Semantic-based industrial production equipment predictive maintenance system

A technology for industrial production equipment and equipment maintenance, which is applied in the combined field of Semantic Web and Industrial Internet of Things, can solve the problems of unsatisfactory inference efficiency of traditional rule reasoning, low degree of intelligence, lack of semantics in equipment monitoring data, etc., to achieve Improve production efficiency, facilitate maintenance management, and assist maintenance management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred implementation cases of the present invention will be described in detail below in conjunction with the accompanying drawings.

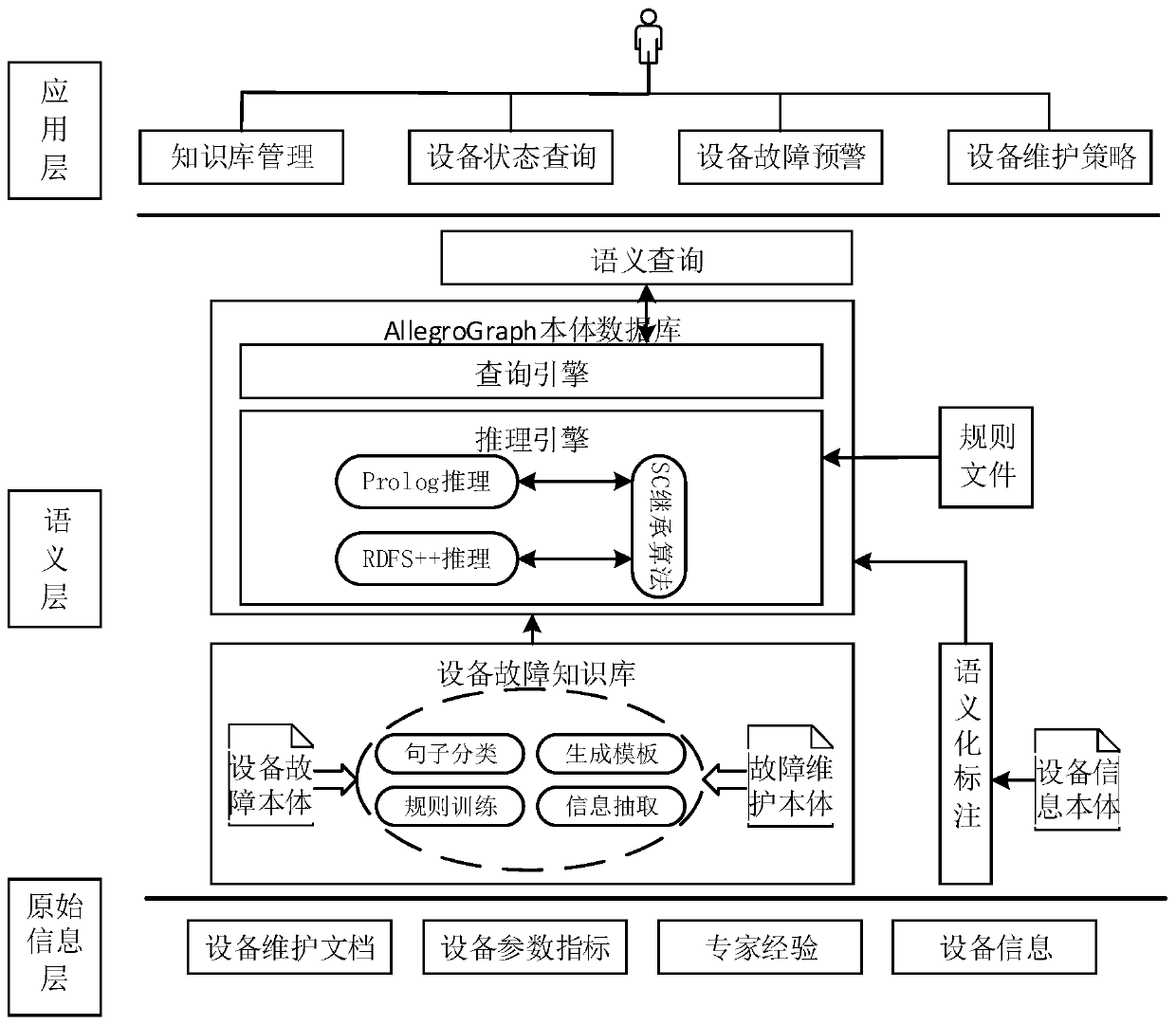

[0031] Such as figure 1 As shown, the system architecture diagram of semantic-based predictive maintenance strategy for industrial production equipment, the architecture diagram includes the following parts:

[0032] (1) The original information layer. The original information layer includes equipment maintenance documents, equipment parameter indicators, expert experience, and equipment information. The equipment information includes two parts. One is the equipment operation data collected by sensors in real time, including temperature, pressure, speed, etc.; the other is the basic information of equipment spare parts , including the spare part name, model, serial number, etc.

