Graphene heating ceramic tile

A technology of graphene and ceramic tiles, which is applied in the field of architectural ceramics, can solve the problems of complex preparation process, instability, and low thermal efficiency, and achieve the effects of simple maintenance and troubleshooting, safety assurance, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further illustrated by the following examples, but these examples are only exemplary, and the present invention is not limited thereto.

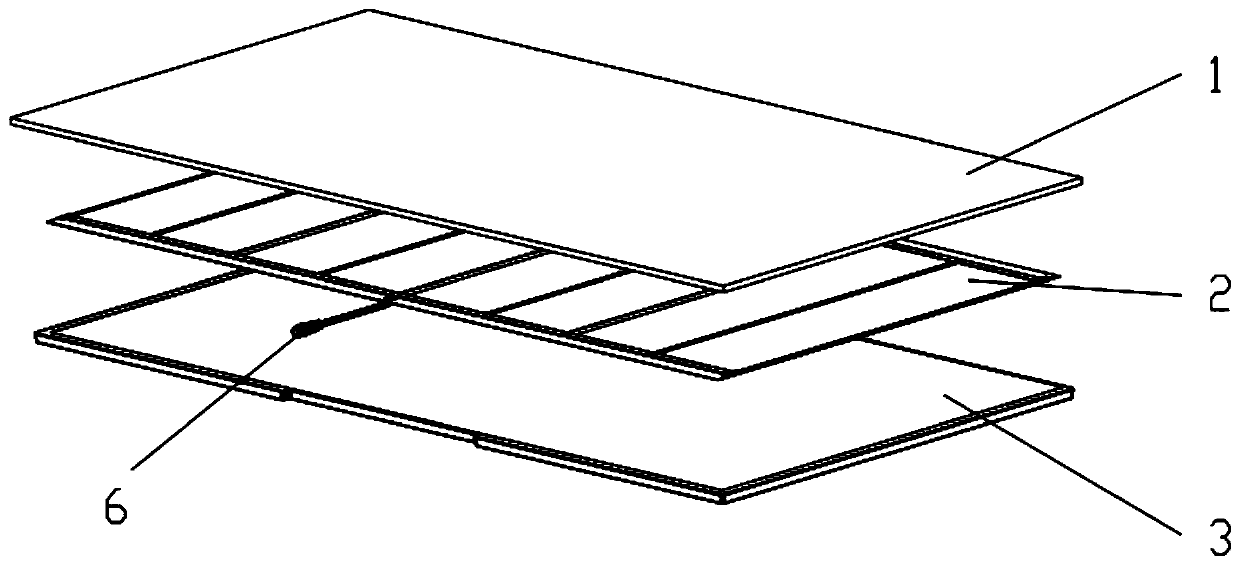

[0034] Such as figure 1 with 4 As shown, a graphene heating ceramic tile of the present invention includes a ceramic tile base 1 and a polyurethane insulation board 2 , and a graphene heating chip 3 is sandwiched between the ceramic tile base 1 and the polyurethane insulation board 2 .

