Molten steel smelting method of mammoth converter

A molten steel smelting and large-scale converter technology, applied in the manufacture of converters, etc., can solve the problems of inability to remove harmful elements in molten iron, low production efficiency, and affecting the quality of molten steel, and achieve the effects of shortening smelting time, increasing production efficiency, and improving molten steel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

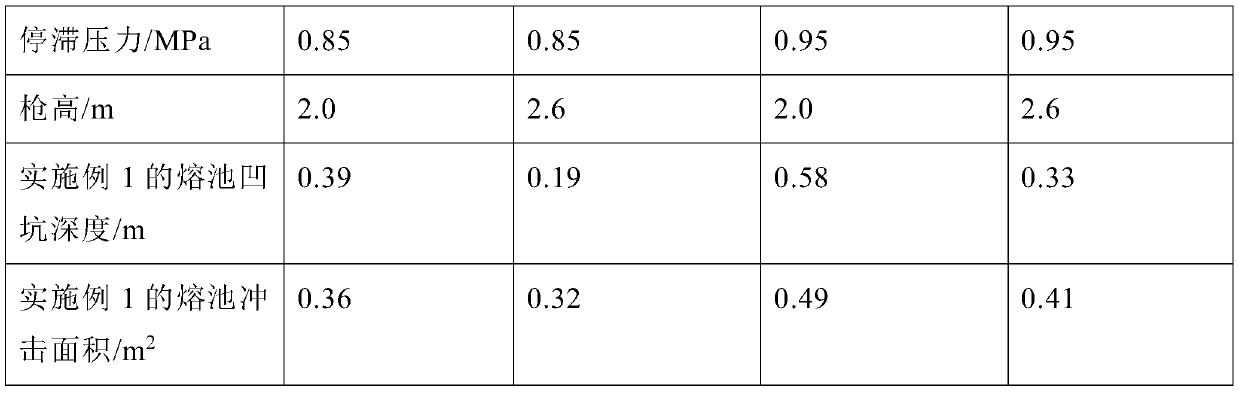

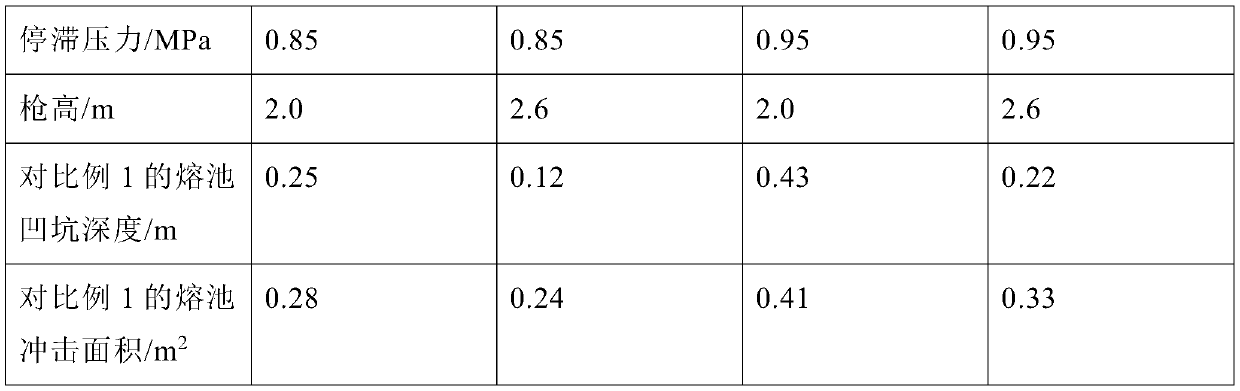

[0039] The oxygen lance nozzle provided in the molten steel smelting method using a large converter, that is, the throat diameter of the oxygen lance nozzle is 43.5mm, the outlet diameter of the oxygen lance nozzle is 57mm, the included angle of the oxygen lance nozzle is 13-14°, and the oxygen supply intensity is 4.0m 3 / (t min), and set the oxygen supply flow rate to 42000Nm during the blowing process 3 / h. Observe the impact depth and impact area formed by the oxygen flow when the oxygen lance nozzle is used for high-intensity oxygen supply. The specific data are shown in Table 1.