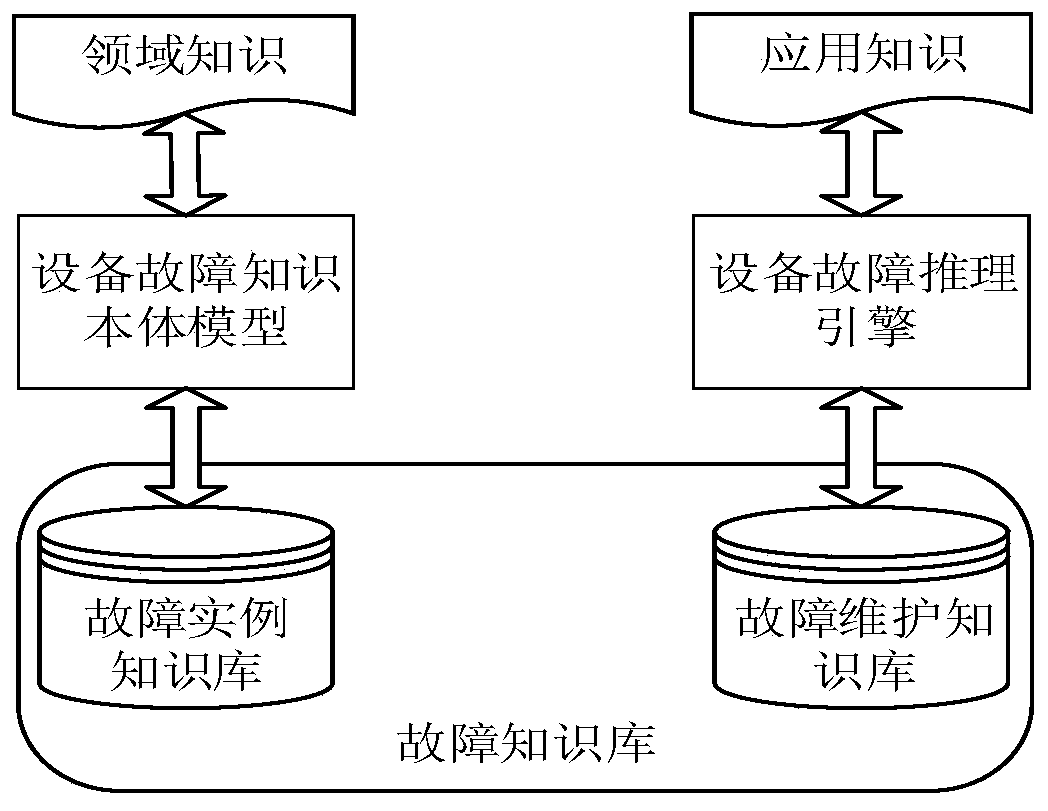

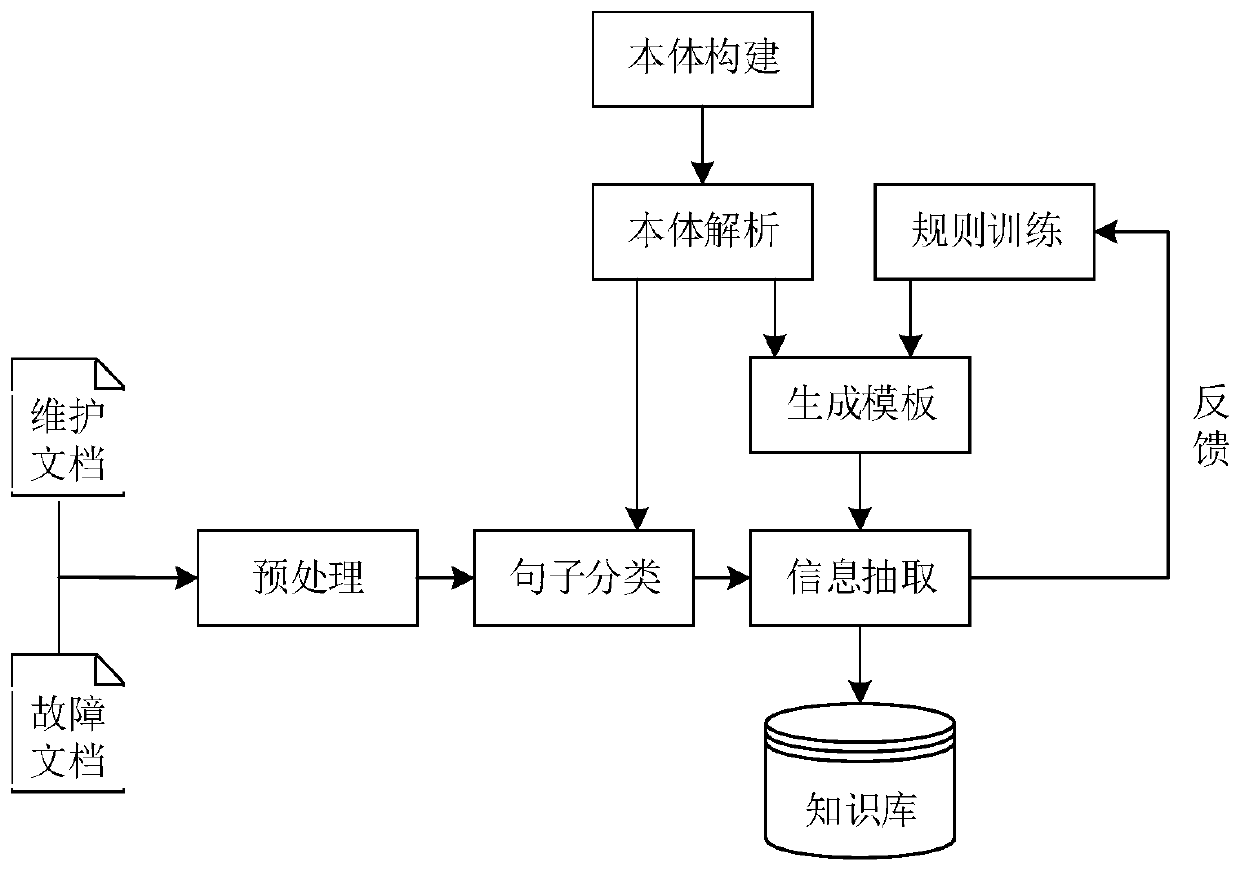

[0033](2) Semantic layer. The semantic layer includes device information ontology model, device fault knowledge base module, device information seman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com