Electric boiler not likely to generate limescale and working method thereof

A technology for electric boilers and scale, applied in the field of electric boilers, can solve the problems of high cleaning difficulty, inconvenient cleaning, and long time consumption, and achieve the effect of good working stability and good heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

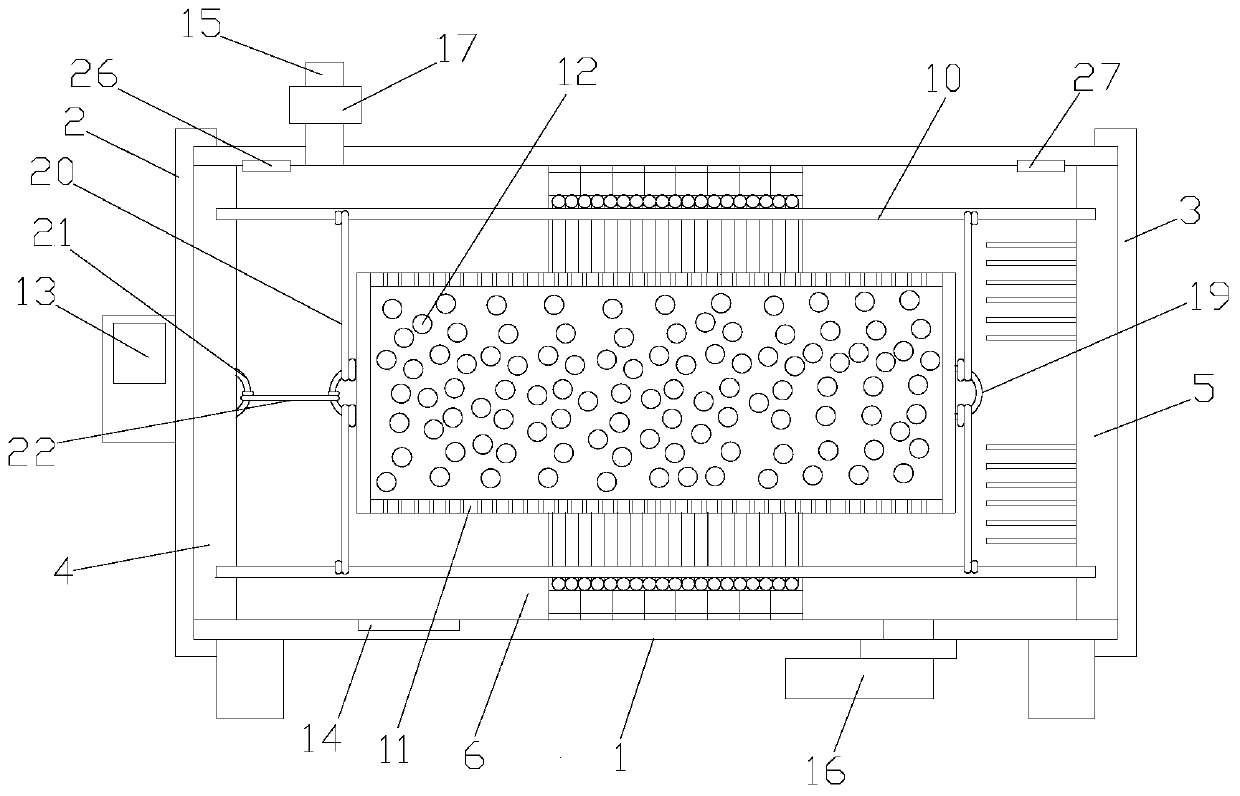

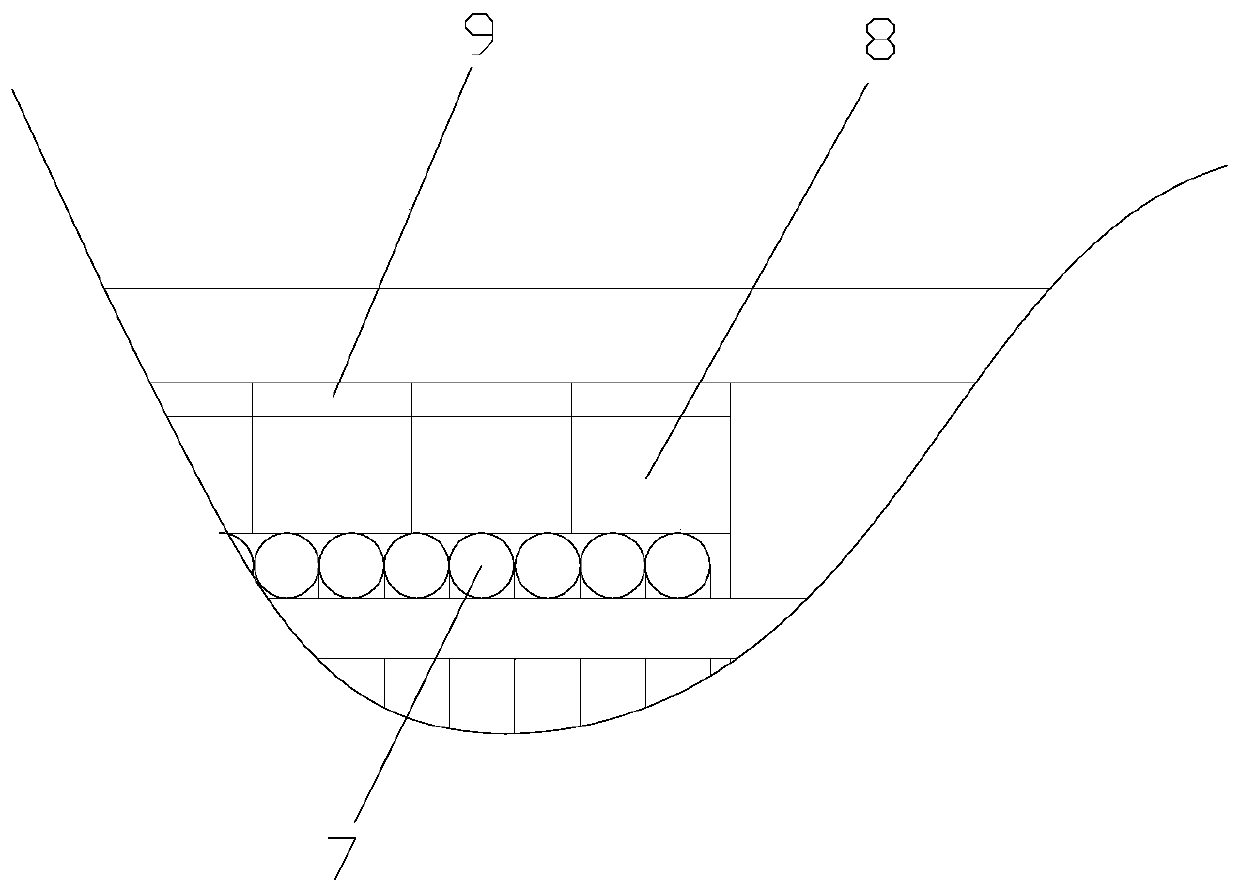

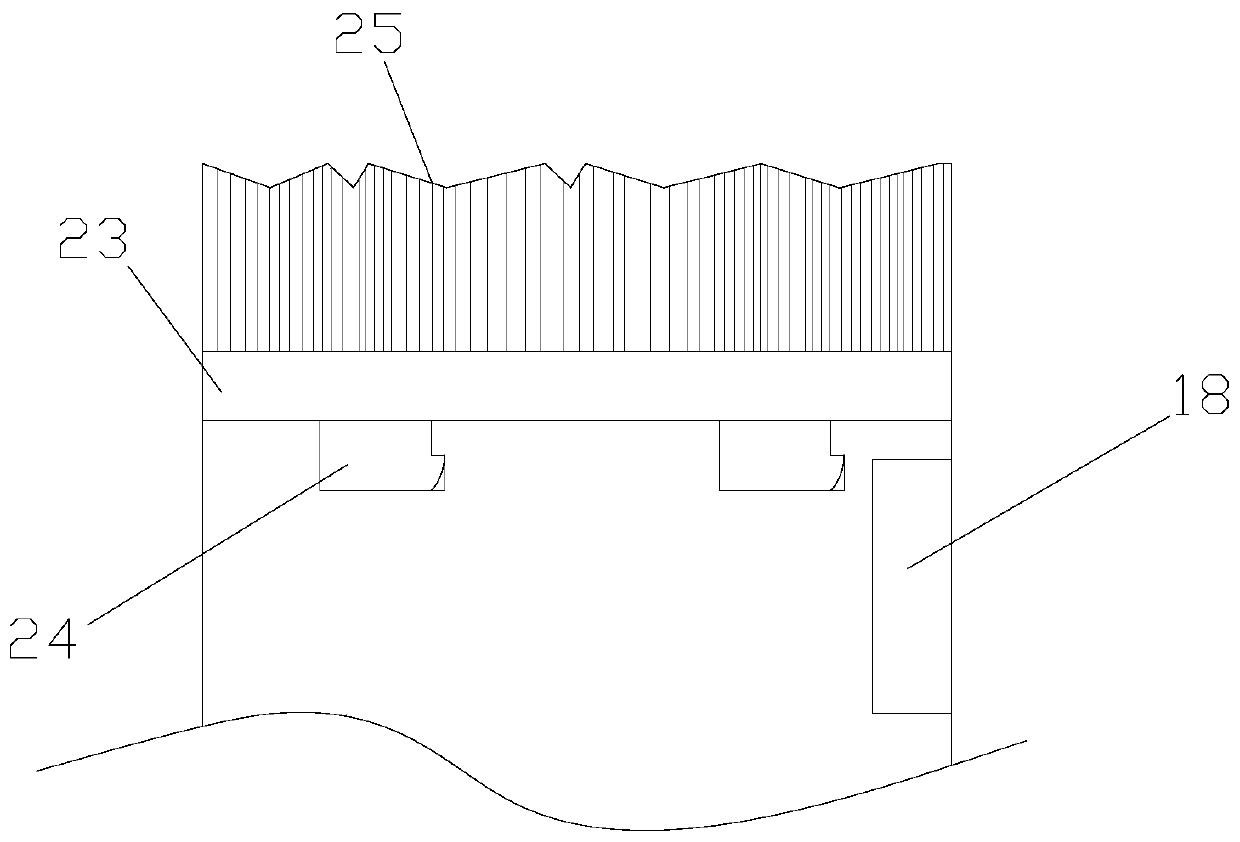

[0031] Such as Figure 1-3As shown, an electric boiler that is not easy to grow scale includes a heat insulation cylinder 1, a left end cover 2 and a right end cover 3, and the backs of the left end cover 2 and the right end cover 3 are respectively provided with a first electric heating iron 4 and a second electric heating iron 5. Both the left end cover 2 and the right end cover 3 are fixedly connected to the heat insulation cylinder 1, a heating cavity 6 is formed between the heat insulation cylinder 1, the left end cover 2 and the right end cover 3, and the first electric heating iron 4 and The second electric heating irons 5 are all located in the heating chamber 6, and the heating chamber 6 is provided with a temperature control spring 7 and a movable ring 8, and the temperature control spring 7 is inserted into the movable ring 8 and is fixedly connected with the movable ring 8. The temperature control spring 7 drives the movable ring 8 to move in the heating chamber 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com