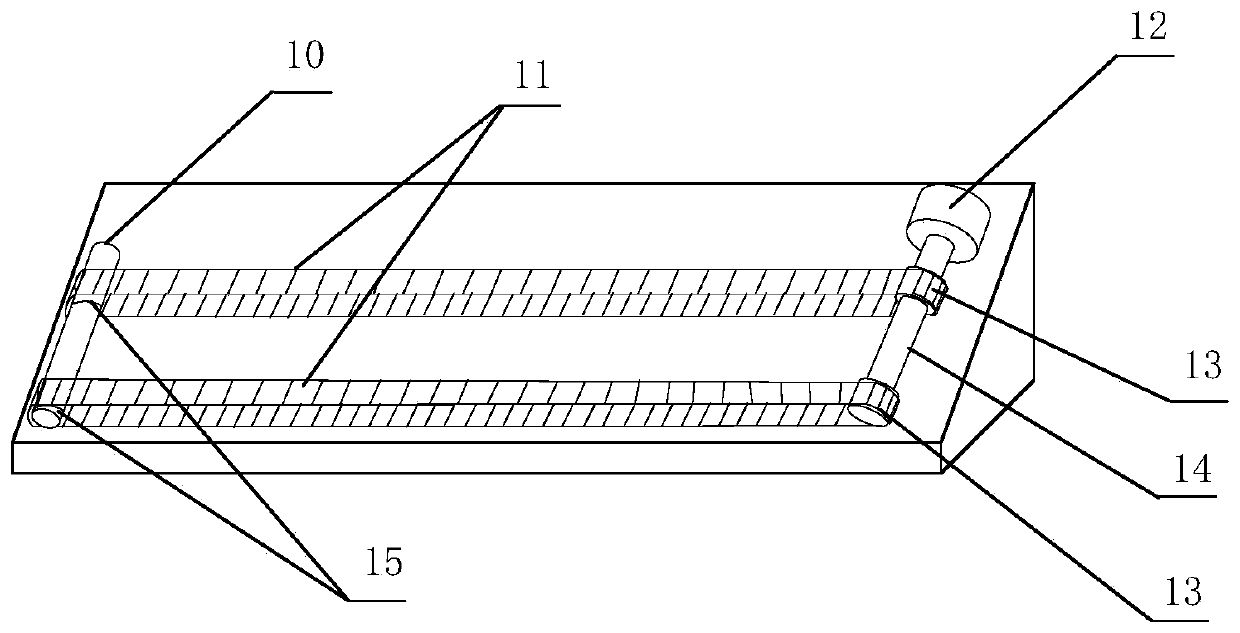

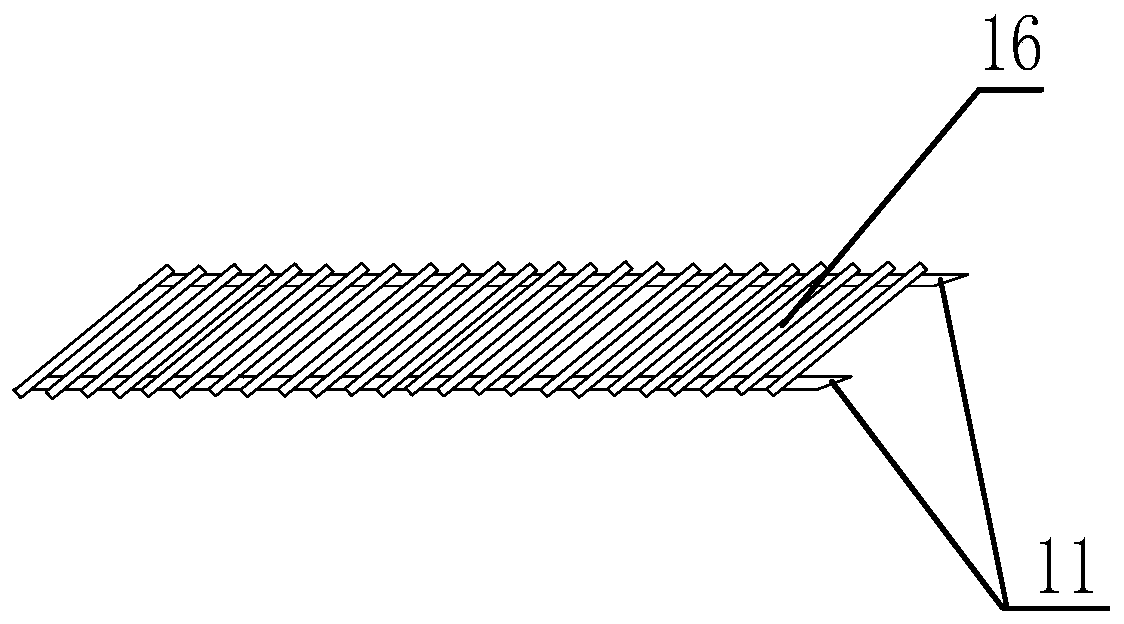

[0028] see Figure 1 to Figure 7 Shown is a railway track bed gravel recovery device in the present invention, comprising a crawler vehicle 1, a first conveying device 2, a bucket 3, a second conveying device 4, a rotary table 5, a support frame 6, a discharge port 7, Annular bucket 8, spiral blade 9.

[0029] Such as figure 1 As shown, the bucket 3 is installed in front of the crawler vehicle 1 for scooping up gravel on the railway track bed, and the first conveying device 2 is installed in the bucket 3 for transporting the gravel scooped up by the bucket 3 , the second transmission device 4 is installed on the side of the crawler vehicle 1, and is used to transmit the gravel on the first transmission device 2 to the compartment of the crawler vehicle 1, the rotary table 5 is installed in the compartment of the crawler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com