Lithium battery energy storage efficient heat management unit

A thermal management and lithium battery technology, applied in vehicle energy storage, secondary batteries, battery temperature control, etc., can solve problems such as increased production costs, waste of energy consumption, and single cooling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

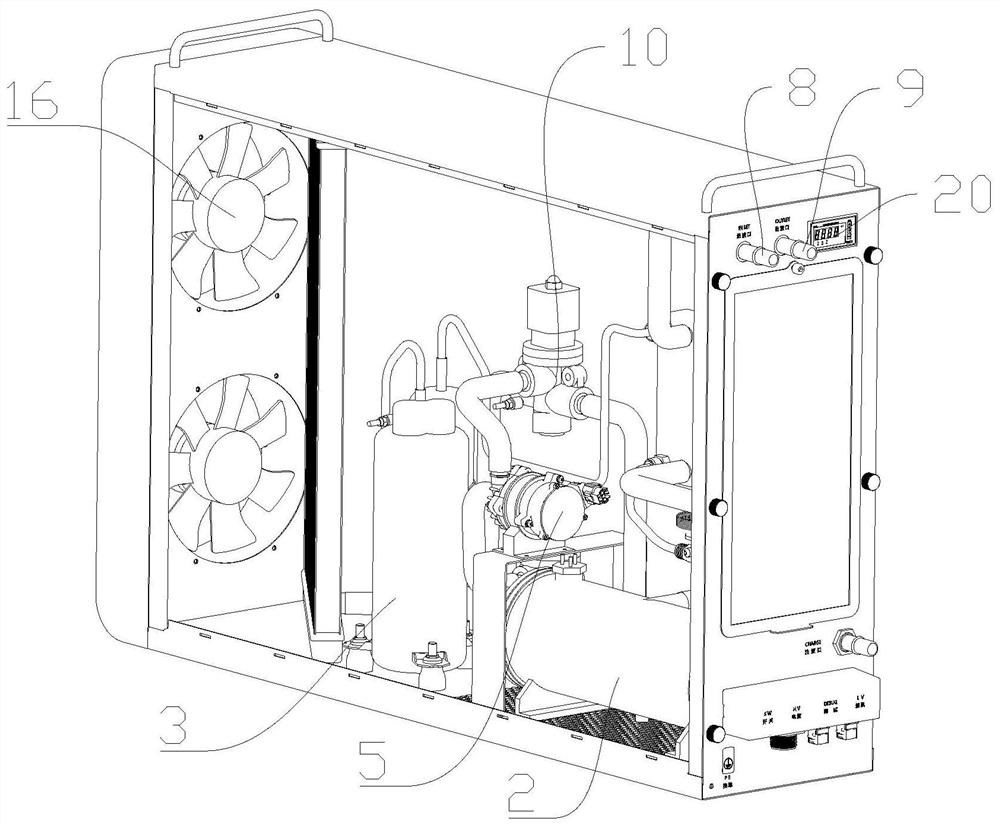

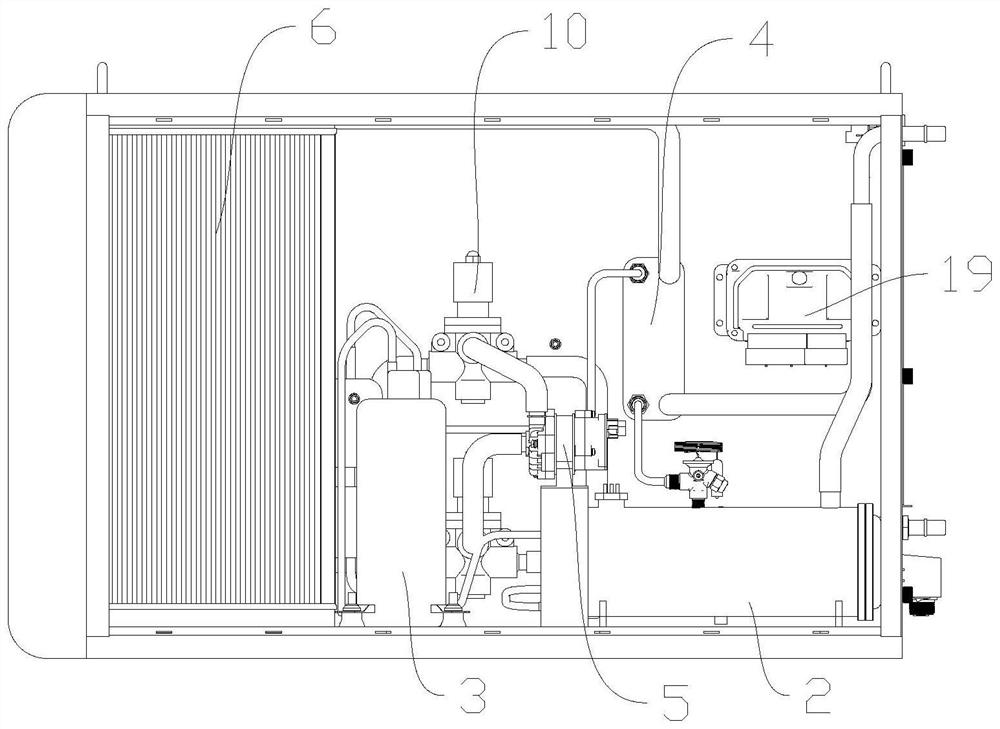

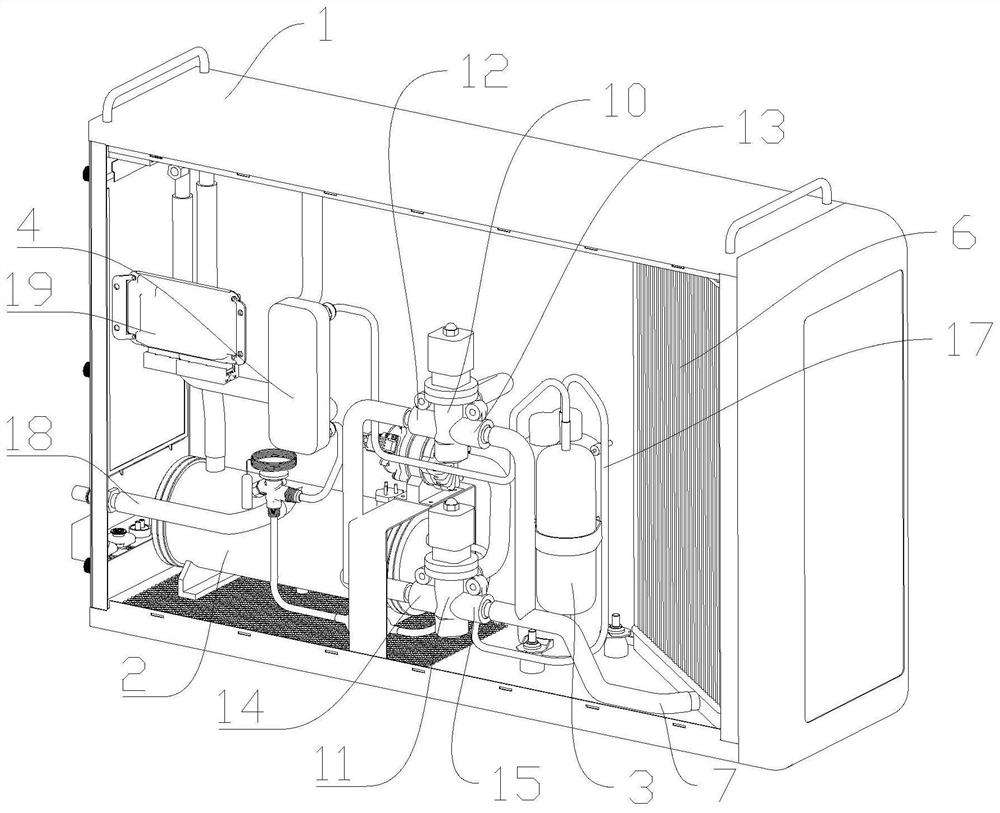

[0020] As in the accompanying drawings Figure 1 to Figure 5 A lithium battery energy storage high-efficiency thermal management unit is shown, including a box body 1, a shell-and-tube condenser 2, a compressor 3, a plate heat exchanger 4, a water pump 5, a low-temperature radiator 6, and an antifreeze pipeline 7. A liquid inlet pipe 8 and a liquid outlet pipe 9 are installed on one side of the body 1, and the shell-and-tube condenser 1 and the liquid inlet pipe 8 are connected through an antifreeze pipe 7, and a three-way two-position solenoid valve A10 and The three-way two-position solenoid valve B11, the first valve port 12 of the three-way two-position solenoid valve A10, and the third valve port 14 of the three-way two-position solenoid valve B11 are all connected to the shell-and-tube condenser 2 through the antifreeze pipeline 7, The second valve port 13 of the three-way two-position solenoid valve A10 and the fourth valve port 15 of the three-way two-position solenoid...

Embodiment 2

[0026] As in the accompanying drawings Figure 6 A lithium battery energy storage high-efficiency thermal management unit shown in the figure has two working modes, cooling mode and heating mode, and the cooling mode can be divided into three levels according to the cooling intensity, divided into The low gear, middle gear and high gear are implemented by turning on different numbers of cooling fans in the low gear and the middle gear, and the high gear is to turn on the compressor for operation. The cooling operation path of these three gears is the same;

[0027] Here, take the high-end operation mode as an example. First, a part of antifreeze liquid is injected through the liquid injection pipe 18, so that the internal water pump 5 can run, and then the compressor starts to work, and the refrigerant is pressurized by the compressor. After the shell-and-tube condenser 2 is cooled, it changes from a gaseous state to a liquid state, and the liquid refrigerant enters the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com