Safety valve structure for lithium battery

A safety valve, lithium battery technology, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of battery failure, complex structure, battery dust, etc., to achieve high installation qualification rate, simple overall structure, and durable. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

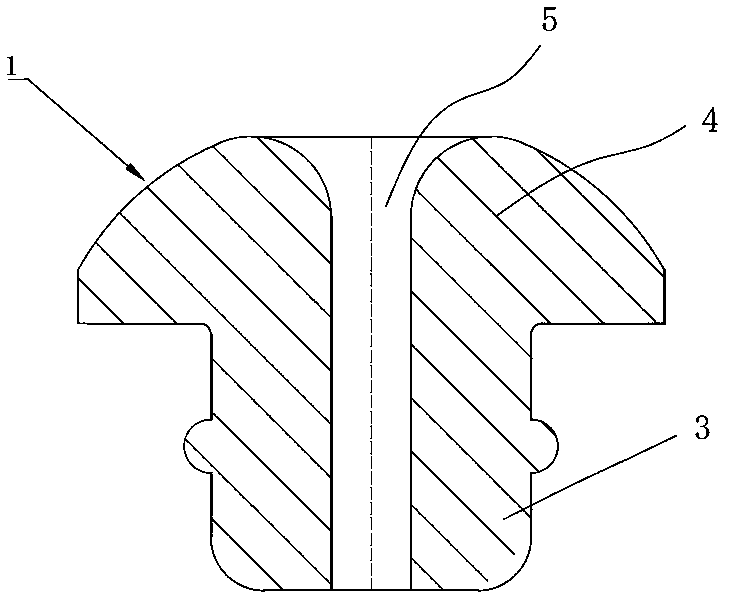

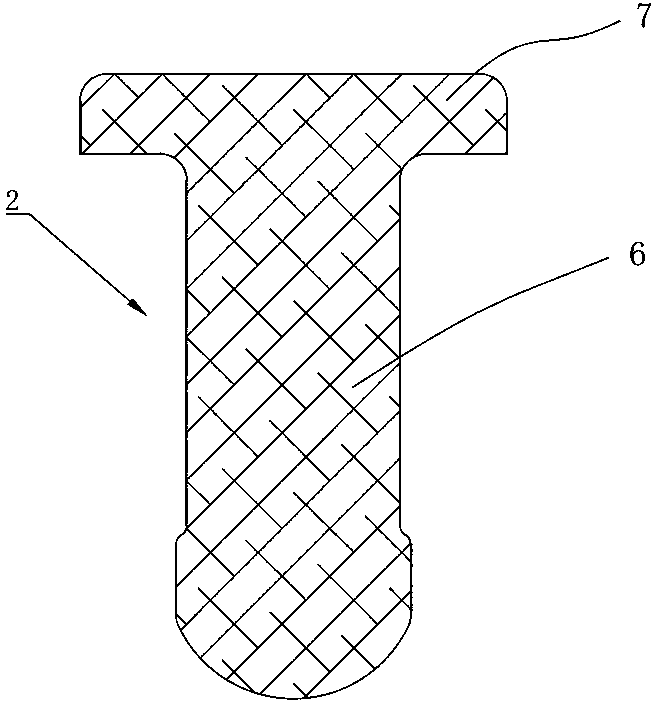

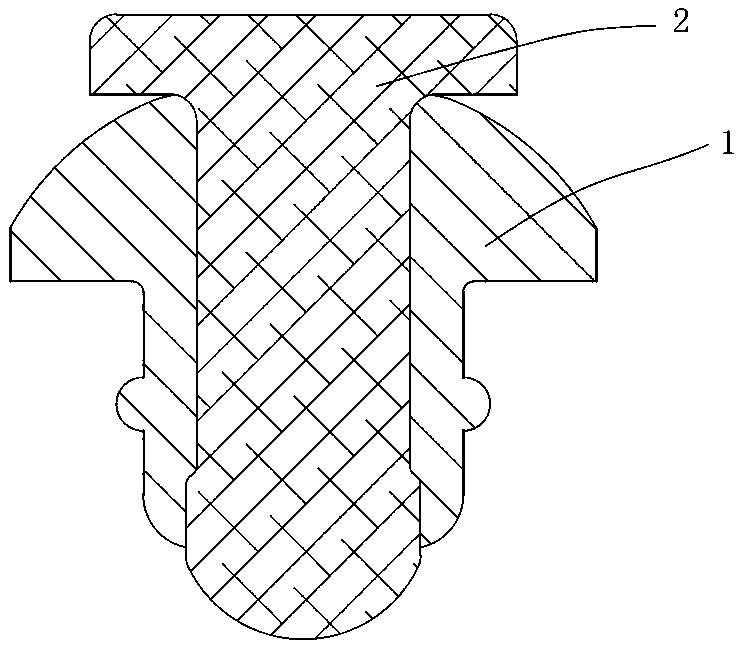

[0026] Embodiment one: see Figure 1 to Figure 4 As shown, a safety valve structure for a lithium battery is composed of a rubber plug 1 and a pin 2, the rubber plug 1 is made of EPDM rubber, and the pin is a metal pin; as figure 1 and figure 2 As shown, the rubber plug 1 is composed of a plug body 3 matching with the battery blast hole and a head 4 with a diameter larger than the plug body. The center of the rubber plug 1 is provided with a through hole 5 along the direction of the symmetry axis of the plug; the pin 2 consists of a pin The main body 6 and the limit head 7 at the upper end are formed. The diameter of the pin body 6 is larger than the inner diameter of the through hole 5. The pin body 6 is clamped in the through hole 5 and presses the wall of the through hole, so that the periphery of the plug body and the battery are blasted. The hole forms an interference fit; the limit head 7 at the upper end of the pin is limited by the head 4 of the rubber plug and is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com