Automatic branching equipment for automobile wire harness

A technology of wire distribution equipment and automobile wiring harness, which is applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of high labor intensity, low production efficiency, high labor cost, etc., and achieve low error rate, accurate positioning, The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

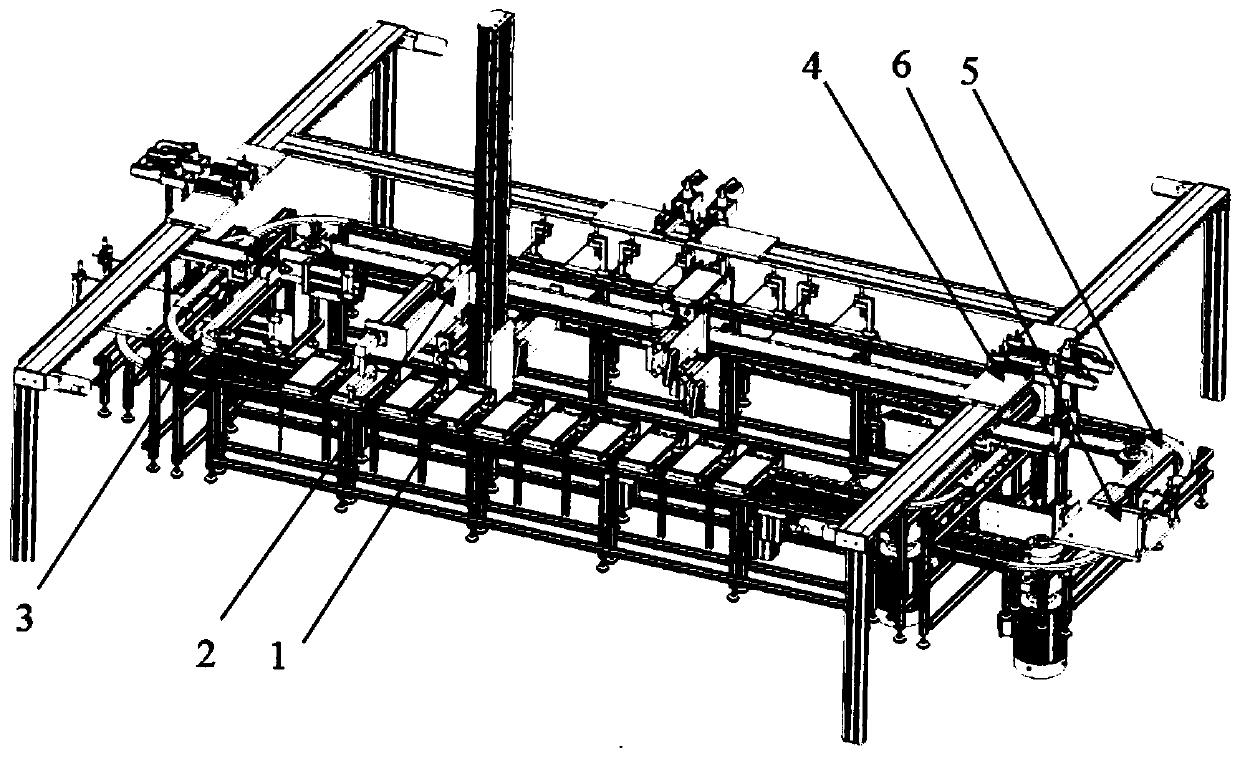

[0027] refer to figure 1 , the specific embodiments of the present invention include:

[0028] A number of wire harness trays 1 are installed on the upper accumulation type conveying line 3, and are connected with the upper accumulation type conveying line 3, and are used to place wire harness materials of different specifications;