[0040] Table 1:

[0041]

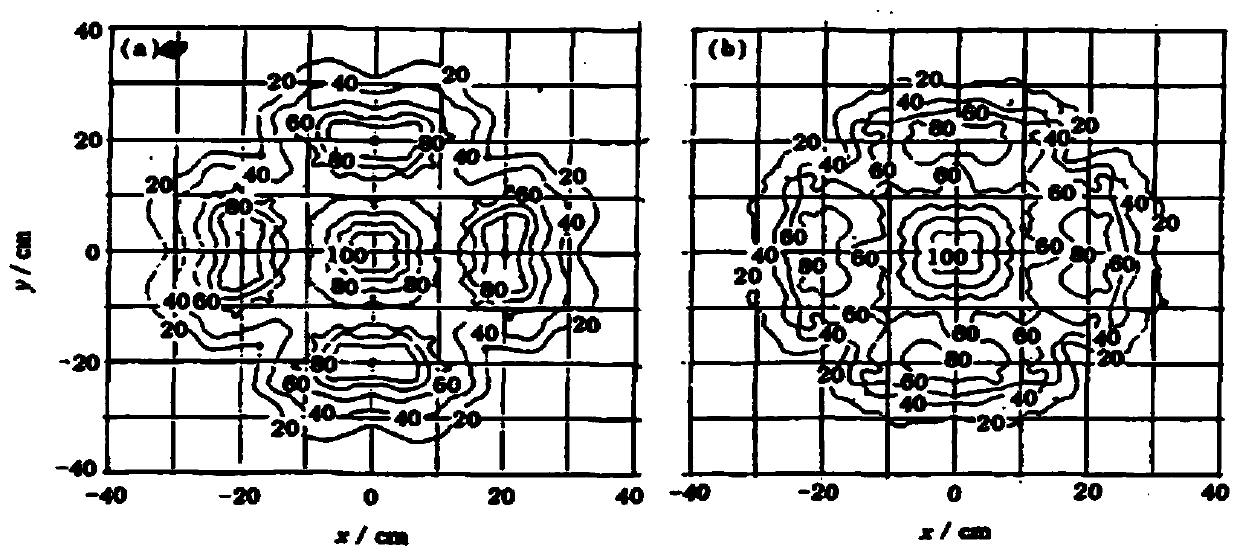

[0042] in, figure 1 Impact area and impact depth plots for oxygen flow.

Embodiment 2

[0052] The oxygen supply time of Example 1 was compared with that of Comparative Example 1, and the specific data are shown in Table 4.

[0053] Table 4:

[0054] serial number Number of test furnaces / furnace Working pressure / MPa Average oxygen supply flow / Nm 3 / h

[0055] As can be seen from Table 4, when adopting the molten steel smelting method of large-scale converter in embodiment 1 to carry out oxygen blowing, compared with adopting the existing oxygen lance oxygen blowing in comparative example 1, shortened oxygen supply time and reached 5.3min, and then shortened smelting cycle, which improves the production efficiency of the converter. At the same time, adopting the oxygen lance operation method for large-scale converter smelting in 1 can reduce oxygen consumption, thereby reducing production costs.

Embodiment 3

[0057] The final slag components were compared between Example 1 and Comparative Example 1, and the specific data are shown in Table 5.

[0058] table 5:

[0059] serial number FeO% TFe% P 2 o 5 %

[0060] As can be seen from Table 5, when adopting the molten steel smelting method of the large-scale converter in Example 1 to smelt, compared with adopting the existing oxygen lance in Comparative Example 1 to smelt, the FeO and TFe contents in the final slag all decrease to some extent, indicating that The utilization rate of Fe has increased, and the content of phosphorus pentoxide in the final slag has increased, indicating that the dephosphorization rate has increased, and the alkalinity has decreased, indicating that the consumption of slagging materials has been reduced. It can be seen that when the molten steel smelting method of the large-scale converter in Example 1 is used for smelting, the quality of molten steel can be effectively improved and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com