Winch control system for variable diameter cables and control method thereof

A control system and variable diameter cable technology, applied in the direction of the spring mechanism, hoisting device, etc., can solve the problems of low degree of intelligence, chaotic cable arrangement, cumbersome process, etc., and achieve precise control, reasonable cable arrangement, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

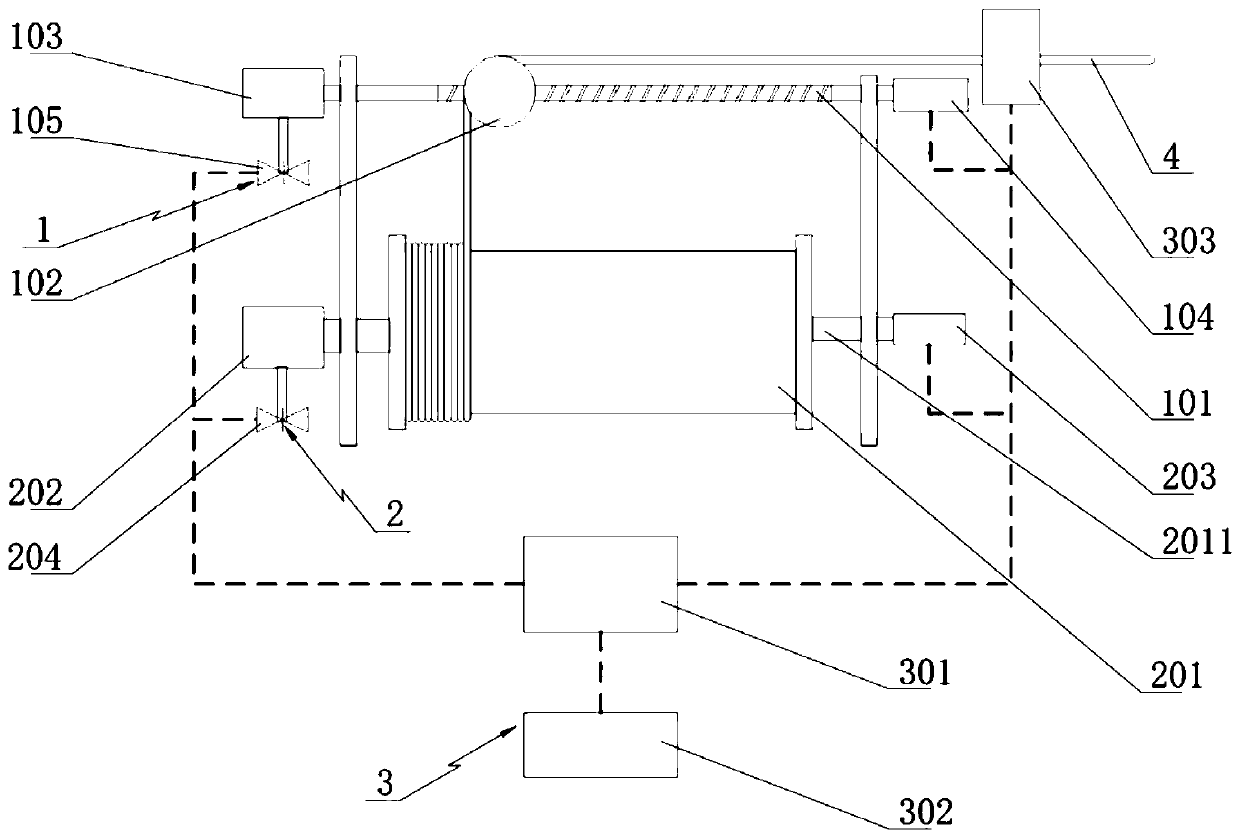

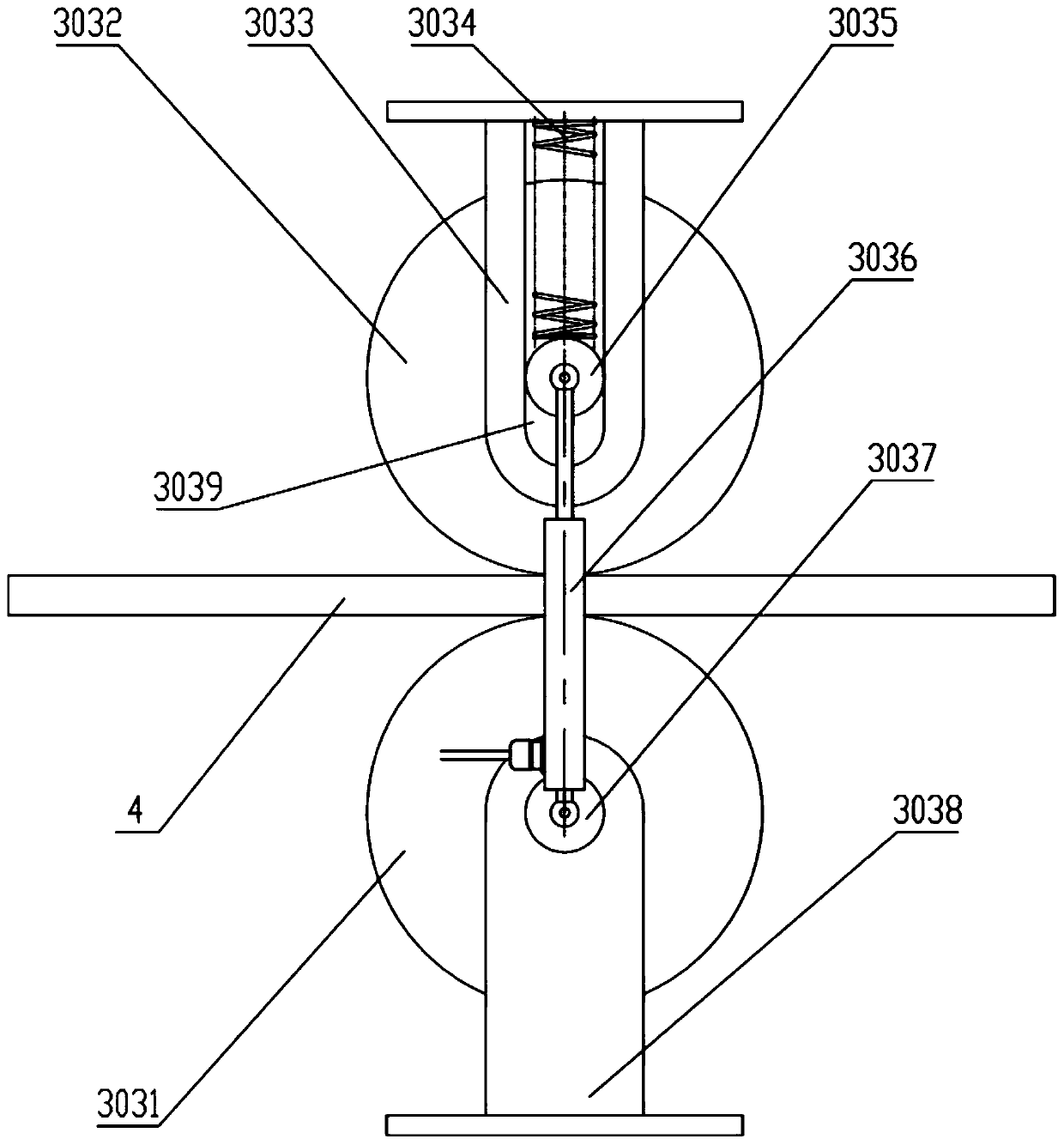

[0096] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

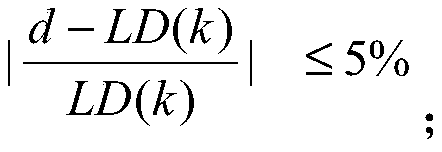

[0097] Such as figure 1 and figure 2 As shown, the present invention includes a lead screw mechanism 1 for controlling the lateral feed of the cable 4 and a reel mechanism 2 for controlling the rotation and winding of the cable 4. The lead screw mechanism 1 and the reel mechanism 2 cooperate to complete the unwinding and winding of the cable 4 The cable take-up movement also includes a control mechanism 3, which collects the rotation angle information and cable diameter information from the screw mechanism 1 and the reel mechanism 2, and obtains and stores various parameters of the cable 4 through calculation, and at the same time sends the information to the screw mechanism 1 and the reel mechanism 2 feed back the rotation speed adjustment command.

[0098] Lead screw mechanism 1 comprises cable-discharging leading screw 101, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com