Variable stiffness adjusting method of motor mount and motor mount thereof

An adjustment method and variable stiffness technology, applied in the direction of electric power devices, power devices, mechanical equipment, etc., to achieve the effect of ensuring vibration isolation, ensuring reliability and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

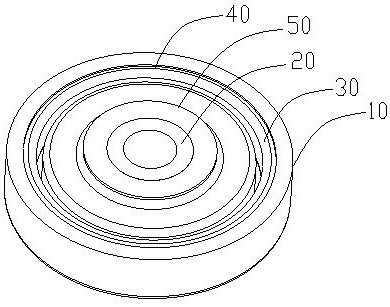

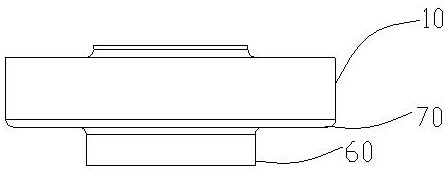

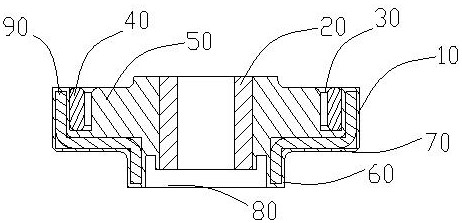

[0037] like figure 1 - Figure 4 As shown, this embodiment redesigns the structure of the motor mount according to different requirements for the lateral stiffness of the motor mount in actual application conditions. Specifically, the motor mount includes a rigid structure 90, and the rigid structure 90 includes a set of The stopper portion 10 at the open end of the motor suspension and the mounting portion 60 on the side away from the open end of the motor suspension; the stopper portion 10 and the mounting portion 60 are connected by the bearing portion 70 ; the rigid structure 90 is stepped as a whole. The mandrel 20 extends from the stopper portion 10 into the mounting portion 60 .

[0038] In this embodiment, a stopper portion 10 is added to the motor suspension structure, and a variable stiffness adjusting slot 30 is added at the stopper portion 10 , which can effectively adjust the stiffness of the elastic body 50 . The motor mount can choose an elastic material with ...

Embodiment 2

[0047] This embodiment discloses the variable stiffness adjustment method of the motor mount of Embodiment 1. In this embodiment, a gap portion 80 is provided between the bottom surface of the mounting portion 60 and the bottom plane of the mandrel 20 . When the entire suspension structure is press-fitted, a part of the elastic body 50 can be deformed and press-fitted into the void portion 80, so that the preloading effect of the entire upper and lower cushion blocks is good. The design of the gap 80 makes the height difference between the bottom of the mandrel 20 and the mounting part 60 before the product is installed, so that a concave space is formed in the mounting part 60; after installation, the height between the bottom of the mandrel 20 and the mounting part 60 The difference is eliminated, that is, a pre-stress is provided to the product to improve the service life of the product.

[0048] The variable stiffness adjustment method of the motor suspension of this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com