Method for testing damage of star sensor detector caused by strong light irradiation

A star sensor and radiation damage technology, applied in the field of star sensors, can solve problems such as affecting the attitude measurement accuracy of the star sensor, insufficient complex lighting environment, system failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

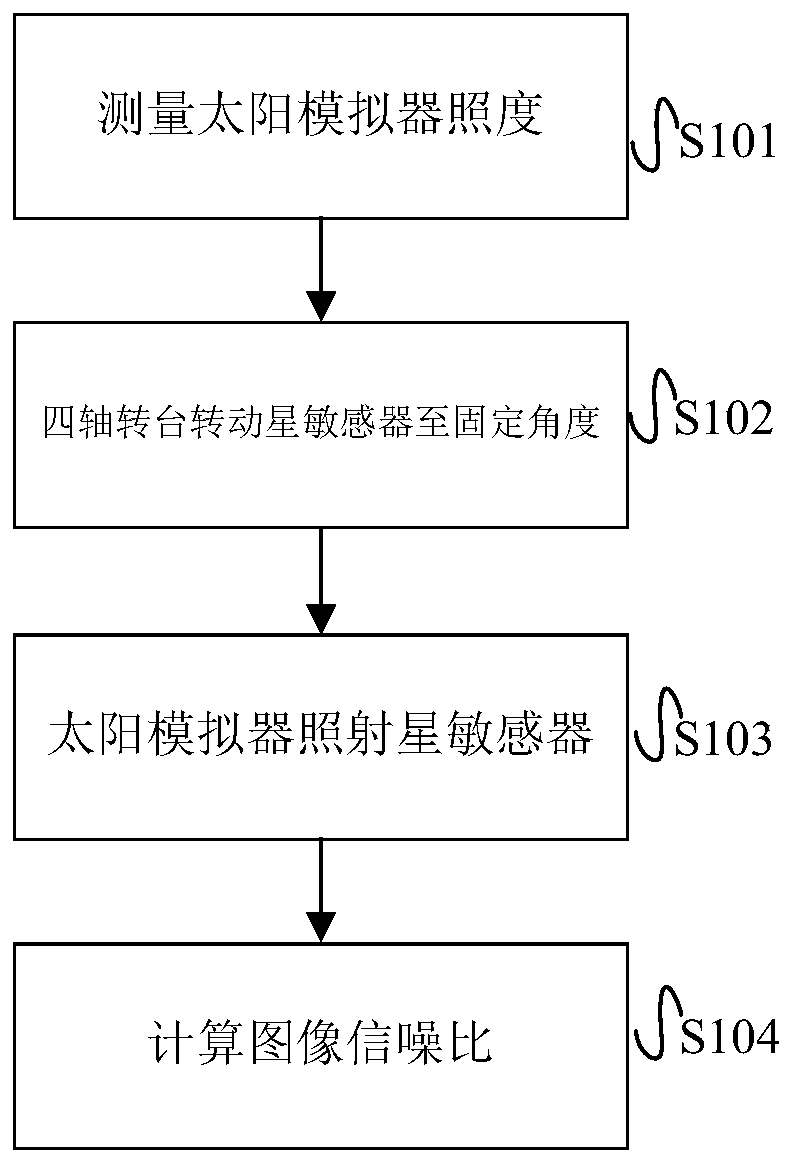

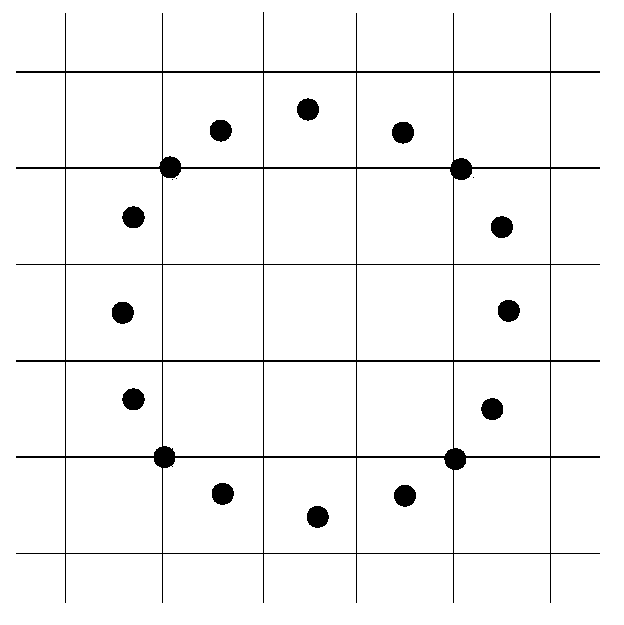

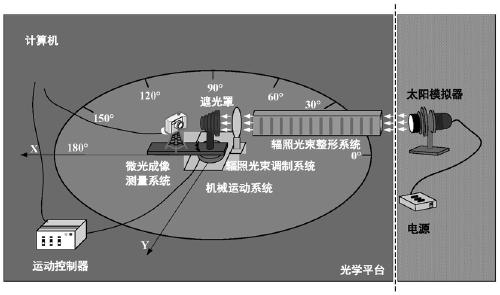

[0038] 1. Install the low-light imaging measurement system on a high-precision four-axis turntable, turn the turntable to a fixed position, and determine the angle between the optical axis between the solar simulator and the low-light imaging measurement system, so that the light emitted by the solar simulator can be fixed The angle is incident through the radiation beam shaping system, according to figure 2 At the point shown, rotate the four-axis turntable to measure the illuminance of the solar simulator at different points. Afterwards, the illuminance of the solar simulator is obtained by comprehensive calculation according to the illuminance of the solar simulator at different points, and the irradiance at the exit end of the solar simulator is measured.

[0039] 2. Install the star sensor on a high-precision four-axis turntable, and determine the angle between the optical axis between the solar simulator and the star sensor again, so that the light emitted by the solar ...

Embodiment 2

[0043] 1. Press image 3 As shown in , fix the low-light measurement system on the four-axis turntable, turn it at a certain angle, turn on the solar simulator, press figure 2 Rotate the four-axis turntable as shown to make the star sensor measure the illuminance of the solar simulator at different points, and calculate the illuminance of the solar simulator comprehensively according to the illuminance of the solar simulator at different points.

[0044] Two, press Figure 4 As shown, remove the low-light measurement system, install the star sensor, and make sure that the angle between the optical axis of the star sensor and the solar simulator is 5°.

[0045] 3. Turn on the solar simulator and irradiate the solar simulator for 5 minutes.

[0046] 4. Turn off the solar simulator and take a black picture of the star sensor, such as Figure 6 shown.

[0047] 5. Calculate the signal-to-noise ratio of the area irradiated by strong light in image 6. The signal-to-noise ratio in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com