Fluidized bed reactor

A technology of reaction device and fluidized bed, which is applied in the field of fluidized bed reaction device, can solve the problems of unstable generation of trichlorosilane, insufficient supply of hydrogen chloride gas, insufficient cooling, etc., and achieve the effect of stable and accurate temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] The method for producing trichlorosilane according to one embodiment of the present invention is carried out using the fluidized bed reactor according to one embodiment of the present invention. Specifically, it is as follows.

[0099] (Apparatus and method)

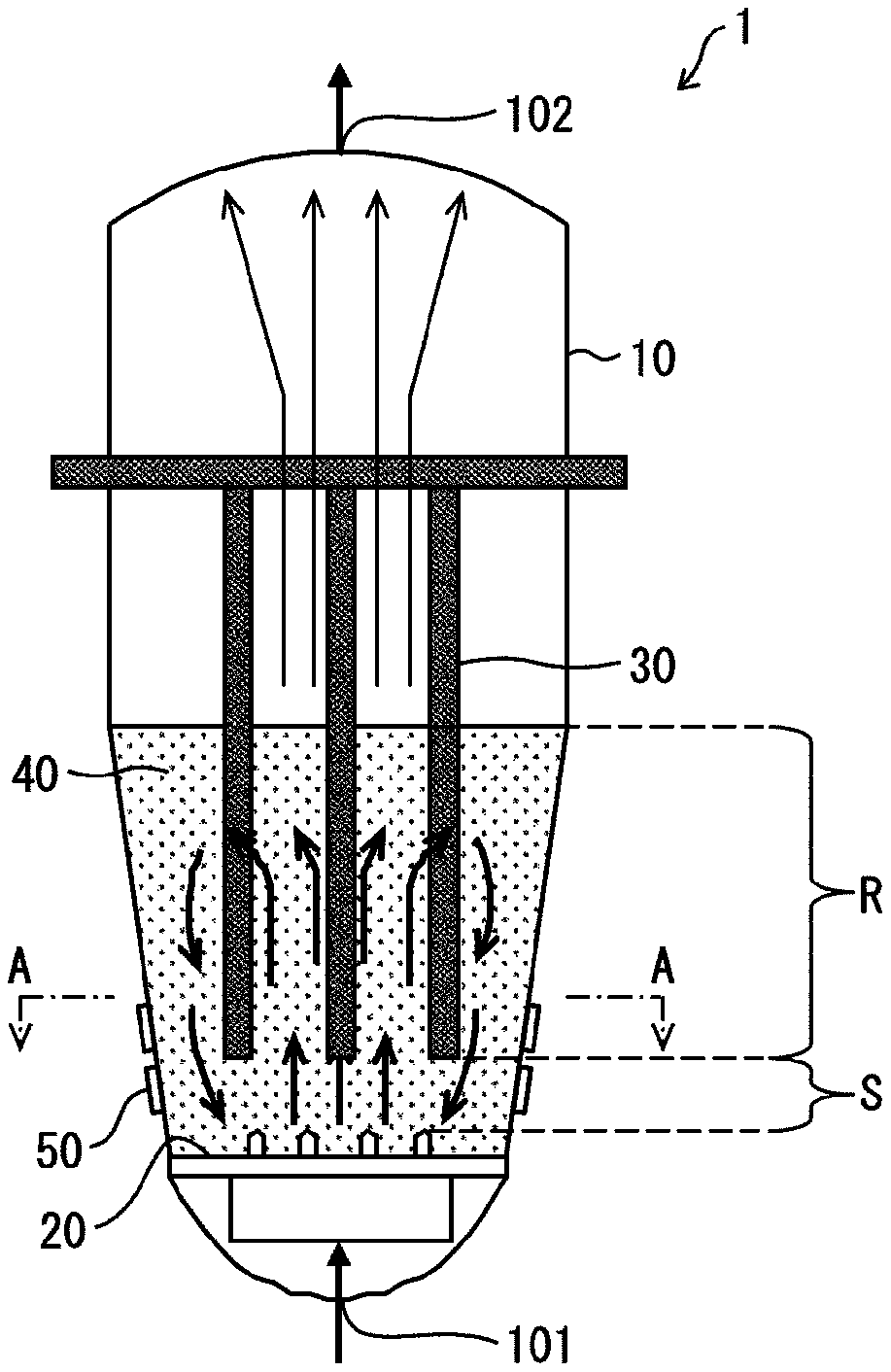

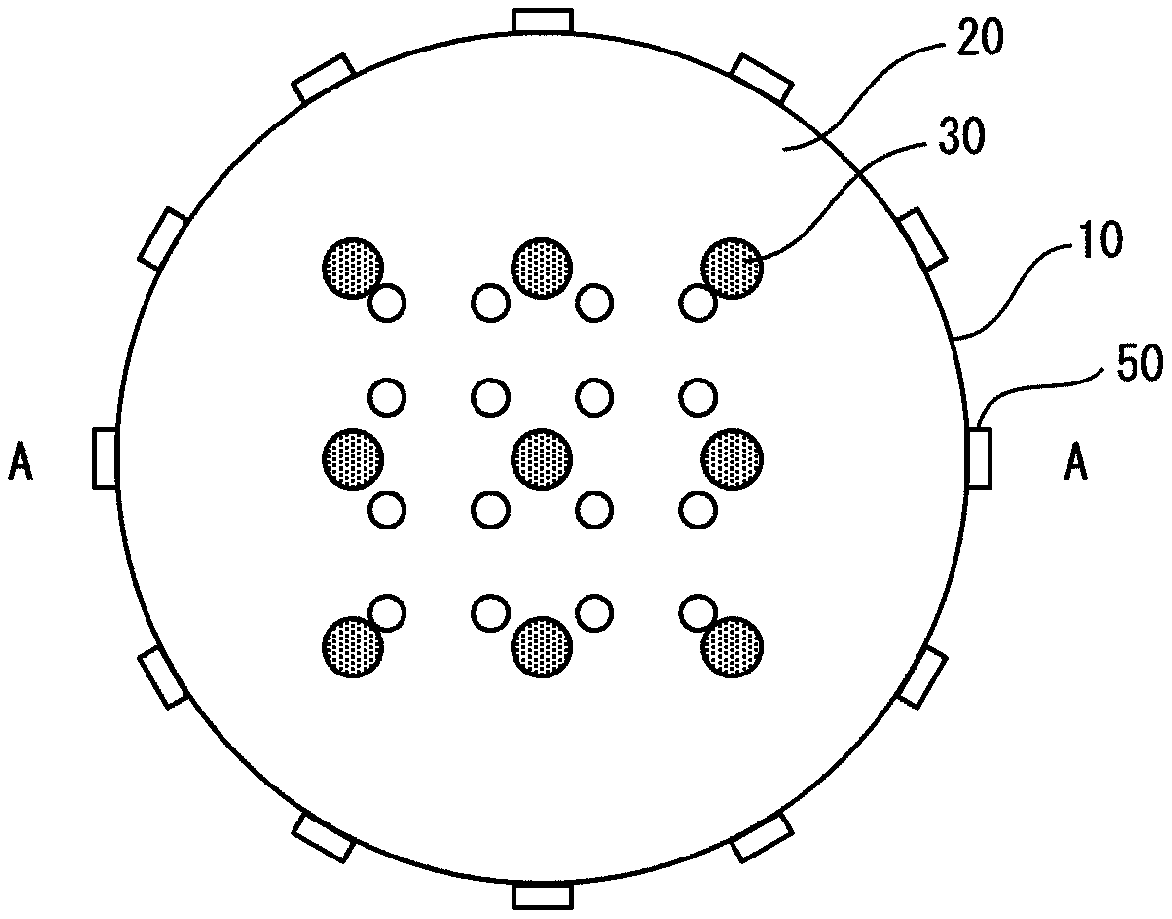

[0100] In the manufacture of trichlorosilane, used with figure 1 as well as figure 2 The fluidized bed reactor shown is the same fluidized bed reactor. For the sake of convenience, the temperature measuring section provided in the vertically lower row among the two rows of temperature measuring sections is used as a lower surface thermometer (hereinafter also simply referred to as a thermometer).

[0101] In addition, the thermometers are evenly arranged in the horizontal direction at intervals of 3 to 4 thermometers / m in the circumferential direction per row.

[0102] In the above-mentioned fluidized bed reactor, metal silicon powder and hydrogen chloride gas are supplied to produce trichlorosilane. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com