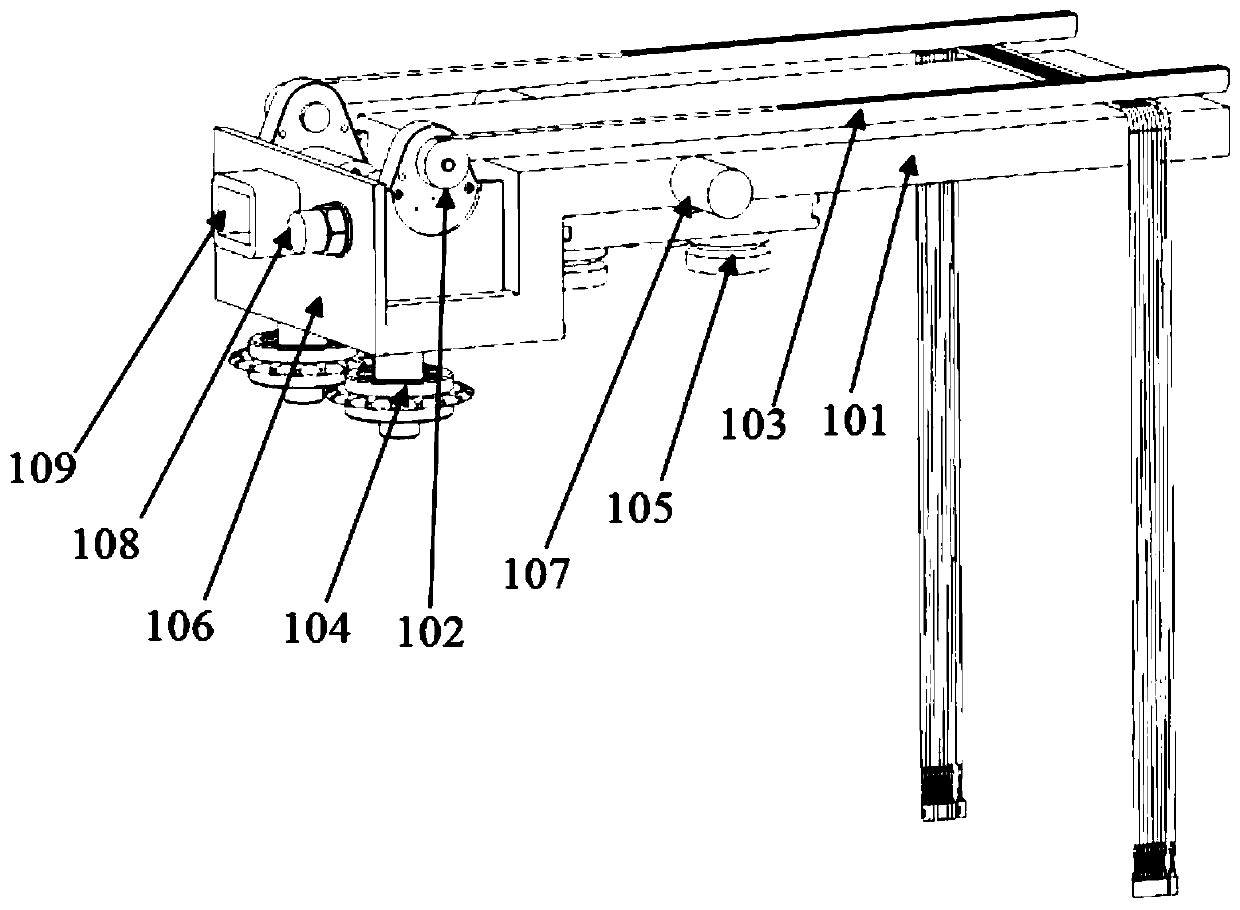

[0029] Rolling mechanism 2, which is installed in the 3 circles of the upper accumulation conveyor line and fixed to the ground, is used to roll the disorderly multi-strand wire harnesses on the wire harness tray into one layer to prepare for the wire separation process;

[0030] Up-and-down conveying line 3, the frame made of profiles is fixed on the ground, and the conveying line installed on the frame is used to transport the line-speed pallet to the designated position of the next process;

