Anti-sticking spraying device for conveyor belt of glass rod softening furnace

A technology of spraying device and softening furnace, which is applied in the direction of spraying device, liquid spraying device, etc., can solve the problem of non-existence of spraying device, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

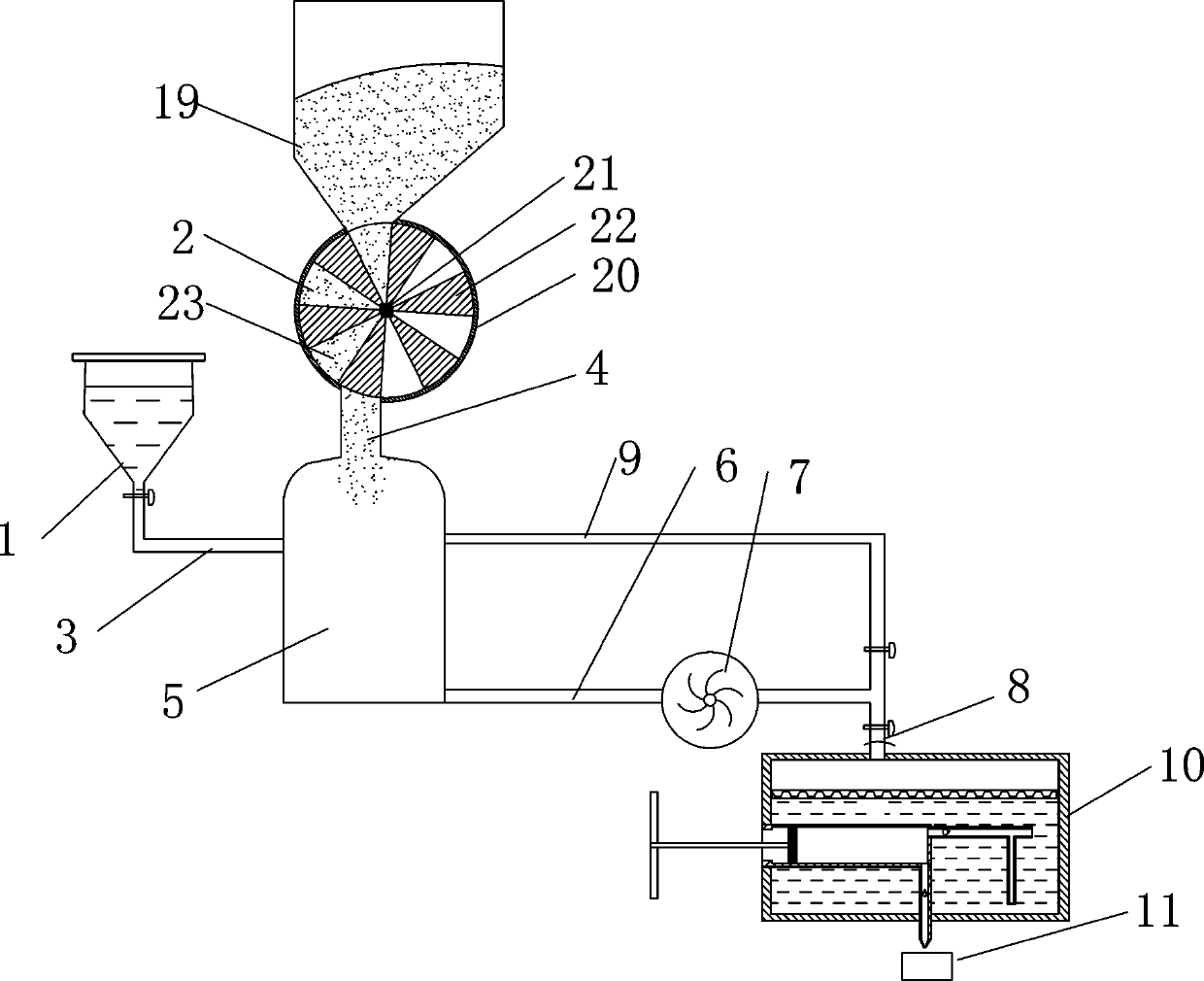

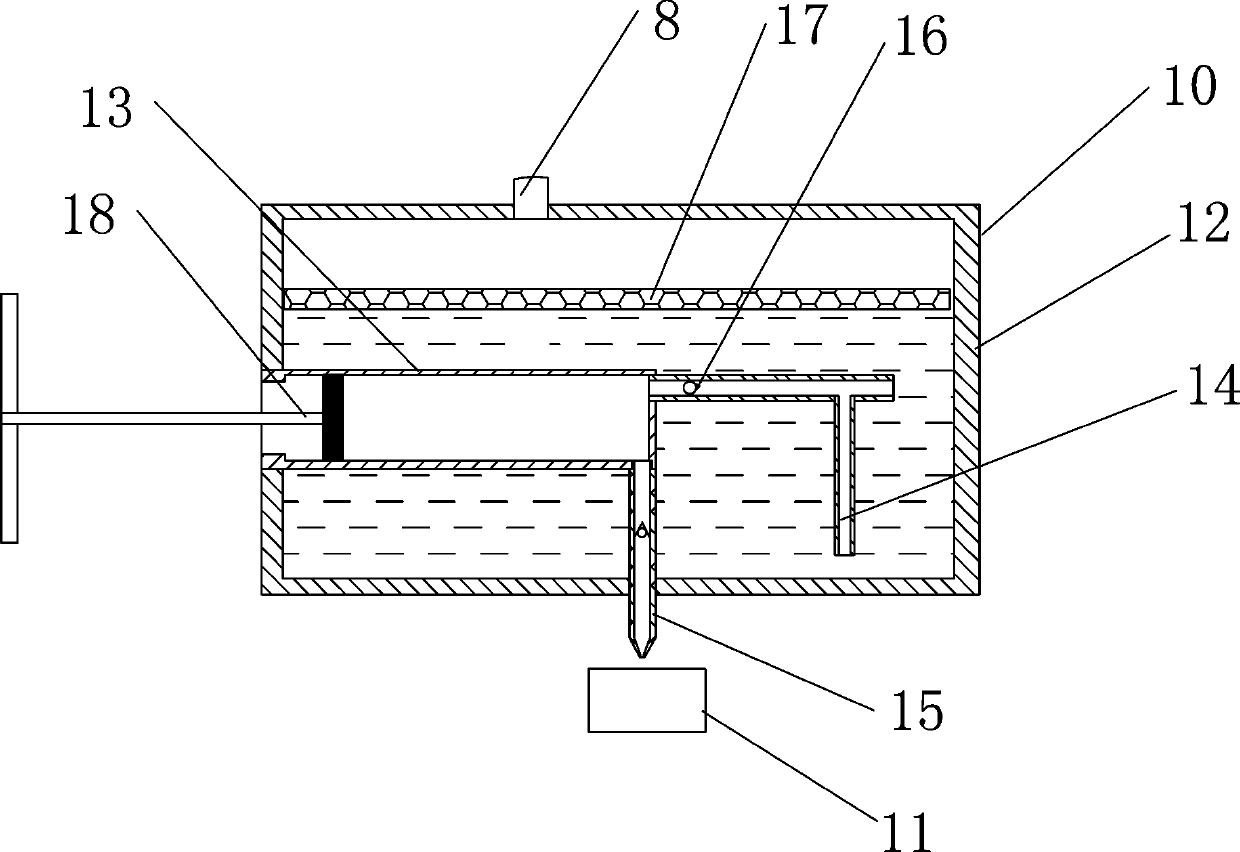

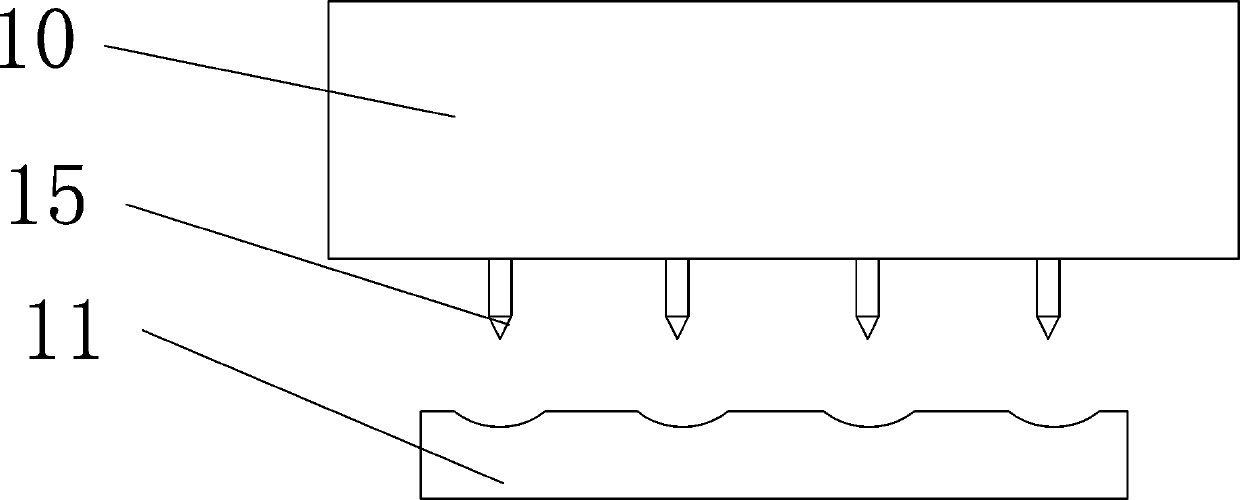

[0018] Such as Figure 1-3 As shown, a glass rod softening furnace conveyor belt anti-stick spraying device is fixedly installed at the entrance of the softening furnace and above the supporting plate of the softening furnace conveyor belt. The spraying device includes a liquid hopper 1 and a powder material distributor 2, and the liquid hopper 1 and the powder material distributor 2 are respectively used for placing monoisopropanolamine and ferric oxide powder. Wherein, the liquid hopper 1 is connected to the mixing box 5 through the liquid inlet pipe 3 with a valve, and the lower end of the powder material distributor 2 is directly arranged above the mixing box 5 through the powder inlet pipe 4 . In addition, a discharge main pipe 6 is provided at the bottom of the mixing box 5, the discharge main pipe 6 is connected to the centrifugal pump 7, the output end of the centrifugal pump 7 is respectively connected to the discharge main pipe 8 and the return pipe 9, and the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com