Novel super-barrier power device and manufacturing method thereof

A technology of a power device and a manufacturing method, which is applied to a new type of super-barrier power device and its manufacturing field, can solve the problems of small reverse recovery peak current, short reverse recovery time, and high reverse blocking voltage, and achieve reverse recovery. Small peak current, short reverse recovery time, and lower on-voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

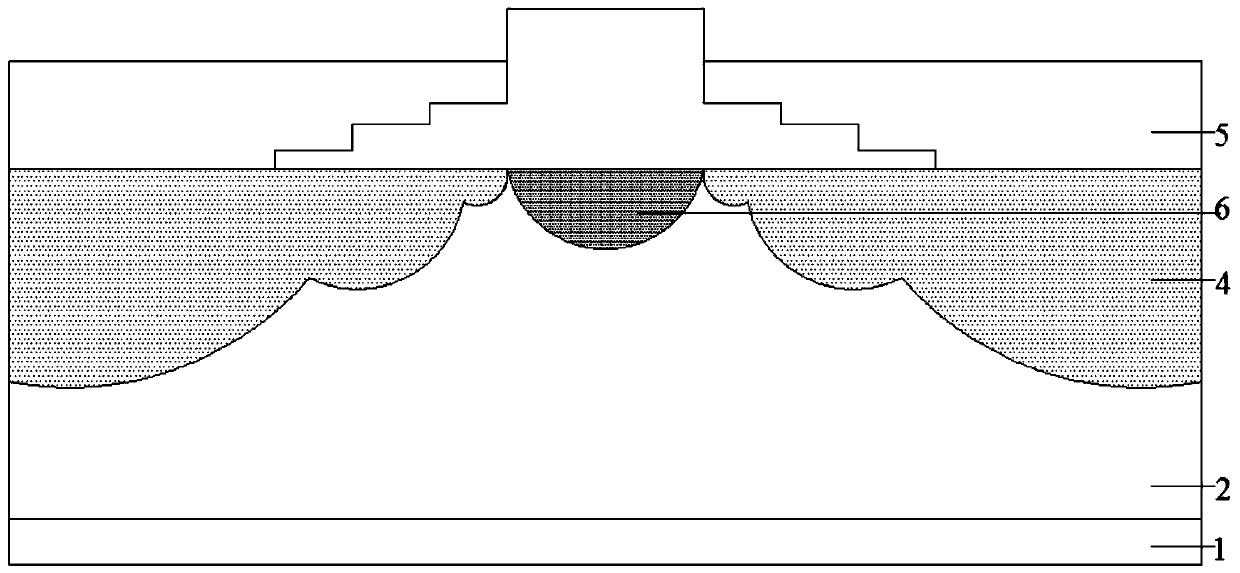

[0066] see Figure 1-7 , this implementation 1 provides a method for manufacturing a novel super-barrier power device, which specifically includes the following steps:

[0067] (1). Provide an N-type substrate including an N-type epitaxial layer; the resistivity of the N-type substrate is <0.005Ω / cm, the thickness of the N-type epitaxial layer is 9 μm, and the resistivity is 2.5Ω / cm, the figure is omitted;

