A heat exchanger and an additive manufacturing method for manufacturing a heat exchanger

A heat exchanger and additive manufacturing technology, which is applied in the manufacture of heat exchangers and combustion engines, can solve problems such as high cost, complex assembly, and difficult attachment operations, and achieve good tolerances and reduce manufacturing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, this embodiment is provided for thoroughness and completeness. Throughout the specification, the same reference numerals refer to the same elements.

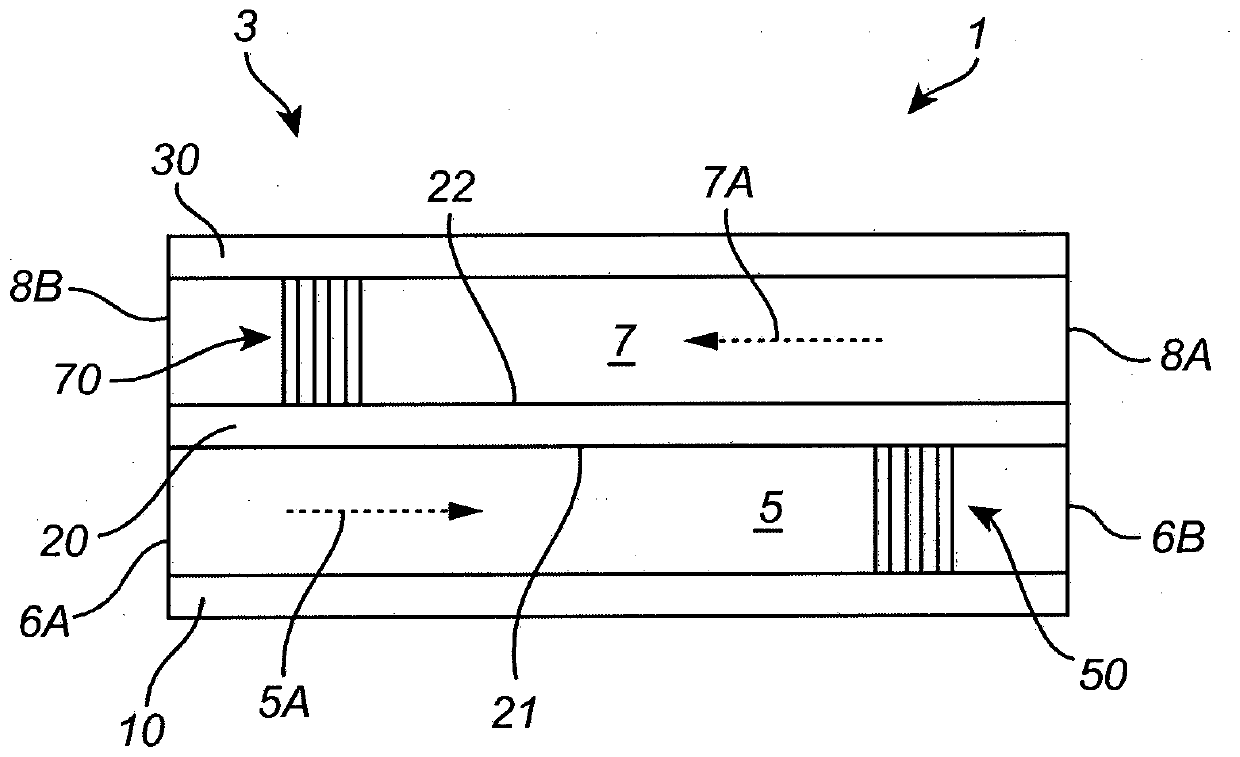

[0085] specific reference figure 1 , a vehicle 800 comprising a heat exchanger 1 and a combustion engine 100 such as an internal combustion engine 100 according to an example of the present invention is provided. figure 1 The vehicle 800 depicted in is a truck 800 for which the inventive concept may be used. However, the inventive concept can also be used in another vehicle, such as construction machinery, such as a wheel loader or excavator, or in another application, such as the process industry or the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com