A disc-type hub drive motor

A hub-driven, disc-type technology, applied in the field of electric motors, can solve the problems of low heat dissipation efficiency, small contact area between copper tubes and windings, limiting motor output power, etc., and achieve the effect of improving heat dissipation efficiency, reasonable structure design, and improving output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The traditional disc hub motor has a motor weight of 26kg, a peak power of 55kW, an external dimension of Φ240mm×140mm, a peak torque of 120Nm, and a motor power density of 2.12kW / kg.

[0034] The other structures of the disc hub motor in this embodiment are consistent with the existing disc hub motor, only the cooling system is improved, the motor weighs 22kg, the peak power is 135kW, the peak torque is 300Nm, and the power density of the motor is 6.1kW / kg.

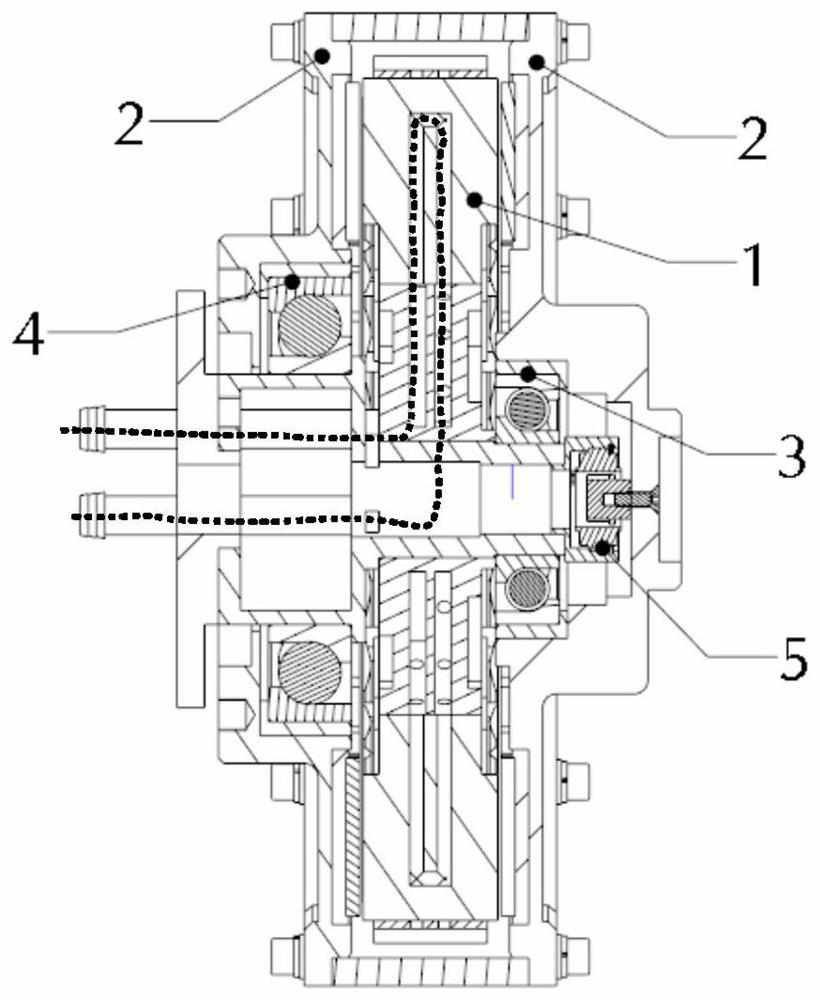

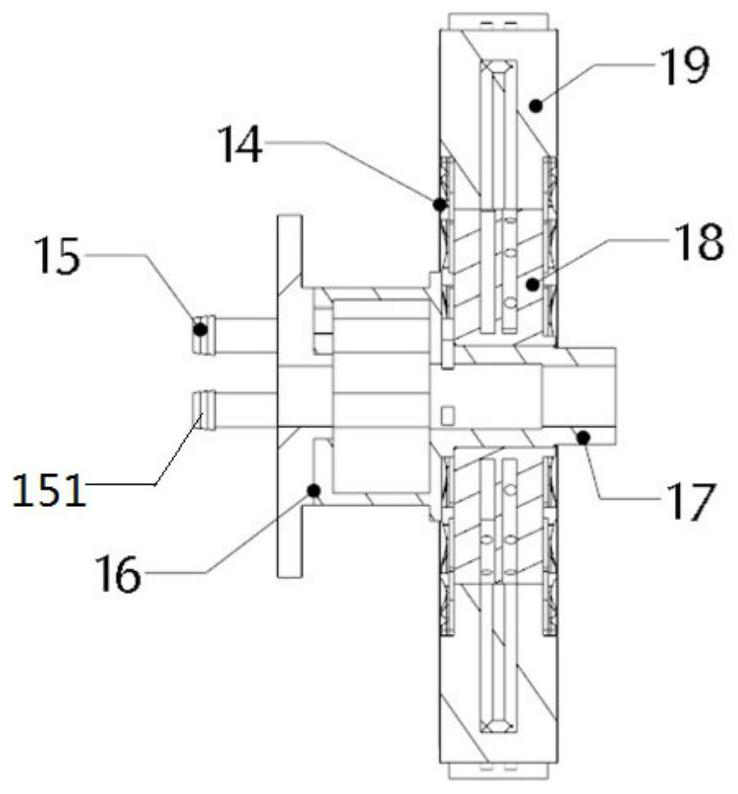

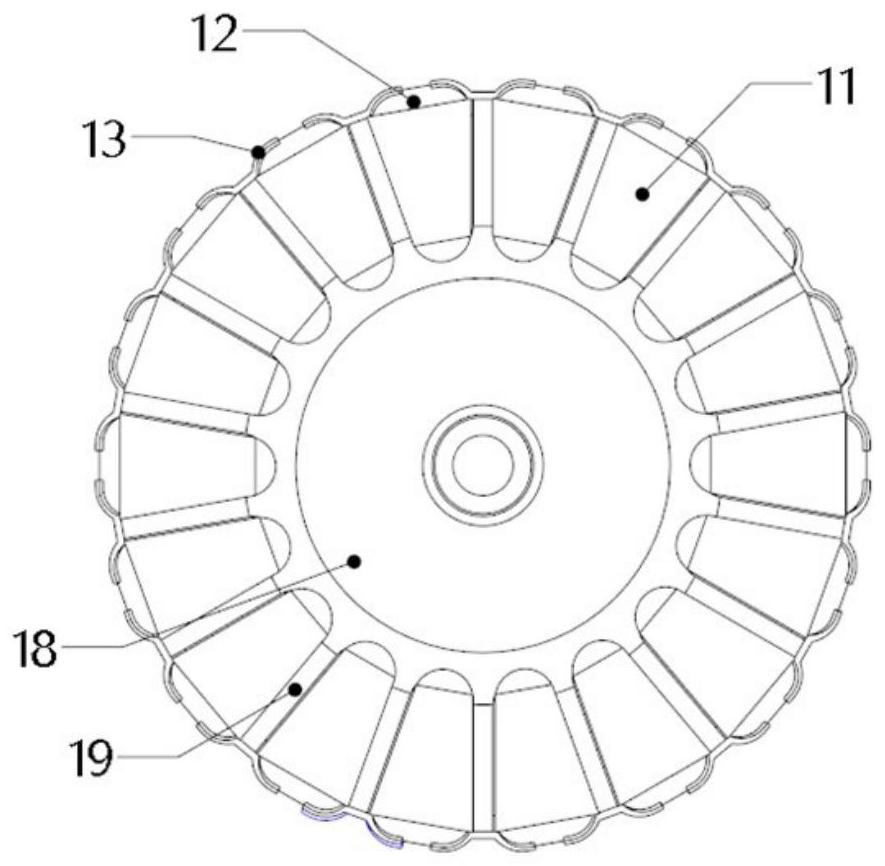

[0035] see figure 1 , a disc hub drive motor includes a stator assembly 1 and a rotor assembly 2; the stator assembly 1 includes an annular stator holder, a number of stator units, a fixed shaft 17 and a shaft-shaped flange 16; see image 3 , each stator unit includes a stator core 11 , a stator coil winding 12 and a fixed clip 13 . see Figure 4 , the rotor assembly 2 includes a front flange 21 , a yoke 22 , a permanent magnet 23 , a housing 24 and a rear flange 25 . When in use, the stator assembly 1 is fixe...

Embodiment 2

[0044] The other structure of the disc hub motor in this embodiment is consistent with the traditional disc hub motor, only the cooling system is improved, the structure is the same as that of Example 1, but the size is different; the weight is 15kg, the peak power is 92kW, and the power density of the motor is 6.1kW / kg .

[0045] A traditional disc hub motor without an improved structure and with the same structure in other parts has a motor weight of 17kg, a peak power of 48kW, and a motor power density of 2.8kW / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com