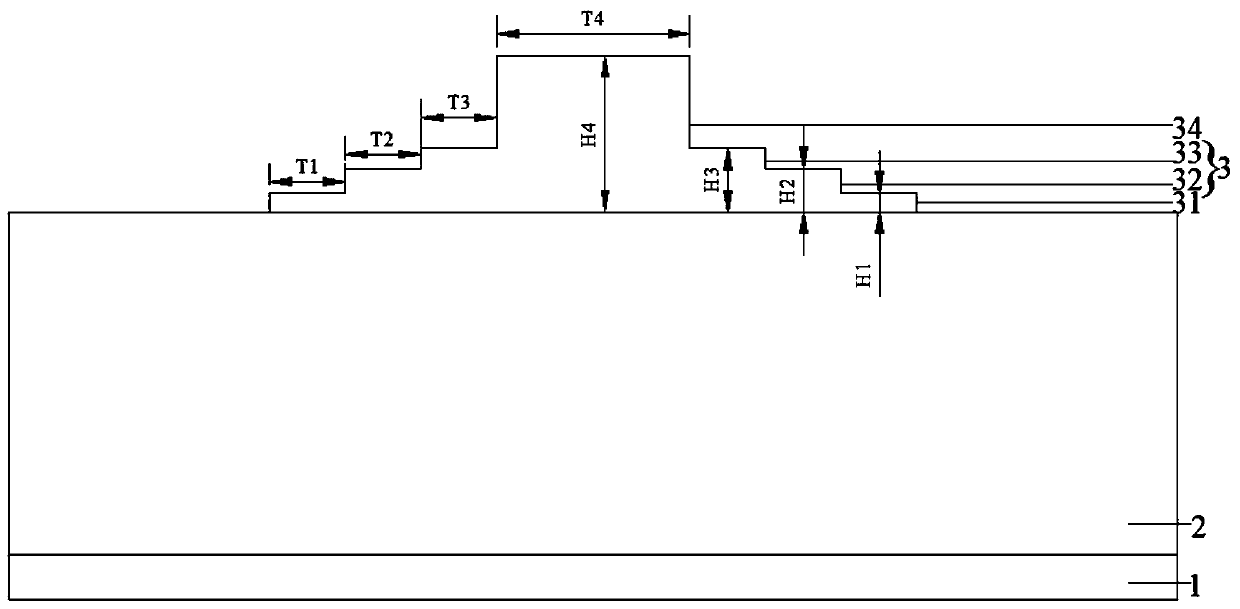

[0068] (2). On the N-type epitaxial layer 2, grow a silicon oxide layer with a thickness of 7500 angstroms at 1050 ° C, and form a ladder structure after three photolithography and etching, that is, the first oxide layer 31, the second oxide layer 32, the third oxide layer Oxide layer 33, specifically as figure 1 As shown, among them, T1>2T2=2T3=2T4, H4>2H3, H3>H2>H1, T1 is 2μm, see details figure 1 .

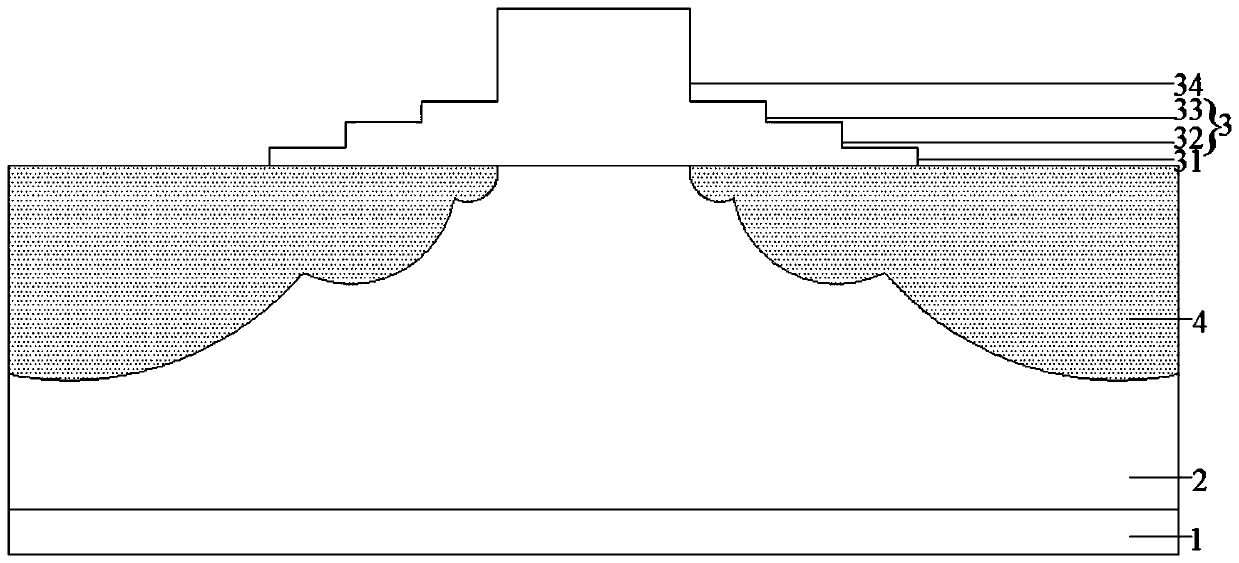

[0069] (3). Perform P-type ion implantation on the surface of N-type epitaxial layer 2, implantation energy 110KeV, implantation dose 3E13; the implantation energy for P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com