Copper net laying tool capable of automatic feeding and discharging for intelligent carbon sliding plate

A technology of automatic loading and unloading and carbon skateboard, which is applied in the direction of material gluing, electric vehicles, mechanical equipment, etc., can solve the problems of increasing labor intensity of workers, human influence, time-consuming and labor-intensive, etc., to improve operating efficiency and reduce the influence of human factors , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

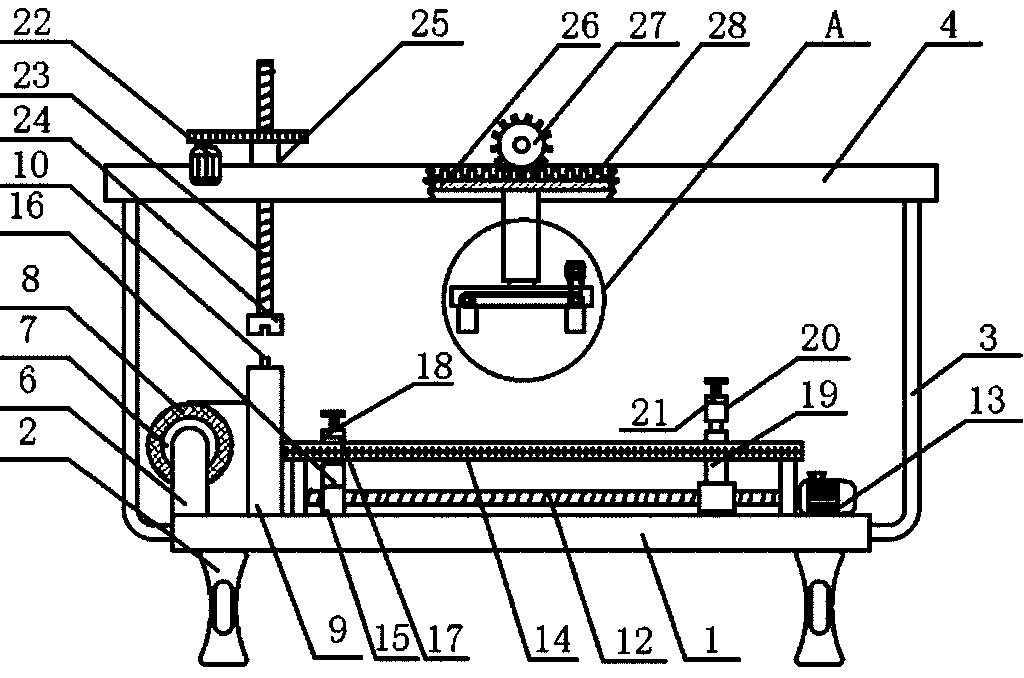

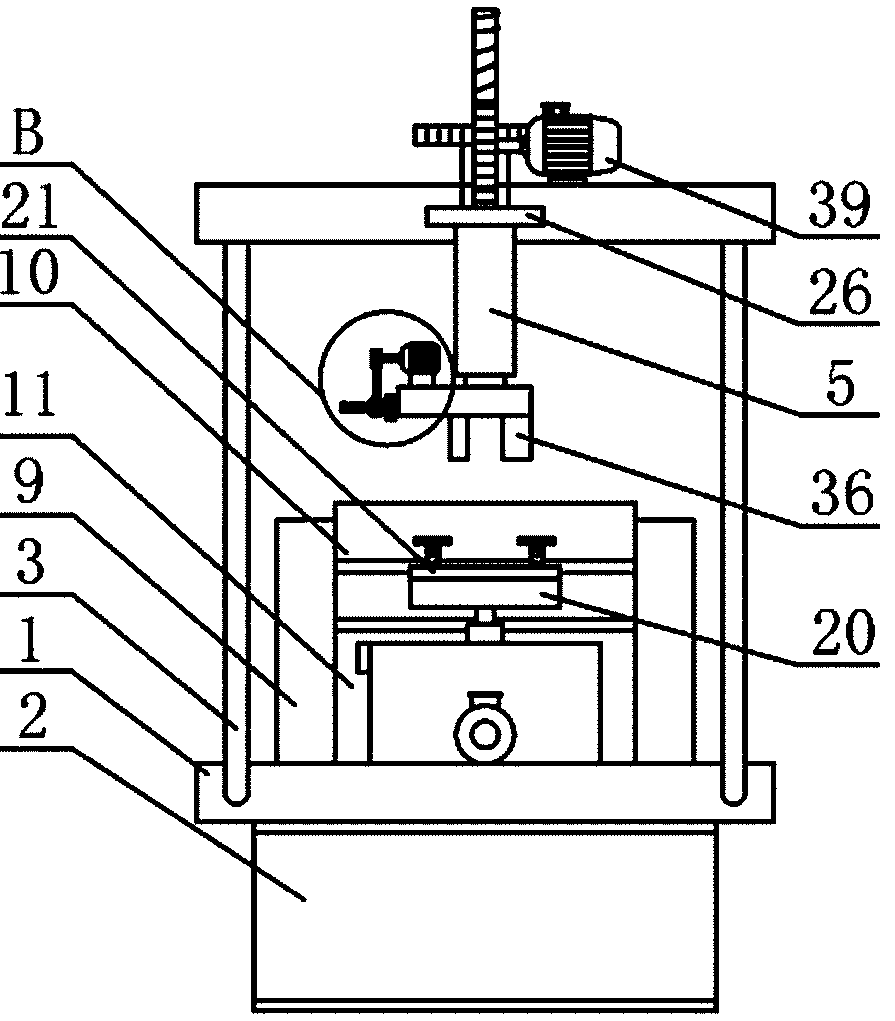

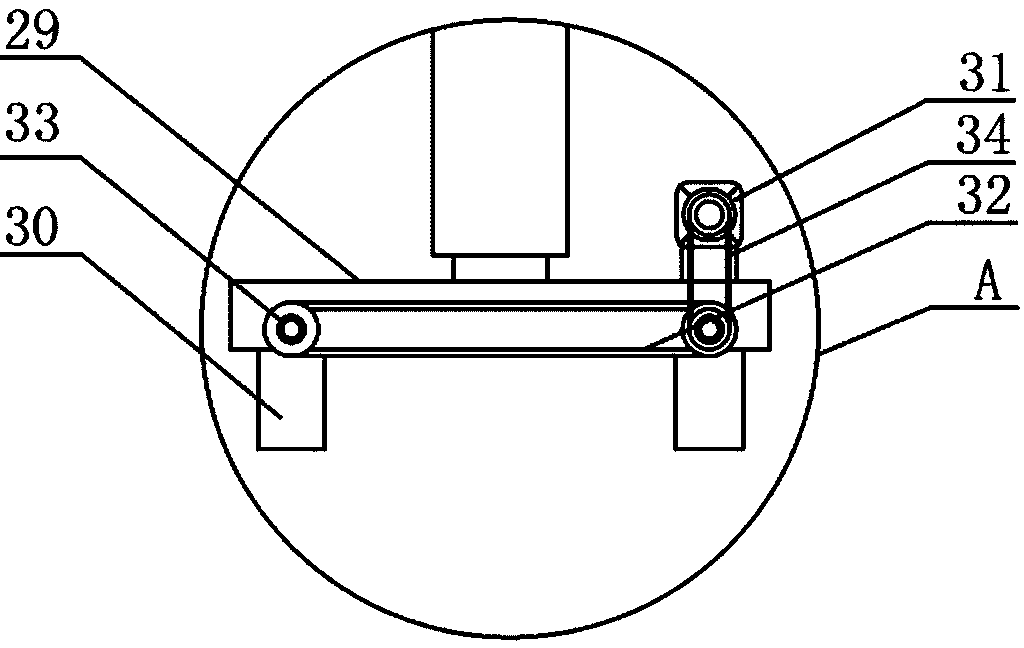

[0027] Example 1: see Figure 1-6 Copper mesh laying equipment for smart carbon skateboards that can automatically load and unload materials, including a base plate 1, both ends of the bottom surface of the base plate 1 are fixedly connected with support seats 2, and both ends of the base plate 1 are fixed with L-shaped Support rod 3, a rectangular top plate 4 is arranged above the top surface of the bottom plate 1, and the four corners of the bottom surface of the top plate 4 are fixedly connected to the top of the corresponding support rod 3, and the middle part of the bottom surface of the top plate 4 slides and is provided with a first electric push rod 5. The movable end of the first electric push rod 5 is fixedly connected with a rectangular connection plate 29, and both ends of the bottom surface of one side of the connection plate 29 are slidingly provided with a rectangular movable splint 30, and the other side of the connection plate 29 is Both ends of the side botto...

Embodiment 2

[0033] Example 2: see Figure 7 , the method of using the copper mesh laying tooling for intelligent carbon skateboards that can automatically load and unload materials includes the following steps:

[0034] Step 1, turn on the power switch, control the moving motor 39 to rotate forward, the moving motor 39 drives the translation gear 27 to rotate, the translation gear 27 drives the rack 28 to move outward, the rack 28 drives the support slide 26 to move outside, and the support slide 26 drives the first The electric push rod 5 moves outwards, and after moving to a suitable position, the mobile motor 39 is controlled to stop rotating;

[0035] Step 2: Control the extension of the first electric push rod 5, the first electric push rod 5 drives the connecting plate 29 to move down, and the connecting plate 29 drives the fixed splint 36 and the movable splint 30 to move down until the other carbon skateboard is located on the fixed splint 36 and the movable splint Between the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com