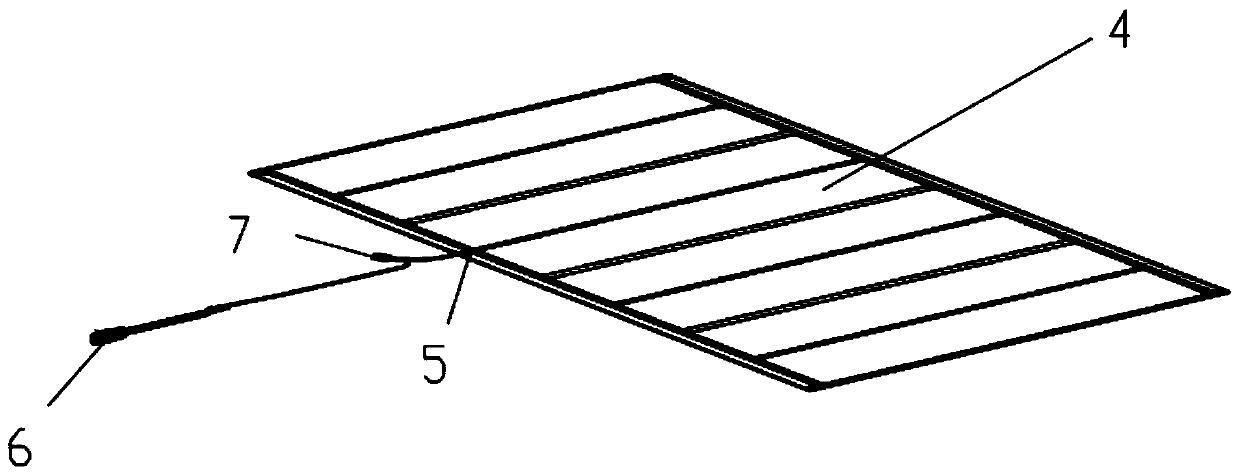

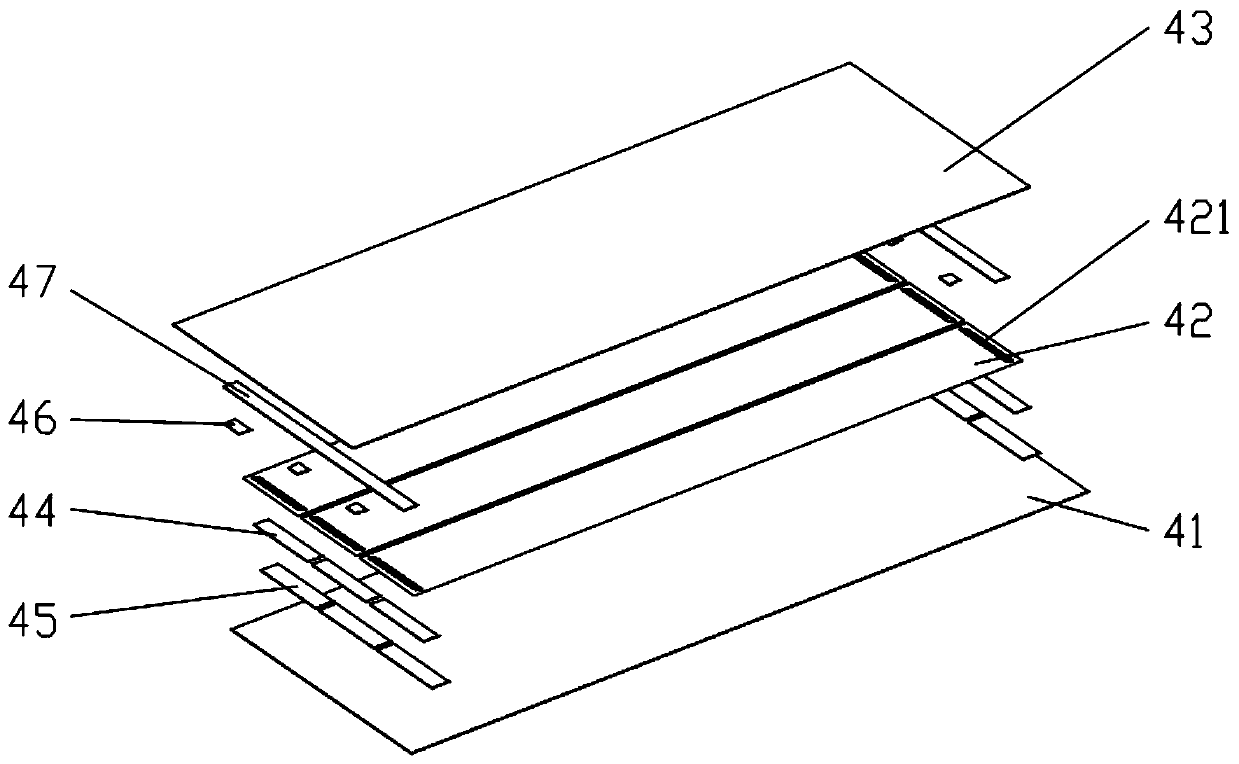

[0035] Such as figure 2 with 3 As shown, the graphene heating chip 3 includes a graphene heating film 4 and a connecting terminal 5, and the graphene heating film 4 includes a PET base film 41 and a plurality of rectangular-shaped graphene heating coatings coated on the PET base film 41. Layer 42, the width of each graphene heating coating 42 is 100-180mm, compared with the whole piece of conductive ink, multiple settings are conducive to the thickness uniformity of graphene heating coating 12, to achieve stable graphene h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com