A control method and device based on a power distribution box supporting bidirectional DC voltage conversion

A voltage conversion, bidirectional DC technology, applied in battery/fuel cell control devices, output power conversion devices, conversion of DC power input to DC power output, etc., can solve the problem of high cost of electronic components, achieve easy maintenance, and reduce data. Risk of loss, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

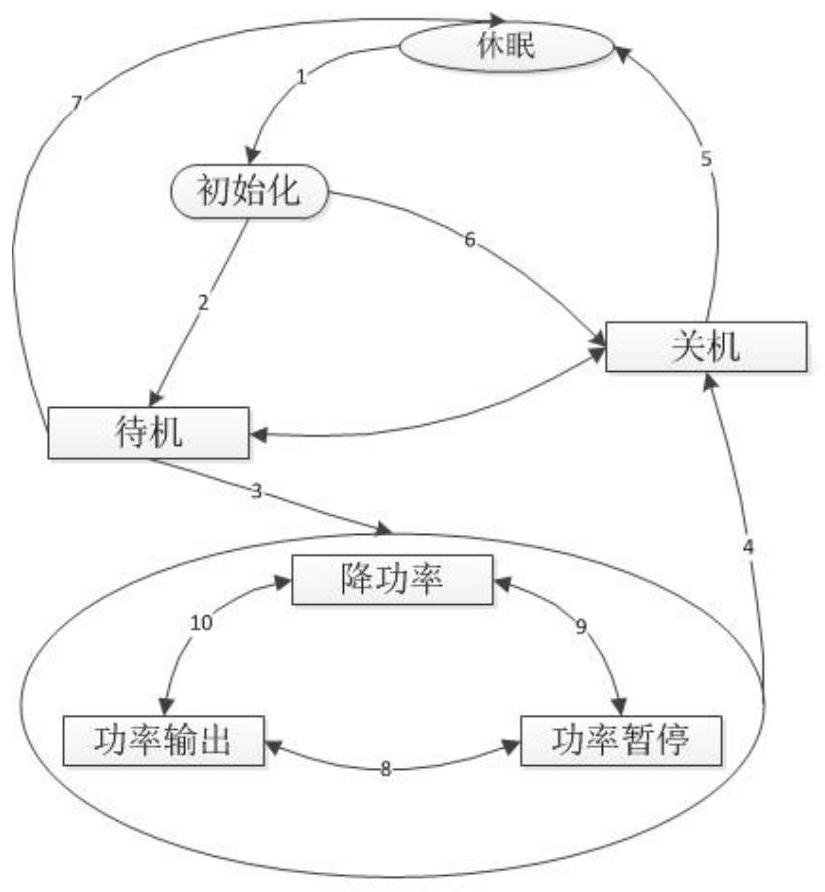

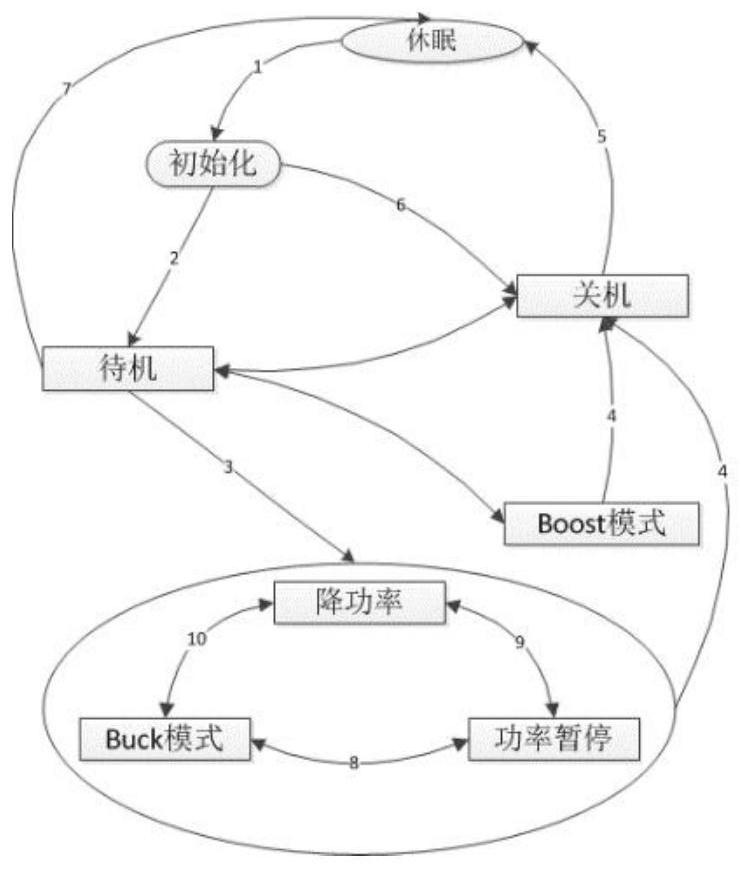

[0061] In this embodiment, the technical problem to be solved by the present invention is that the normal operation of traditional power distribution products and DCDC products is to first engage the high-voltage main circuit and then perform pre-charging. After the pre-charging is completed, the high-voltage circuit is responsible for the normal operation of the equipment, but the pre- The cost of electronic components required for the charging function is relatively expensive. A control method and device based on a power distribution box supporting bidirectional DC voltage conversion is provided. The control method based on a power distribution box supporting bidirectional DC voltage conversion includes:

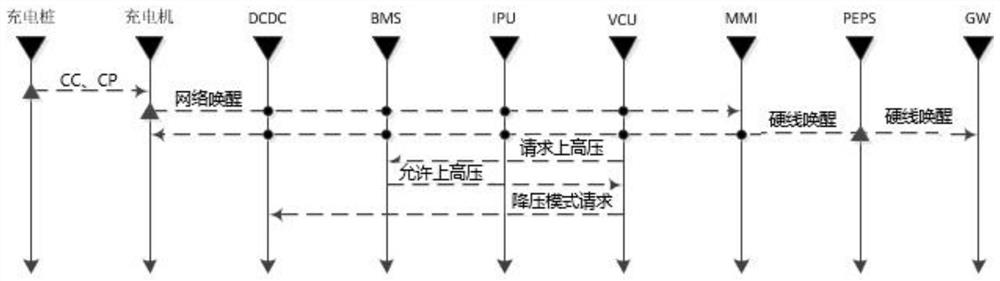

[0062] When the vehicle is dormant, the vehicle network can be woken up by one-key start;

[0063] After the vehicle network wakes up, the vehicle controller judges whether the integrated power unit is insulated, if so, controls the bidirectional DC voltage conversion device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com