High-pressure container protection structure

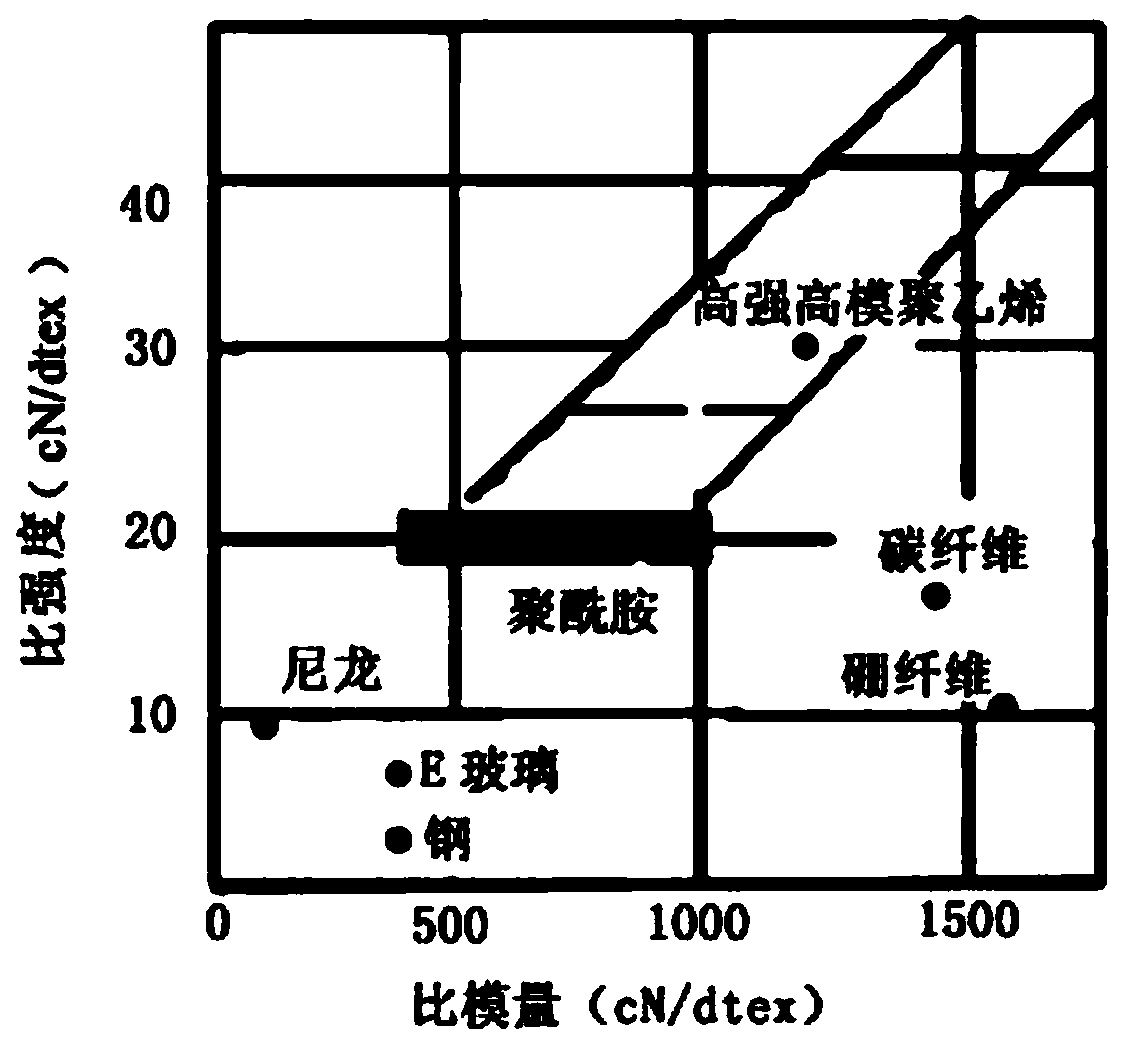

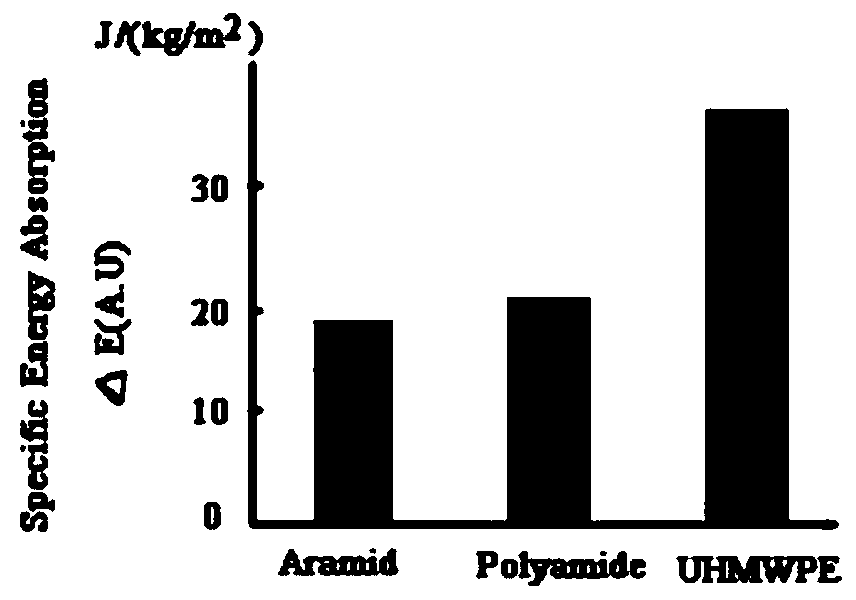

A technology of protective structure and protective frame, which is applied to the installation device of container structure, container filling method, container discharge method, etc., can solve the problem of isolation of inoperable personnel from products and high-pressure gas cylinder groups, leakage and high-speed ejection, personnel Equipment damage and other problems, to achieve the effect of stable protective structure, impact resistance, high and low temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

[0024] The invention adopts a movable and assembled isolation protection room, including an isolation protection frame and a movable shield structure. The isolation frame can be a shelf to form a room, and then the movable shield structure can be mounted on the isolation frame in a suitable manner. In the present invention, the isolation protection frame can be any suitable structure capable of installing a movable shield structure, which will not be described in detail here.

[0025] In some embodiments, the shield structure has a height less than 1.6m and a width greater than or equal to 0.9m. In some embodiments, the nozzle is protected by a movable shield, which can isolate the nozzle from the staff. On the one hand, the operator is prevented from being hurt by the high-pressure gas ejected from the nozzle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com