Capacity pressure measurement method, system and device suitable for production system and storage medium

A technology of production system and capacity, which is applied in the direction of data error detection, error detection/correction, and response error generation, which can solve the problems of large differences in production environments, difficult evaluation of production capacity, and test capacity results. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Various aspects of the present invention will be described in detail below with reference to the drawings and specific embodiments. Wherein, well-known modules, units and their mutual connections, links, communications or operations are not shown or described in detail. Also, the described features, architectures, or functions may be combined in any manner in one or more implementations. It should be understood by those skilled in the art that the various implementations described below are only for illustration, rather than limiting the protection scope of the present invention. It can also be easily understood that the modules or units or processing methods in the embodiments described herein and shown in the accompanying drawings can be combined and designed in various configurations.

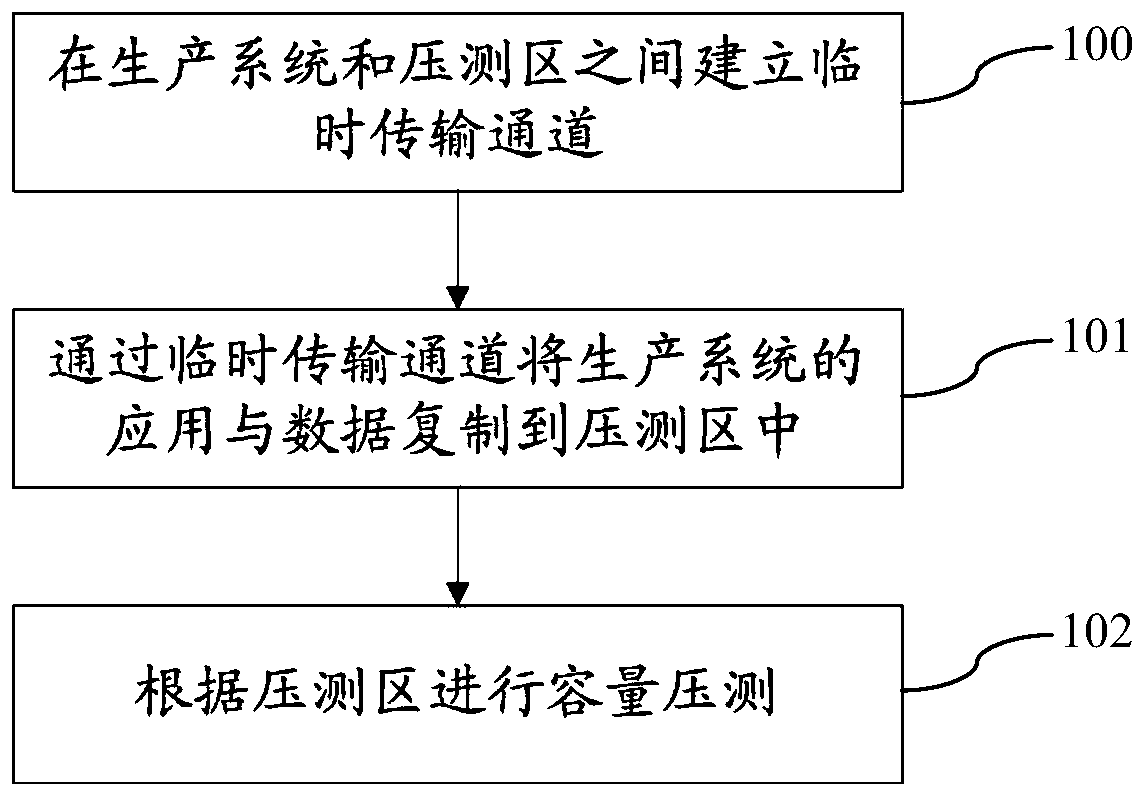

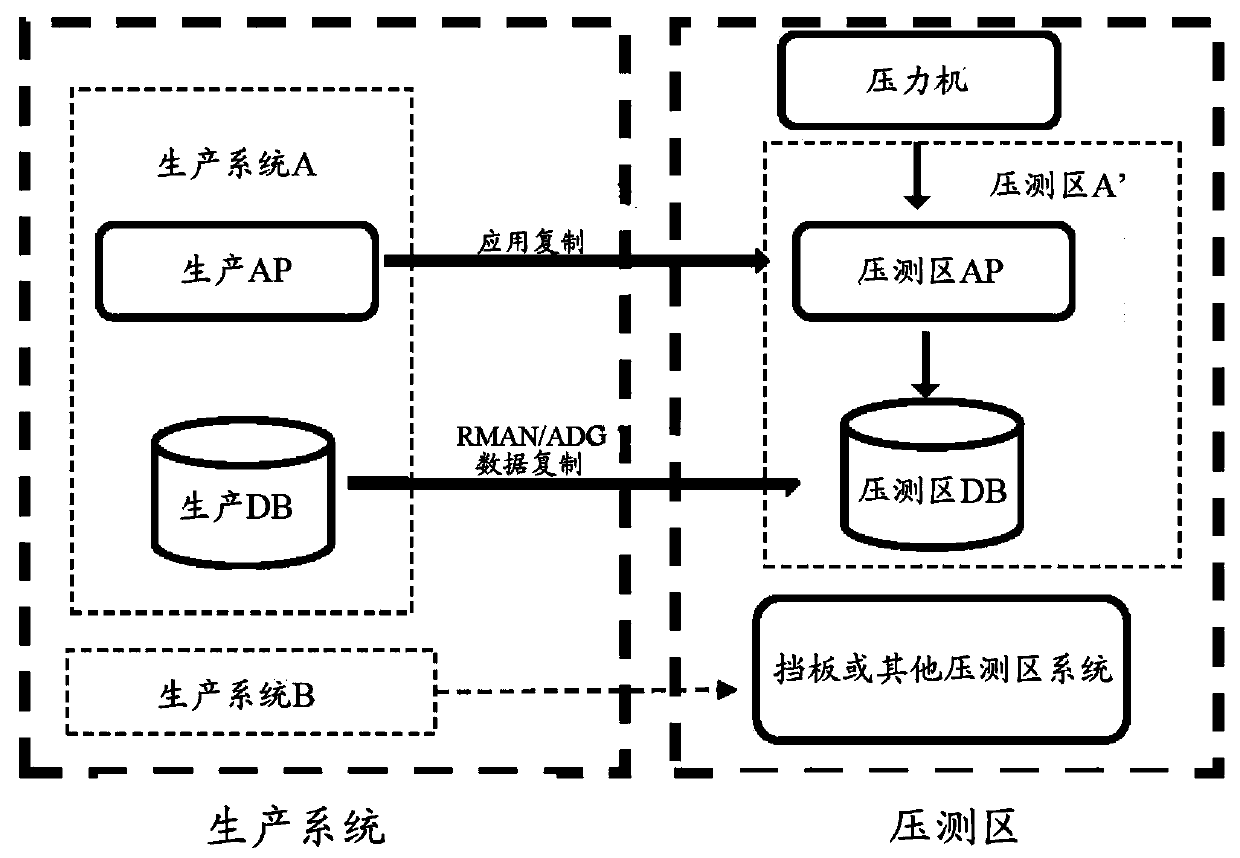

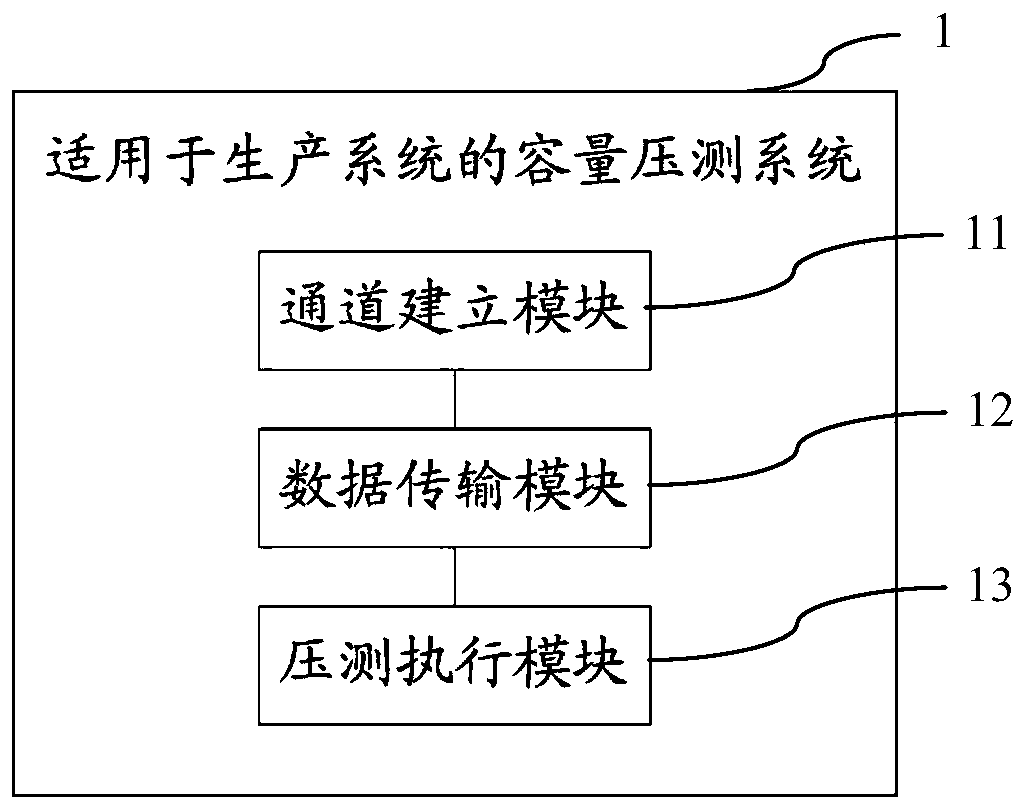

[0024] figure 1 is a schematic flowchart of a capacity pressure measurement method suitable for a production system according to an embodiment of the present invention. In the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com