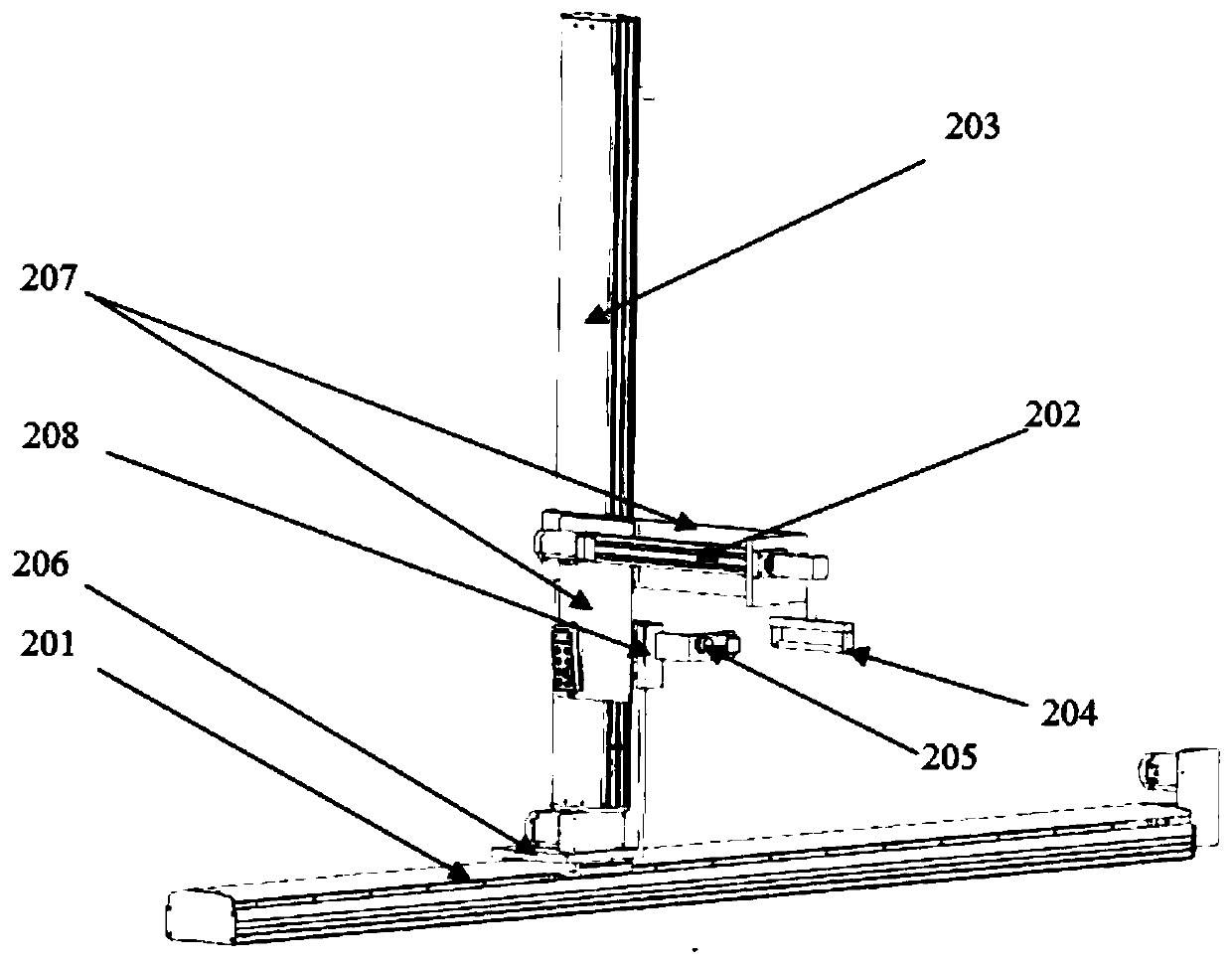

[0031] A number of branching mechanisms 4 are installed on the ground above the upper accumulation type conveying line 3, and are used to separate and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com