A method for adjusting the variable stiffness of an hourglass spring through a hard stop and the hourglass spring

An hourglass spring and variable stiffness technology, which is applied to spring components composed of several springs, springs, springs/shock absorbers, etc., can solve the problems of rubber cracking, inability to adjust stiffness, and easy wrinkling of rubber profiles. The effect of achieving high load-carrying capacity, low lateral stiffness, avoiding wrinkles and the risk of rubber cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

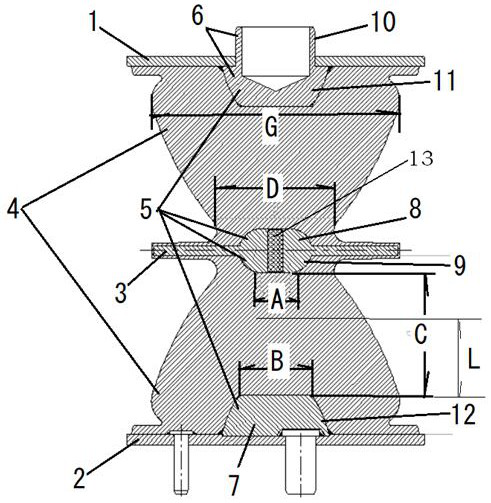

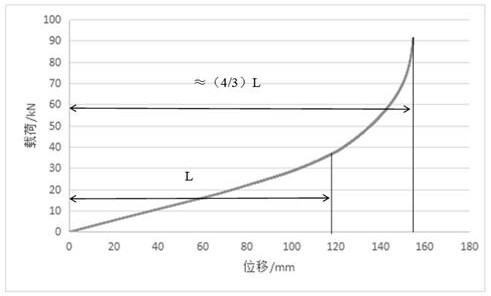

[0043] by attaching figure 2 It can be seen that the present invention relates to an hourglass spring that realizes the method for adjusting the variable stiffness of the hourglass spring through a hard stop, including an upper end plate 1, a lower end plate 2, an intermediate support plate 3 and an hourglass-shaped rubber body 4; the hourglass-shaped rubber body The shape of 4 is hourglass-shaped, and the hourglass-shaped rubber body 4 is integrally vulcanized together with the lower surface of the upper end plate 1 and the upper surface of the lower end plate 2, and the middle support plate 3 is wrapped and vulcanized on the middle part of the hourglass-shaped rubber body 4 to form a belt. The hourglass spring of the intermediate partition; the inside of the hourglass-shaped rubber body is all solid rubber, and hard stoppers 5 are respectively set on the upper end plate 1, the lower end plate 2 and the middle support plate 3 of the hourglass rubber spring, through the upper ...

Embodiment 2

[0051] The principle of the second embodiment is the same as that of the first embodiment, except that the structure is slightly different. The hourglass rubber spring adopts an upper end plate combination, a lower end plate combination, a middle support plate and rubber, and an upper end plate combination and a lower end plate of the rubber. The plate combination is respectively connected with a hard stop, and the hard stop can be connected to the upper and lower plates by welding; the middle support plate is connected to the middle part of the rubber; and there is a hard stop in the middle of the middle support plate; the rubber vulcanized body has a small middle diameter 1. Hourglass structure with large diameters at both ends; the ratio of the minimum external diameter of the middle part of the rubber to the maximum diameter of both ends of the rubber is less than or equal to 1 / 2, and the diameter of the rubber cannot be smaller than the diameter of the hard stop of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com